All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What innovative applications of aluminum profiles exist in the development of electric vehicles?

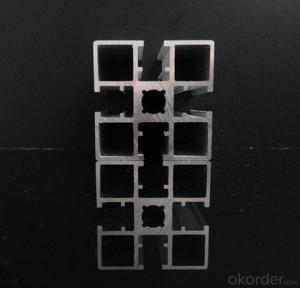

One innovative application of aluminum profiles in the development of electric vehicles is the use of extruded aluminum for lightweight structural components. Aluminum profiles are often utilized in the chassis and body of electric vehicles to reduce weight and improve overall energy efficiency. This lightweight construction allows for increased range and better performance of the vehicle. Additionally, aluminum profiles can be easily shaped and integrated into complex designs, providing flexibility for electric vehicle manufacturers to create sleek and aerodynamic exteriors. Overall, the use of aluminum profiles in electric vehicle development helps to achieve higher efficiency, longer range, and improved sustainability in the transportation industry.

What is the role of aluminum profiles in the construction of energy-efficient healthcare facilities and hospitals?

Aluminum profiles play a crucial role in the construction of energy-efficient healthcare facilities and hospitals. They are used in various applications such as windows, doors, curtain walls, and partitions, contributing to the overall energy efficiency of the building. Aluminum profiles have excellent thermal insulation properties, which help in reducing heat transfer, thereby minimizing energy consumption for heating and cooling. Additionally, these profiles are lightweight, durable, and corrosion-resistant, ensuring long-term performance and low maintenance costs. Their versatility and design flexibility enable the creation of modern, aesthetically pleasing healthcare facilities while prioritizing energy efficiency and sustainability.

What measures are taken to protect aluminum profiles against galvanic corrosion?

One common measure to protect aluminum profiles against galvanic corrosion is by applying a protective coating or finish. This can be done through processes such as anodizing, which creates a layer of oxide on the surface of the aluminum, or by using chemical conversion coatings. Additionally, isolating dissimilar metals through the use of insulating materials or coatings can also prevent galvanic corrosion. Regular maintenance and inspection of the aluminum profiles is important to identify any potential corrosion areas and take necessary corrective actions.

Wholesale Aluminum Profiles from supplier in Cambodia

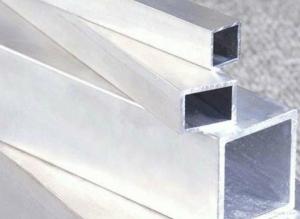

Whether you are in the construction, manufacturing, or architectural industry, we have the expertise to cater to your specific requirements. Our Aluminum Profiles are made from high-quality materials and are available in various shapes, sizes, and finishes to suit your needs.

We understand that every project is unique, and our team of experts is dedicated to providing personalized solutions that meet your exact specifications. From initial consultation to final delivery, we are committed to ensuring that you receive the highest level of service and satisfaction.

Our sales team is available to assist you with any inquiries or quotations you may need. We can also provide technical support, offering guidance and advice to help you make informed decisions about the aluminum profiles that best suit your project.

As part of CNBM, a global leader in the aluminum industry, we have access to a wide network of suppliers and resources. This allows us to offer competitive prices and efficient procurement services, ensuring that your projects stay on schedule and within budget.

Whether you are looking for standard aluminum profiles or custom-made solutions, we have the capabilities to meet your needs. Contact us today to discuss your requirements and let us be your trusted partner for aluminum profile procurement in Cambodia.

We understand that every project is unique, and our team of experts is dedicated to providing personalized solutions that meet your exact specifications. From initial consultation to final delivery, we are committed to ensuring that you receive the highest level of service and satisfaction.

Our sales team is available to assist you with any inquiries or quotations you may need. We can also provide technical support, offering guidance and advice to help you make informed decisions about the aluminum profiles that best suit your project.

As part of CNBM, a global leader in the aluminum industry, we have access to a wide network of suppliers and resources. This allows us to offer competitive prices and efficient procurement services, ensuring that your projects stay on schedule and within budget.

Whether you are looking for standard aluminum profiles or custom-made solutions, we have the capabilities to meet your needs. Contact us today to discuss your requirements and let us be your trusted partner for aluminum profile procurement in Cambodia.