PE Solid and Metallic Color Coated Aluminium Coils with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

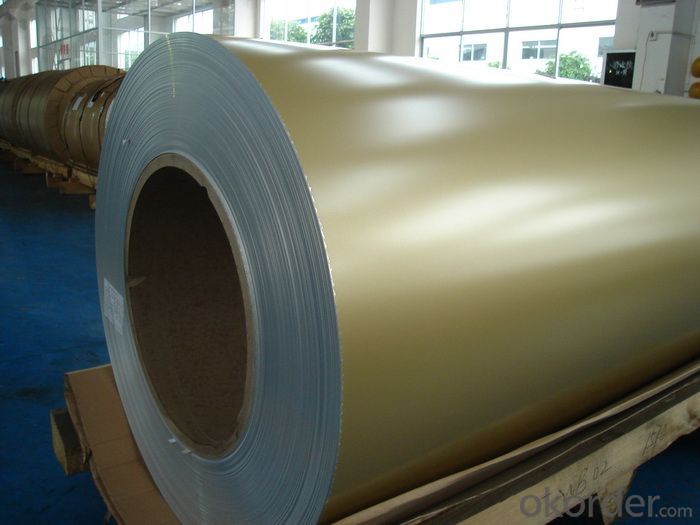

1. Structure of PE Solid and Metallic Color Coated Aluminium Coils with High Quality

PE solid and metallic color coated aluminium coils are with excellent acid-resistance and alkali-resistance. They have super characters in environment protection, flame-resistance, and groovy colors.

PE solid and metallic color coated aluminium coils are widely used for aluminum composite panels. We normally use alloy 3003 and temper H16.

We have different colors for aluminum composite panels. RAL numbers are no problem for us. We also can adjust coating according to color of customers and offer personalized services.

2. Main Features of PE Solid and Metallic Color Coated Aluminium Coils with High Quality

• Light Weight

• Good in strength and rigidity

• High Flatness

• Good Weathering

• Colorful

• Recycling

• Saving Energy

• Rust proof

3. PE Solid and Metallic Color Coated Aluminium Coils with High Quality Images

4. Specification of PE Solid and Metallic Color Coated Aluminium Coils with High Quality

ALLOY | TEMPER | THICKNESS | WIDTH | COATING and COLOR |

3003, 3105, etc | H44, etc | 0.2-0.6mm | Less than1600mm | AS PER YOUR REQUIREMENTS |

5. FAQ

A.What about inspections to guarantee quality?

For each order, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported?

We have exported to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q:What is the cost-effectiveness of using aluminum coils compared to other materials?

- The cost-effectiveness of using aluminum coils compared to other materials is generally favorable. Aluminum coils are lightweight, durable, and corrosion-resistant, which reduces maintenance and replacement costs. They also have excellent heat transfer properties, leading to energy efficiency and cost savings in heating and cooling systems. Additionally, aluminum is a widely available and recyclable material, lowering the overall cost and environmental impact.

- Q:I want to separate the copper and aluminum so I will get more at the scrap yard for my radiators any one know of an easy way to do this? Thanks

- I do not think its worth it. Radiators in whole ar going for around $1.28 per lb. For current pricing go to www.scrapmetalpricesandauctions.c...

- Q:What are the insulation options available for aluminum coils?

- There are various insulation options available for aluminum coils, including fiberglass insulation, foam insulation, and elastomeric insulation. These insulation materials help to improve the energy efficiency of the coils and prevent condensation or heat loss.

- Q:Which type of wheel is more durable, long-lasting and which wheel type would cost more, Aluminum or chrome?

- chrome would cost more because the rim has to be purchased polished and have chromed. aluminum gets damaged easier.

- Q:What is the typical yield strength of aluminum coils?

- The yield strength of aluminum coils can differ based on the specific alloy and temper employed, resulting in varying typical values. Nevertheless, for numerous widely used aluminum alloys, the yield strength usually falls within the range of 15,000 psi to 40,000 psi (100 MPa to 275 MPa). It is crucial to acknowledge that this range is a general approximation, and variations may exist among distinct aluminum coil products. Furthermore, the yield strength can be affected by variables like coil thickness and processing conditions.

- Q:What are the common recycling methods for aluminum coils?

- The common recycling methods for aluminum coils include sorting them based on their alloy composition, melting them down to remove any impurities, and then reusing the molten aluminum to make new coils or other aluminum products.

- Q:Can aluminum coils be used for signage purposes?

- Signage purposes can indeed utilize aluminum coils. Aluminum, as a lightweight and versatile material, finds common use in the signage industry. It possesses exceptional resistance to corrosion, rendering it suitable for both indoor and outdoor applications. Aluminum coils are easily cut and molded into diverse shapes and sizes, enabling the creation of customized signage designs. Moreover, aluminum exhibits high durability and can endure harsh weather conditions, ensuring longevity for signage. Coils can be painted or coated with various finishes to achieve desired aesthetics, while simultaneously safeguarding against fading and scratching. Ultimately, aluminum coils remain a favored choice for signage due to their versatility, durability, and aesthetic appeal.

- Q:Some makes like KIA make a point of having aluminum engines. I thought this was for weight, but was more prone to failure, especially in a high mileage car.

- Aluminium engines have a lot of steel parts in it ( crank shaft. connecting rods, cam shafts etc. These parts take the most wear. The only real problem with aluminium engines is over heating. Aluminium will warp quicker than cast steel blocks.

- Q:What are the standard tolerance levels for aluminum coils?

- The standard tolerance levels for aluminum coils can vary depending on the specific industry and application. However, in general, the tolerance levels for aluminum coils are determined by industry standards and specifications such as ASTM (American Society for Testing and Materials) or ISO (International Organization for Standardization). For thickness, the standard tolerance levels for aluminum coils can range from +/- 0.002 inches to +/- 0.020 inches, depending on the specific grade and thickness of the aluminum. Similarly, for width, the tolerance levels can vary from +/- 0.010 inches to +/- 0.250 inches. In terms of flatness, the standard tolerance levels for aluminum coils are typically specified as a maximum deviation from a flat plane. This can range from as low as 0.001 inches to as high as 0.020 inches, depending on the specific requirements of the application. Other factors that may influence tolerance levels include the surface finish, edge condition, and mechanical properties of the aluminum coils. It is important to consult the relevant industry standards and specifications, as well as the specific requirements of the application, to determine the appropriate tolerance levels for aluminum coils.

- Q:Can aluminum coils be used in coil coating processes?

- Yes, aluminum coils can be used in coil coating processes. Coil coating is a continuous and automated process that involves applying a protective or decorative coating to a coil of metal, typically steel or aluminum. Aluminum coils are commonly used in this process due to their excellent corrosion resistance, lightweight nature, and ease of forming. The aluminum coils undergo various pre-treatment processes like cleaning, chemical treatment, and primer application before the actual coating is applied. These coils are then coated with a wide range of materials, including paints, lacquers, and polymers, to enhance their appearance, durability, and performance. The coil coating process allows for efficient and consistent coating application, making it an ideal choice for various industries such as construction, transportation, and appliances.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PE Solid and Metallic Color Coated Aluminium Coils with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords