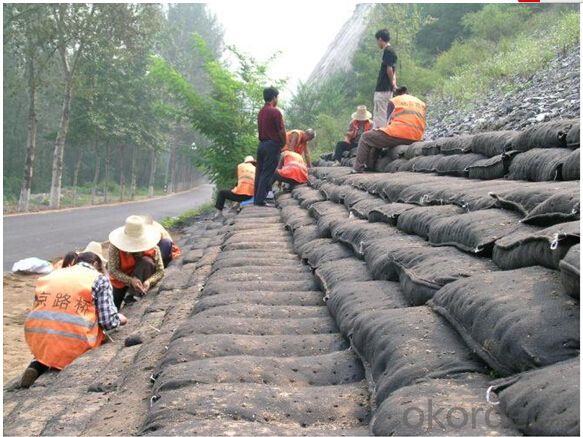

Non Woven Geo Bag Used in Embankment Protection

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Product Introudction of Geo Bag: Geotextile sand bag made of PE or PP, with good corrosion resistance ,excellent chemical resistance,the UV resistance. The products can be applied in construction projects such as water conservancy projects,river bank protection, dams, road and railway project, airport, environmental protection projects, in which play the important role of filtration, drainage, separability, and reinforcement. 2. Technical Sheet of Geo Bag: TESTS TEST STANDARD UNIT VALUES WEIGHT ASTMD 5261 : (99) 2009 GSM >400 THICKNESS MM 3 TENSILE STRENGTH BS EN ISO: 10319: 2008 KN/m >17 ELONGATION AT MAX. FORCE (MD) BS EN ISO: 10319: 2008 % > 60% & 100% ELONGATION AT MAX. FORCE (CMD) BS EN ISO: 10319: 2008 % >3300 CBR PUNTURE RESISTANCE BF EN ISO: 12236: 2006 N 34 x 103- WATER PERMEABILITY EN ISO : 11058 :1999 m/s >85% of original tensile strength before exposure UV RESISTANCE ASTMD4355 ³ % >95 ABRASIVE RESISTANCE %

3. FAQ of Geo Bag:

Q1. How is the delivery time?

Delivery: Within 2 weeks upon the receipt of the deposit.

Q2. What's are the MOQ?

The MOQ is different for different products, for our first cooperation we can accept your first trial order volume.

Q3. Are the free samples availale?

Yes, the free samples are available. We will charge the express fee based on the area sent, your express account is the top choice for samples sending

- Q:What are the specifications for geotextiles in wastewater treatment projects?

- Geotextiles used in wastewater treatment projects typically have specific specifications related to their weight, permeability, and durability. These specifications ensure that the geotextiles are capable of providing effective filtration, separation, and reinforcement functions in the wastewater treatment process. Additionally, they are designed to withstand the harsh conditions and chemicals present in wastewater treatment facilities.

- Q:How do geotextiles improve the performance of embankments?

- Geotextiles improve the performance of embankments by providing reinforcement, filtration, and separation. They prevent the intermixing of different soil layers by acting as a barrier, thus enhancing the stability and reducing the settlement of the embankment. Additionally, geotextiles allow for the efficient drainage of water, preventing the buildup of excess pore pressure that could potentially lead to embankment failure.

- Q:What are the benefits of using geotextiles in erosion control?

- Geotextiles offer several benefits in erosion control, including their ability to prevent soil erosion, stabilize slopes, and promote vegetation growth. They act as a barrier against water flow, reducing the impact of rainfall and preventing sediment runoff. Geotextiles also enhance soil reinforcement by distributing load and reducing soil movement. Furthermore, they allow for better filtration and drainage, improving water quality and reducing the risk of flooding. Overall, geotextiles provide cost-effective and environmentally friendly solutions for erosion control.

- Q:What are the design considerations for geotextile-reinforced pavement systems?

- Some of the key design considerations for geotextile-reinforced pavement systems include selecting the appropriate type and quality of geotextile, determining the required reinforcement strength, considering the expected traffic loads and patterns, evaluating the subgrade conditions, ensuring proper installation and compaction of the geotextile, and assessing long-term durability and maintenance requirements. Additionally, factors such as drainage, stability, and environmental impact should also be taken into account during the design process.

- Q:What are the different geotextile manufacturing processes?

- There are several different geotextile manufacturing processes, including needle punching, thermal bonding, and weaving.

- Q:Can geotextiles be used in mine tailings dewatering applications?

- Yes, geotextiles can be used in mine tailings dewatering applications. Geotextiles are commonly used in mining operations to separate and filter solids from liquids, including in the dewatering of mine tailings. They can effectively retain fine particles while allowing water to pass through, aiding in the process of dewatering and facilitating the management and disposal of mine tailings.

- Q:What is the effect of highway geotextile on highway construction?

- Highway geotextile is a new type of civilized artifacts in the construction of the time, laying highway geotextile can improve the carrying capacity of the road, can improve the use of the road in the process of structural damage. As the geotextile has the role of shock absorption, and has a high elasticity and resistance to deformation, so you can make the road to bear the load and stress more uniform. In the project using Hongxiang new geotextile can also improve the rigidity of the road, help to reduce road cracks.

- Q:Engineering geotextile non-woven fabrics where the cheapest can buy, where the wholesale market?

- Manufacturers need to add 8720 -

- Q:Road with a geotextile cloth is a cloth or non-woven fabrics

- Geotextile is a non-woven category, geomembrane is divided into light film, and a cloth a film, two cloth a film, two cloth is a film in the middle of the membrane, both sides of the geotextile composite products. Huazhi geotextile material manufacturers

- Q:Are geotextiles resistant to punctures and tears?

- Yes, geotextiles are generally designed to be resistant to punctures and tears. They are made from strong materials that provide durability and can withstand external forces, making them an effective solution for various applications requiring such resistance.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Non Woven Geo Bag Used in Embankment Protection

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords