All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the effects of 3D printing technology on the customization and production of steel strips?

The effects of 3D printing technology on the customization and production of steel strips are significant. With 3D printing, steel strips can be customized and produced with a high level of precision and complexity, allowing for the creation of intricate designs and shapes that were previously difficult or impossible to achieve through traditional manufacturing methods. This technology also enables faster and more cost-effective production processes, reducing lead times and allowing for on-demand manufacturing. Furthermore, 3D printing allows for the optimization of material usage, resulting in less waste and increased sustainability. Overall, the introduction of 3D printing technology has revolutionized the customization and production of steel strips, offering greater flexibility, efficiency, and innovation in the manufacturing industry.

What is the process of coil coating in steel strip manufacturing?

Coil coating is a highly efficient and controlled process used in steel strip manufacturing. It involves the application of a protective coating onto a continuous steel strip, which is then coiled for further processing. The process begins with cleaning the steel strip to remove any contaminants and preparing the surface for coating. Next, a primer is applied to enhance adhesion and corrosion resistance. After that, a topcoat is applied, which can be customized to provide specific properties such as durability, color, or reflectivity. The coated steel strip is then cured through a high-temperature oven, ensuring the coatings' proper bonding and curing. Finally, the coil is cooled, inspected, and prepared for shipment to various industries for further fabrication. Overall, coil coating offers excellent uniformity, durability, and versatility in protecting and enhancing the performance of steel strips.

What are the specifications for steel strips used in medical equipment manufacturing?

The specifications for steel strips used in medical equipment manufacturing typically include requirements such as high strength and corrosion resistance, precise dimensional tolerances, and compliance with relevant industry standards such as ASTM or ISO. Additionally, the specific alloy composition and surface finish may vary depending on the intended application within the medical equipment.

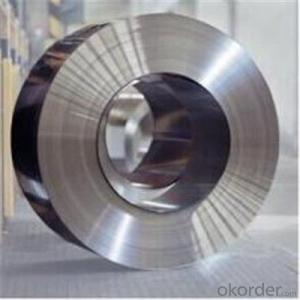

Wholesale Steel Strips from supplier in Cambodia

Whether you are in the construction, manufacturing, or automotive industry, our Steel Strips are of the highest quality and meet international standards. We offer a variety of steel strip products, including hot-rolled steel strips, cold-rolled steel strips, galvanized steel strips, and stainless steel strips.

At our company, we understand the importance of timely and reliable delivery. That is why we have established a strong logistics network to ensure that your steel strips reach you in a timely manner, no matter where you are in Cambodia. Our team of dedicated professionals will work closely with you to understand your specific requirements and provide tailored solutions to meet your needs.

In addition to our sales and quotation services, we also offer technical support to assist you in selecting the right steel strips for your projects. Our team of experts has in-depth knowledge and experience in the steel industry, and they will be able to provide you with valuable advice and guidance throughout the procurement process.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and expertise. This allows us to stay up-to-date with the latest industry trends and developments, ensuring that we can offer you the most innovative and cost-effective solutions for your steel strip needs.

When you choose us as your steel strip supplier in Cambodia, you can expect exceptional customer service, top-quality products, and competitive prices. We are committed to building long-term partnerships with our clients and strive to exceed their expectations in every aspect of our service.

Contact us today to discuss your steel strip requirements in Cambodia. We look forward to working with you and contributing to the success of your projects.

At our company, we understand the importance of timely and reliable delivery. That is why we have established a strong logistics network to ensure that your steel strips reach you in a timely manner, no matter where you are in Cambodia. Our team of dedicated professionals will work closely with you to understand your specific requirements and provide tailored solutions to meet your needs.

In addition to our sales and quotation services, we also offer technical support to assist you in selecting the right steel strips for your projects. Our team of experts has in-depth knowledge and experience in the steel industry, and they will be able to provide you with valuable advice and guidance throughout the procurement process.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and expertise. This allows us to stay up-to-date with the latest industry trends and developments, ensuring that we can offer you the most innovative and cost-effective solutions for your steel strip needs.

When you choose us as your steel strip supplier in Cambodia, you can expect exceptional customer service, top-quality products, and competitive prices. We are committed to building long-term partnerships with our clients and strive to exceed their expectations in every aspect of our service.

Contact us today to discuss your steel strip requirements in Cambodia. We look forward to working with you and contributing to the success of your projects.