All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

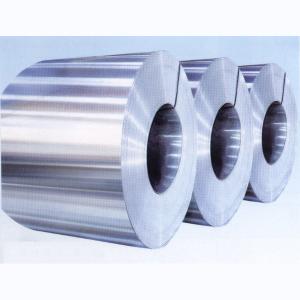

What are the advancements in aluminum coil technology for electrical applications?

Advancements in aluminum coil technology for electrical applications include improved conductivity, enhanced insulation properties, and increased durability. New manufacturing processes and alloy compositions have resulted in coils that offer higher electrical efficiency and lower resistance, leading to reduced energy losses. Additionally, advancements in insulation materials and coatings have made aluminum coils more resistant to electrical and thermal stress, ensuring better performance and longevity in various electrical applications.

How are aluminum coils anodized for corrosion resistance?

Aluminum coils are anodized for corrosion resistance by subjecting them to an electrolytic process. This involves immersing the coils into a bath containing an electrolyte solution, while an electric current is passed through the solution. The coils act as the anode in this process. As a result, an oxide layer is formed on the surface of the aluminum, which enhances its corrosion resistance properties. This anodized layer not only provides a protective barrier against environmental factors but also improves the aesthetic appearance of the aluminum coils.

What are the quality control measures for the dimensions and tolerances of aluminum coils?

The quality control measures for the dimensions and tolerances of aluminum coils involve several steps. Firstly, during the production process, manufacturers use precise machinery and tools to ensure accurate dimensions. They regularly calibrate and maintain these machines to prevent any variations in measurements.

Next, random samples of the aluminum coils are taken from the production line and thoroughly inspected using measuring instruments such as calipers, micrometers, and gauges. These instruments are capable of measuring the dimensions and tolerances of the coils with high precision. The measurements are compared against the specified dimensional requirements and tolerances provided by the customer or industry standards.

If any discrepancies are found, the coils are rejected or adjusted accordingly to meet the required specifications. This ensures that only coils within the acceptable range of dimensions and tolerances are released for further processing or shipment.

Additionally, some manufacturers also conduct periodic audits and quality checks to monitor the consistency and accuracy of their dimensional control processes. These audits involve independent inspections to verify that the coils meet the specified dimensions and tolerances consistently over time.

Overall, the quality control measures for the dimensions and tolerances of aluminum coils involve a combination of precision machinery, regular calibration, random inspections, and periodic audits to ensure that the coils conform to the desired specifications.

Wholesale Aluminum Coils from supplier in Yemen

We are a Aluminum Coils supplier serving the Yemen, mainly engaged in the sale, quotation, and technical support services of various Aluminum Coils products in the Yemen region. We are a subsidiary platform of the Fortune Global 500 company CNBM, able to provide you with one-stop Aluminum Coils procurement services in the Yemen. Not only do we have a wide range of Aluminum Coils products, but after years of market development in the Yemen, we can also provide valuable experience for your projects.