Perfils of Aluminum in Alloy 6063 6061 and Temper T5 T6

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Aluminium is a relatively soft, durable, lightweight, ductile and malleable metal with appearance ranging from silvery to dull gray, depending on the surface roughness. It is nonmagnetic and does not easily ignite. A fresh film of aluminium serves as a good reflector (approximately 92%) of visible light and an excellent reflector (as much as 98%) of medium and far infrared radiation. The yield strength of pure aluminium is 7–11 MPa, while aluminium alloys have yield strengths ranging from 200 MPa to 600 MPa. Aluminium has about one-third the density and stiffness of steel. It is easily machined, cast, drawn and extruded.

Aluminium alloys (or aluminum alloys; see spelling differences) are alloys in which aluminium (Al) is the predominant metal. The typical alloying elements are copper, magnesium, manganese, silicon, tin and zinc. There are two principal classifications, namely casting alloys and wrought alloys, both of which are further subdivided into the categories heat-treatable and non-heat-treatable.

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5-6 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

Products are exported to United States, Canada, U.A.E, Brazil, Mexico,Thailand, Vietnam, Nigeria etc, over 100 countries and regions all over the world.

1. Application of Perfils of Aluminum in Alloy 6063 6061 and Temper T5 T6

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

2. Feature of Perfils of Aluminum in Alloy 6063 6061 and Temper T5 T6

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

3. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

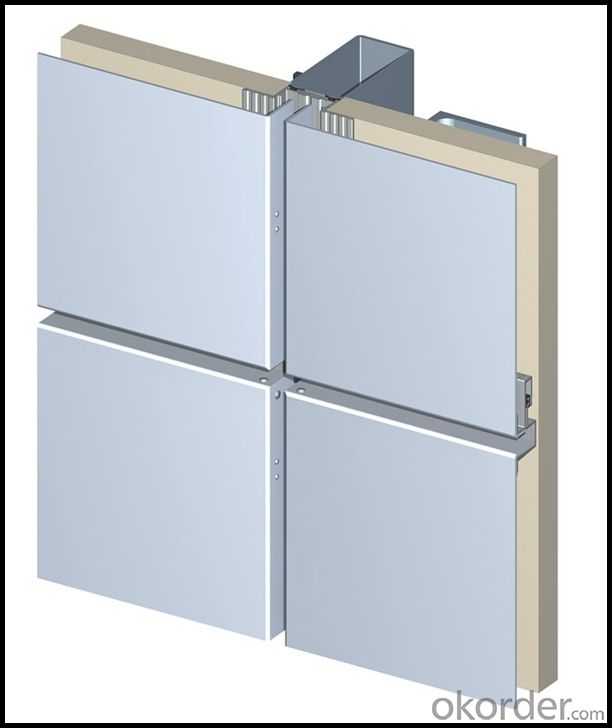

4. Image of Perfils of Aluminum in Alloy 6063 6061 and Temper T5 T6

5. Package and shipping of Perfils of Aluminum in Alloy 6063 6061 and Temper T5 T6

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

- Q:I'm made of aluminum, and I need profiles every month. Where can I buy the information and let the factory take the initiative to find me?

- Can go to the Alibaba website, China aluminum network, HC network, China manufacturing network, Mark Polo network, business treasureGlobal hardware networkMusic for hundredChinese supplierChalcoChinese aluminum netGlobal economic and trade networkWeb sites such as the world trade network will be fine,

- Q:How much is the 60 series aluminum frame bridge standard size, how much is the size of the fan

- 60 series of insulating aluminum window size 60x53.5, window size 67.8x68.6.Distinguish the bridge aluminum, such as 55 series, refers to the broken bridge aluminum window frame width is 5.5 cm, and the aluminum 70 series refers to the broken bridge aluminum window frame width of 7 cm, the main difference between them lies above the insulation wall thickness and the width of aluminum. The aluminum 55 series and 60 series of wall thickness is the national standard 1.4MM, aluminum doors and windows insulation insulation than 60 series 55 series terms 0.5 cm, aluminum wall thickness, the difference is not, but the 55 series and 70 series of different, one is the 70 series of more than 55 of the width to 1.5 cm wide, the second is the aluminum 70 series aluminum wall thickness is 1.8MM, far better than the national standard.Hollow glass aluminum doors and windows 55 models for 5+12A+5 glass, the middle interval is 12, while the hollow glass interval of 70 series aluminum doors and windows 22, so the aluminum 70 series 55 series of aluminum than sound better. The use of aluminum in the family model 55 is enough, this is the standard engineering materials, which is the most common type of use, if the noise requirements higher, it can be considered by the German red card 70 series of ten sealing design, especially along the street district is relatively high requirements on the sound. Is the best choice.

- Q:Are aluminum profiles suitable for bathroom fittings and accessories?

- Yes, aluminum profiles are suitable for bathroom fittings and accessories. Aluminum is a versatile material that is corrosion-resistant, lightweight, and durable, making it an ideal choice for bathroom fittings. Aluminum profiles can be used for various bathroom accessories such as towel racks, shower curtain rods, soap dispensers, and shelves. Additionally, aluminum can be easily shaped and molded into different designs and finishes, allowing for customization and aesthetic appeal. Its resistance to moisture and humidity also makes it a suitable choice for bathroom environments. Overall, aluminum profiles provide a practical and stylish solution for bathroom fittings and accessories.

- Q:What are the different surface embossing options for aluminum profiles?

- There are several surface embossing options available for aluminum profiles, each offering unique textures and patterns. Some of the most commonly used options include: 1. Diamond pattern: This embossing option creates a diamond-shaped pattern on the surface of the aluminum profile. It provides a visually appealing texture and enhances the grip of the profile, making it suitable for applications that require slip resistance. 2. Stucco pattern: Stucco embossing creates a textured surface with small, raised bumps. This pattern is commonly used in applications where aesthetics are important, such as architectural facades or interior design elements. 3. Hammer tone pattern: This embossing option creates a hammered texture on the surface of the aluminum profile. It gives a unique and rustic appearance, making it popular for decorative applications like furniture or light fixtures. 4. Wood grain pattern: Wood grain embossing mimics the texture and appearance of natural wood. This option is often chosen to achieve a more traditional or natural look in applications like window frames or doors. 5. Linen pattern: Linen embossing creates a subtle, fabric-like texture on the surface of the aluminum profile. This pattern is commonly used in applications that require a sophisticated and elegant finish, such as interior decorative panels or cabinet doors. It's important to note that these embossing options can be combined or customized to suit specific design requirements. Manufacturers may offer additional embossing options, allowing customers to choose from a wide range of patterns and textures to achieve their desired aesthetic and functional goals.

- Q:Can aluminum profiles be used for transportation applications?

- Yes, aluminum profiles can be used for transportation applications. Aluminum is a lightweight and durable material, making it ideal for various transportation purposes. It is commonly used in the construction of vehicles, including cars, trucks, trains, airplanes, and ships. Aluminum profiles can be used to create strong and rigid structures, reducing the overall weight of the vehicle, which in turn improves fuel efficiency and reduces emissions. Additionally, aluminum is resistant to corrosion, making it suitable for outdoor and maritime applications. The versatility and strength of aluminum profiles make them a popular choice in the transportation industry.

- Q:Can aluminum profiles be used in the construction of exhibition booths?

- Yes, aluminum profiles can be used in the construction of exhibition booths. Aluminum profiles are lightweight, durable, and versatile, making them an ideal choice for constructing modular exhibition booths. These profiles can be easily assembled and disassembled, allowing for easy transportation and reconfiguration of the booth layout. Additionally, aluminum profiles offer a sleek and modern aesthetic, providing a professional and visually appealing display for exhibitors. They can be used to create frames, partitions, shelving, signage, and various other components required for exhibition booths. Overall, aluminum profiles offer a cost-effective and efficient solution for constructing exhibition booths.

- Q:What are the different packaging options available for aluminum profiles?

- There are several packaging options available for aluminum profiles, including individual poly bags, cardboard tubes, wooden crates, or pallets. These options ensure the protection and safe transportation of the aluminum profiles.

- Q:What kinds of profiles are made of aluminium alloy windows?

- If the outer frame is used, slide, slide and seal;Internal fan, then use the upper horizontal, lower horizontal, hook enterprises, light EnterprisesThis is used for ordinary sliding windows and sliding doors. If the window is bright, use the layeringFour open the window, but also in a spell, in fact, there are some materials, but not commonly used, so do not say moreIf you do casement window, it depends on what you want to do,

- Q:What are the advantages of using aluminum profiles in the mining industry?

- Using aluminum profiles in the mining industry offers several advantages. To begin with, aluminum profiles possess a combination of lightweight and strong characteristics, making them an ideal choice for mining equipment. This enables easier transportation and installation of machinery, resulting in increased efficiency and cost reductions. Furthermore, aluminum profiles exhibit a high resistance to corrosion. In the mining industry, where equipment is exposed to harsh environments and corrosive substances, this becomes a significant advantage. The durability of aluminum profiles ensures that mining equipment remains in good condition for extended periods, thereby reducing maintenance and replacement expenses. Moreover, aluminum profiles are non-magnetic, which is crucial in mining operations involving magnetic materials like iron ore. This prevents any interference with sensitive mining equipment, ensuring accurate measurements and efficient operations. Additionally, aluminum profiles offer a high level of versatility and can be easily customized to meet the specific requirements of mining operations. They can be machined, welded, and formed into various shapes and sizes, allowing for the creation of tailor-made structures and equipment. This flexibility promotes innovation and optimization within the mining industry. Furthermore, aluminum profiles possess excellent thermal conductivity. In mining applications where temperature control is essential, such as in smelting or refining processes, this property proves advantageous. Aluminum profiles effectively dissipate heat, preventing equipment from overheating and ensuring optimal performance. Lastly, aluminum profiles contribute to sustainability in the mining industry. Aluminum is a widely recycled material, and its use in mining promotes a circular economy and reduces environmental impact. The recyclability of aluminum profiles also offers long-term cost savings. In conclusion, the use of aluminum profiles in the mining industry provides numerous benefits, including their lightweight yet strong nature, resistance to corrosion, non-magnetic properties, versatility, thermal conductivity, and sustainability. These advantages contribute to improved efficiency, cost reductions, and enhanced environmental performance in mining operations.

- Q:What are the different packaging options for aluminum profiles?

- Some of the different packaging options for aluminum profiles include bundles or packs wrapped in plastic or stretch film, wooden crates or pallets, cardboard boxes, and custom-designed packaging solutions for specific profiles or customer requirements.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Perfils of Aluminum in Alloy 6063 6061 and Temper T5 T6

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords