PET Non Woven Geotextile with Short Fiber

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Non Woven Geotextile with Short Fiber Needle Punched, Find Details about Non Woven Geotextile with Short Fiber Needle Punched and Make an Inquiry for Geotextile at OKorder.com.

Geotextile Specifications:

Geotextile fabrics

Material:polyester/polypropylene fibric

Width:1-9m

Colour:white or black

Use:road ,highway,filter,etc

Weight:100-1500g/m2

Gextextile Description:

--Our geotextile can be made of polypropylene (PP) or polyester (PET) .

-- The weight is available from 100g/m2 to 1500g/m2 and the width from 1m to 8m,

-- Two kinds of processing technical to select: needle punched and thermally bonded, long fiber or short fiber.

-- All kinds of colors are available.

It is widely known as earthwork material and industry fabric, used in the areas of railway, highway, water conservancy, dam, tunnel, subway, environment protection and so on.

-- We can supply different specifications as customers’ request.

Geotextile Specification:

Material: polypropylene (PP) thermally bounded

Weight: 100g/m2-1500g/m2

Width: 1-9m

Length: As customers’ demand (usually is 100m)

Package: PE film and woven cloth

Delivery time: With in 3weeks after received the advance payment

Application of Geotextile:

1. Filtration

The filtration layer of the dykes, river canal, seacoast, concrete slope, retaining walls. At the same time of preventing the clay granule from passing, it allows the water and the gas pass through freely.

2. Separation

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different granule pathway from the groundsill or other buildings.

3. Reinforcement

The highway, railway, soilstone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earth body stability.

4. Protection

It prevents the bank from being washed out, protects the bank and the bottom, prevents the water and soil from being washed away.

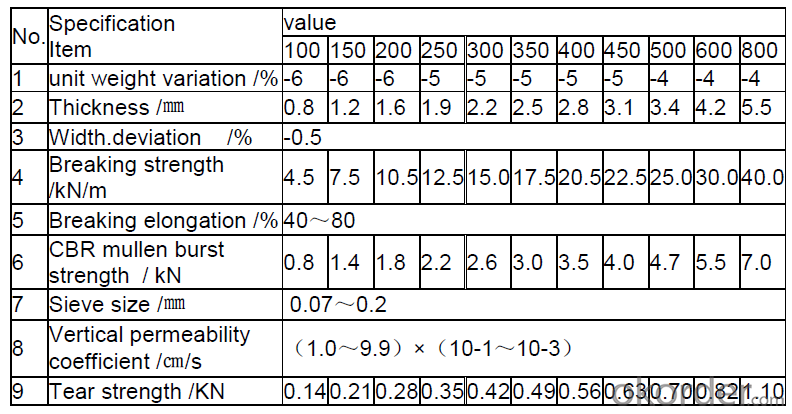

Technical specification of short fiber needle punched non-woven geotextiles:

According to GB/T17638-1998 Standard

Geotextile Specification

Geotextile Show:

Geotextile Show:

RFQ:

- Q: What can we do for the special customer?

A: Provide custom made service with customer's drawing; We make sure to provide you with the best solutions for your individual case. Whether standard items or non-standard items.

- Q: What can we supply?

A: We provide high levels of communication from start to finish.

- Q: What is our advantage?

A: Top Cemented Carbide has extensive business experience, Fast delivery and high quality.

If you want to find more details about the non-woven geotextile, you could make an Inquiry in okorder.com. Okorder.com provides you the products with best price and quality!

- Q:How do geotextiles help with bridge abutment protection?

- Geotextiles help with bridge abutment protection by acting as a barrier to prevent soil erosion and stabilize the surrounding soil. They provide reinforcement and filtration, effectively distributing the load and reducing the risk of settlement and structural damage to the bridge abutments. Additionally, geotextiles can enhance drainage and prevent the clogging of drainage systems, further safeguarding the bridge abutments from water-related issues.

- Q:What are the different installation guidelines for geotextiles in reinforcement projects?

- The installation guidelines for geotextiles in reinforcement projects typically involve preparing the subgrade, ensuring proper overlap and anchoring, and following specific placement techniques. The subgrade should be properly compacted and free from any debris or sharp objects. The geotextile should be installed with sufficient overlap to ensure continuous coverage, and should be securely anchored to prevent movement. Special care should be taken during placement to avoid wrinkles, folds, or damage to the geotextile. Overall, following manufacturer's recommendations and industry best practices is crucial for successful installation of geotextiles in reinforcement projects.

- Q:How are geotextiles used in agricultural applications?

- Geotextiles are used in agricultural applications to stabilize soil, control erosion, and promote proper drainage. They are typically placed beneath soil or gravel surfaces to prevent weed growth and maintain soil structure. Additionally, geotextiles help retain moisture, improve filtration, and mitigate nutrient leaching.

- Q:800g / m2 non-woven geotextile vertical permeability coefficient is generally how much

- 800g / m2 non-woven geotextile vertical permeability coefficient is: 6.1 × 10-2

- Q:Geotextile strength index with interpolation method how to calculate? Then geotextile variation, I do not quite understand, pro, if you know whether to tell me Oh! Very anxious

- Geotextile strong indicators of the interpolation method: For example: geotextile 150 grams of breaking strength is 4.5KN, geotextile 100 grams of breaking strength is 2.5KN, then the geotextile 130 grams of broken strength is how much? The calculation method is: 4.5KN-2.5KN = 2KN (that is, 50 grams of geotextile strength) 2KN by 50 grams multiplied by 30 grams is equal to 1.2KN then geotextile 130 grams of breaking strength is 3.7KN.

- Q:What is geotextile, what role

- Geotextile is a new type of building materials, raw materials are polyester, acrylic, nylon and other polymer polymer synthetic fiber. In accordance with the manufacturing method is divided into: there are two types of geotextile and non-woven geotextile. Geotextile with anti-seepage, anti-filtration, drainage, isolation, reinforcement, protection, sealing and other functions, it with the conventional masonry and concrete material seepage effect compared to a low investment, simple construction process, short duration Infiltration effect is good, the channel effective use of high coefficient. Water conservancy engineering dams and slope protection filter, channel isolation, seepage control; road, railway, airport runway foundation isolation, filter, drainage, slope, retaining wall and road reinforcement, drainage; , Geotextile has been widely used in the field of infrastructure construction, and has been gradually applied in the field of infrastructure construction, and the use of geotextile In a wider area.

- Q:How do geotextiles help in groundwater drainage?

- Geotextiles help in groundwater drainage by allowing water to pass through while preventing soil particles from clogging the drainage system. They act as a filter, providing a barrier against soil erosion and maintaining the permeability of the drainage system, thus improving the overall efficiency of groundwater drainage.

- Q:What are the factors to consider when maintaining geotextiles?

- When maintaining geotextiles, there are several factors to consider. Firstly, it is important to regularly inspect the geotextiles for any signs of damage or wear. This includes checking for tears, holes, or fraying, as well as monitoring the overall condition of the material. Secondly, it is crucial to properly clean the geotextiles to prevent the buildup of dirt, debris, or organic matter that can compromise their effectiveness. This may involve using appropriate cleaning methods such as gentle washing or vacuuming. Additionally, considering the environmental and weather conditions in the specific location where the geotextiles are installed is essential. Extreme temperatures, UV exposure, and moisture levels can impact the durability and longevity of the material, so appropriate protective measures should be taken to mitigate these factors. Lastly, regular maintenance should include reassessing the performance of the geotextiles and their compatibility with the intended application. This may involve consulting with experts or conducting periodic testing to ensure that the geotextiles continue to meet the required standards and objectives. Overall, diligent inspection, cleaning, protection, and evaluation are key factors to consider when maintaining geotextiles.

- Q:How do geotextiles affect soil moisture retention?

- Geotextiles can significantly impact soil moisture retention by acting as a barrier between the soil and the external environment. They help in reducing excessive evaporation from the soil surface, thus minimizing water loss. Additionally, geotextiles prevent the erosion of soil particles, maintaining soil structure and facilitating better water infiltration. This ultimately improves soil moisture retention by creating a more favorable and stable environment for plants to grow.

- Q:Can geotextiles be used in green wall systems?

- Yes, geotextiles can be used in green wall systems. Geotextiles are often used as a barrier or filter to separate the soil from the supporting structure in green wall systems. They provide stability, prevent erosion, and allow for proper drainage, making them a valuable component in the construction and maintenance of green walls.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PET Non Woven Geotextile with Short Fiber

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords