Alu Stock, Casting Coil Stock

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

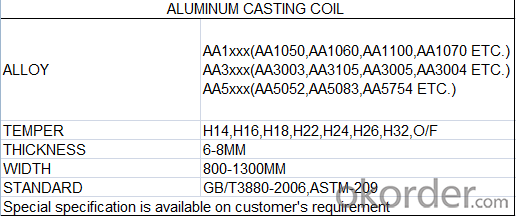

1.Structure of Alu Stock, Casting Coil Stock:

Alu Stock, Casting Coil Stock for thin coil and sheet is used in the factories that produce aluminum coil from 0.2mm to 6mm by thickness. Hot rolled y cold rolled son available. The thickness of Alu Stock, Casting Coil Stockis about 6-8mm. You can choose the alloys as your using and we will do our best to meet your requests.

2.Main Features of the Alu Stock, Casting Coil Stock :

• Smooth surface

• High manufacturing accuracy

• High strength of extension and yield

• Low tolerance

• Strict quality control

• Well packaged

3. Alu Stock, Casting Coil Stock

4. Production Process of Alu Stock, Casting Coil Stock

Cold Rolled

Hot rolled

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① What is the MOQ of Aluminum Casting Coil

Usually the MOQ is 150 tons, but we also can make solution according to clients’ situation.

②How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines.

Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

③Can you guarantee the quality of the products?

We are responsible for the quality of materials in a reasonable period of time to get a long-term cooperation with clients and we are glad to arrange and coordinate any third party inspection for you.

④What is the delivery time after purchase?

15 day with normal specification after receiving client’s deposit or correct LC

- Q:I think the use of aluminum, at the lower levels, has really hurt US born players. To give a kid a piece of metal, and expect him to use wood when drafted........ I think US should go back to wood, whatever the costs (I know the aluminum is far cheaper). Thoughts....Cheers.

- Maybe. Remember, there are still tons of American born players who are some of the top players in the league. Mark Teixeira, David Wright, Ryan Braun, and many others. Also, while the use of aluminum bats may hurt American position players, pitching is completely dominated by Americans. Tim Lincecum, CC Sabathia, Cole Hamels, Ryan Dempster, Jake Peavy, Scott Kazmir. The problem is that like you said aluminum is cheaper and players are used to them. Also with aluminum bats you can have bats as light as 18 ounces and as heavy as 30 or more ounces, so kids can start using aluminum bats from an early age and not want to switch to wood. I think what they should at least do is take aluminum bats out of college baseball.

- Q:Can aluminum coils be used in the manufacturing of lighting fixtures?

- Yes, aluminum coils can be used in the manufacturing of lighting fixtures. Aluminum is a versatile and lightweight material that has excellent thermal conductivity properties, making it suitable for dissipating heat generated by the light source. Additionally, aluminum coils are easily moldable, allowing for the creation of intricate designs and shapes in lighting fixtures. The corrosion-resistant nature of aluminum also ensures the longevity and durability of the lighting fixture. Overall, aluminum coils are a popular choice in the manufacturing of lighting fixtures due to their numerous advantages.

- Q:What is the role of aluminum coils in the construction of ships?

- Aluminum coils are used in the construction of ships primarily for their lightweight and corrosion-resistant properties. They are commonly used in the fabrication of ship hulls, decks, and superstructures. The use of aluminum coils reduces the overall weight of the ship, improving fuel efficiency and increasing payload capacity. Additionally, the corrosion resistance of aluminum helps to prolong the lifespan of the ship, reducing maintenance costs in the long run.

- Q:Are aluminum coils suitable for high-reflective applications?

- Yes, aluminum coils are suitable for high-reflective applications. Aluminum is known for its excellent reflectivity, with a reflectance ratio of around 80-90%. This makes it an ideal material for applications that require high reflectivity, such as in lighting fixtures, solar panels, and mirrors. Aluminum coils can be coated or polished to further enhance their reflective properties. Additionally, aluminum is lightweight, corrosion-resistant, and has good heat conductivity, making it a versatile choice for various high-reflective applications.

- Q:Can aluminum coils be used in the production of aluminum composite roofs?

- Yes, aluminum coils can be used in the production of aluminum composite roofs. Aluminum coils are commonly used in the manufacturing process of aluminum composite roofs due to their durability, lightweight nature, and ability to resist corrosion. The coils can be easily formed and shaped into the desired profile for the roof, ensuring a seamless and aesthetically pleasing finish. Additionally, aluminum offers excellent thermal and sound insulation properties, making it an ideal choice for roofing applications. Its high strength-to-weight ratio also contributes to the overall structural integrity of the roof. Overall, using aluminum coils in the production of aluminum composite roofs provides a reliable and long-lasting roofing solution.

- Q:Can aluminum coils be formed or shaped?

- Yes, aluminum coils can be formed or shaped.

- Q:How do you store and transport aluminum coils?

- Aluminum coils are typically stored and transported using a few different methods to ensure their safety and prevent damage. When it comes to storage, it is essential to keep the coils in a dry, clean, and well-ventilated area to avoid any moisture-related issues or corrosion. Ideally, the storage area should have a controlled temperature to prevent any extreme fluctuations that could affect the quality of the aluminum. To protect the coils from physical damage, they should be stored horizontally or vertically on a stable and level surface. It is crucial to avoid stacking them too high to prevent any potential collapse and ensure easy access for inspection or transportation purposes. Additionally, placing them on wooden pallets or racks with proper spacing between each coil can provide extra stability and protection. When it comes to transporting aluminum coils, there are several options available depending on the quantity, distance, and mode of transportation. For short distances or smaller quantities, hand trucks or forklifts can be used to move the coils onto a flatbed truck or a van. It is important to secure the coils properly using straps or bands to prevent any movement during transit. For larger quantities or longer distances, the coils can be transported using specialized coil carriers. These carriers are designed to securely hold multiple coils in an organized manner, limiting any potential damage caused by vibration or shifting during transportation. They are typically equipped with side rails and restraining bars to secure the coils in place. Regardless of the method used for transportation, it is crucial to handle the aluminum coils with care and ensure they are adequately protected. Regular inspections should be conducted before, during, and after transportation to identify any signs of damage or issues that could compromise the integrity of the coils. By following these guidelines, the storage and transportation of aluminum coils can be done efficiently and safely.

- Q:How are aluminum coils processed and shaped into different forms?

- To shape aluminum coils into various forms, a series of processes is undergone. Initially, the coils are uncoiled and straightened in the uncoiling process, facilitating easier handling and further processing. Following this, a cleaning process is conducted to eliminate any dirt, grease, or impurities present on the coil's surface. This step guarantees a smooth and clean finish for the final product. After cleaning, the coil usually undergoes a sequence of heat treatments to enhance its mechanical properties. This process, known as annealing, entails heating the coil to a specific temperature and gradually cooling it down. Annealing increases the aluminum's ductility, making it more pliable and easier to shape. Once annealed, the coil can be shaped into different forms using various techniques. One prevalent approach is roll forming, where the coil is passed through a series of rollers that gradually bend and shape it according to the desired form. Roll forming is commonly utilized for producing sheets, strips, or tubes. Another popular technique is stamping, which involves utilizing a die and press to cut or shape the aluminum coil into specific shapes. Stamping is frequently employed to create intricate designs or components with precise dimensions. Aside from roll forming and stamping, other methods like extrusion, bending, and welding can also be employed to shape aluminum coils into different forms. These processes enable the production of a vast range of products, including automotive parts, household appliances, and construction materials. Overall, the processing and shaping of aluminum coils encompass a combination of cleaning, heat treatment, and diverse forming techniques. These processes ensure that the aluminum is transformed into the desired form while maintaining its structural integrity and desired properties.

- Q:What is the coefficient of thermal expansion of aluminum coils?

- The coefficient of thermal expansion of aluminum coils is typically around 23 x 10^-6 per degree Celsius.

- Q:im looking for a bat but i dont know what to get wood or aluminum what is harder wood or aluminum ?? what would be better for hitting hard balls with ( or maybe people ) haha no im joking i need help !!!!

- why dont get wack each one over your head and see which hurts more. than you'll get your answer, just kidding. you should know metal is always harder than wood. but for baseball, you want a wooden bat, better for the swing, and the grip. I used to play little league back in the day and used aluminum bats, and even with batting gloves my hands were always killing me after the game.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Alu Stock, Casting Coil Stock

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords