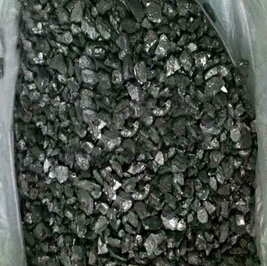

natural amorphous graphite recarburizer graphite crystalline particle

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t

- Supply Capability:

- 500000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Carbon Raiser:

Carbon raiser:

- F.C is 90-95% min

- 6-10mm,sulfur0.2% min

- Be made of Ningxia anthracite

- High absorptivity

Quick Details:

Place of Origin: Dalian China (Mainland) | Brand Name: ShengSa | Model Number: SSGCA |

Application: Foundry;Metallurgy | Dimensions: High-carbon | Chemical Composition: C ; S ; V ; ASH |

C Content (%): 93%min | S Content (%): 0.3%max | Ash Content (%): 6%max |

Vol . Matter: 1.5%max | Moisture content: 0.8%max | Size: as per customer's requirement |

Color: Black |

Packaging & Delivery:

Packaging Detail: | a.1 mt super bags. b.1 mt super bags on pallets. c.25kgs small bags on 1 mt super bags. d.25kgs small bags on 1 mt super bags on pallets. e.as per customers' requirement. |

Delivery Detail: | within 25 days against the down payment |

Gas Calcined Anthracite/GCA

Fixed carbon | 95%min |

Ash content | 4%max |

Vol . Matter | 1.2%max |

Sulphur content | 0.25%max |

Moisture content | 0.5%max |

Size | As per customers' requirement |

packing | 25kg paper bag on the pallet or 10kg paper bag shrieked wrapped on the pallet or 1MT big bag or other packing as required |

delivery time | 20days or depends on the order quantity |

Supply ability | 8000 Metric Ton/Metric Tons / Month |

Payment terms | L/C at sight or T/T |

Size: 1-4mm, 1-5mm, 3-8mm, 8-20mm (as per customers’ requirement)

Usage: Gas Calcined Anthracite/GCA is carbon raiser, widely used in steel-making, metallurgical

- Q:I heard that 85 of the furnace rock carbon harmony, and the result that I use advanced strengthening machine when I want to give high-grade furnace rock carbon, this how ah?

- DNF advanced method for obtaining carbon from furnace rock:DNF advanced furnace carbon can acquire rock at the mall, priced at 450 points and 50 points 10 coupon coupon 1.DNF advanced furnace rock carbon action:The use of advanced furnace rock carbon can start at the Kylie advanced equipment reinforcement machine, strengthening the probability of success is greater.Point Keri election advanced strengthening, plus ten or more equipment to strengthen, the probability is 10% more than ordinary furnace carbon

- Q:How is carbon used in the production of graphite?

- Carbon is used in the production of graphite by undergoing a process known as graphitization, where carbon atoms are arranged in a hexagonal lattice structure. This process involves heating carbon at high temperatures, causing the carbon atoms to align and form layers, resulting in the formation of graphite.

- Q:How dnf advanced carbon ashes?

- Before 70, strengthening with carbon, then the activities in the mall to sell high carbon, have to use coupons to buy, that is to improve the success rate of strengthening, now is also the time to rest, 80 edition, replaced by strengthening the body of the colorless, carbon was automatically replaced colorless (1: 5) senior carbon system did not automatically change on the left

- Q:How is carbon used in the production of textiles?

- Carbon is used in the production of textiles through various processes. For instance, carbon black, a form of carbon, is commonly used as a coloring agent in textile dyes, giving fabrics a wide range of colors. Additionally, carbon fiber, a lightweight and strong material derived from carbon, is used to create high-performance textiles for applications like aerospace, sports equipment, and automotive industries. Carbon-based chemicals are also used in textile manufacturing processes such as dyeing, finishing, and printing.

- Q:What are the consequences of increased carbon emissions on global trade?

- Global trade can be significantly affected by the increased carbon emissions. One immediate impact is the potential for countries and international agreements to impose stricter environmental regulations and carbon pricing mechanisms. This can result in higher costs for industries heavily reliant on carbon-intensive activities like manufacturing and transportation. Consequently, companies may experience increased production costs, which can be transferred to consumers through higher prices for goods and services. This can negatively impact global trade, as higher costs can reduce demand and hinder international competitiveness. Moreover, industries failing to comply with environmental regulations or carbon reduction targets may face trade barriers or sanctions, further limiting their participation in global trade. Another consequence of increased carbon emissions is the possibility of climate change-related disruptions to supply chains. Infrastructure can be damaged, transportation routes can be disrupted, and the availability and quality of resources can be affected due to rising temperatures, extreme weather events, and sea-level rise. This can cause delays in production and shipping, increased transportation costs, and a higher risk of interruptions in the supply chain. These disruptions can have far-reaching effects on global trade, impacting the flow of goods, services, and investments across borders. Additionally, increased carbon emissions contribute to global warming, which can have long-term implications for agricultural productivity and food security. Changes in temperature and precipitation patterns can result in crop failures, reduced yields, and shifts in agricultural production regions. This can disrupt global food supply chains, leading to price volatility and affecting trade flows. It may even exacerbate food shortages and inequalities. In conclusion, increased carbon emissions have multiple consequences for global trade. Stricter environmental regulations and carbon pricing can raise costs for industries, potentially reducing their competitiveness. Climate change-related disruptions to supply chains can cause delays, increased costs, and interruptions in trade. Furthermore, the impact of global warming on agricultural productivity can significantly affect food security and trade in agricultural commodities.

- Q:What are the carbon nanotube applications?

- The hydrogen storage materials: gas adsorption in adsorption is a solid adsorbent surface behavior the occurrence process of adsorbent and solid surface characteristics are closely related. The adsorption mechanism of nanoparticles, it was generally accepted that adsorption of carbon nanotubes is mainly due to the surface hydroxyl carbon nanotubes nanoparticles. The effect of carbon nanotubes on the surface of to hydroxyl and certain cationic bonding, so as to achieve the apparent of metal ions or organic matter adsorption. In addition, carbon nanotube particles have a large surface area, is also an important reason for the adsorption of carbon nanotubes. Zheng Qingrong, Gu Anzhong and [4] were studied on the adsorption behavior of hydrogen in carbon nanotubes Cheng Hui Ming et al. Synthesis of SWNTS treated properly can store hydrogen at room temperature, the hydrogen storage weight of up to 4.2%, and 78.3% of the hydrogen storage under normal temperature and pressure The hydrogen is released, and the remaining hydrogen is released after heating. The SWNTS can be reused and has a high commercial valueThe proton exchange membrane fuel cell (PEM) is a new type of carbon nanotubes: fuel cell vehicle power supply the most potential, the fuel cell through the consumption of hydrogen to generate electricity, the exhaust gas discharged into water vapor, therefore no pollution. It is compared with the lithium ion battery and Ni MH battery has great superiority. Can use carbon nanotubes hydrogen storage material supply hydrogen, can also be through the decomposition of oil and gas and other hydrocarbons or directly from the air to obtain hydrogen fuel cell hydrogen source.

- Q:How does carbon dating work?

- Carbon dating works by measuring the amount of radioactive carbon-14 isotopes in organic materials, such as bones or wood. As living organisms absorb carbon-14 from the atmosphere, they maintain a constant ratio of carbon-14 to carbon-12. However, once an organism dies, it no longer takes in carbon-14, and the existing carbon-14 begins to decay at a known rate. By comparing the remaining carbon-14 with the known decay rate, scientists can determine how long ago the organism died, providing a reliable method for dating organic materials up to about 50,000 years old.

- Q:What is carbon nanowire?

- Carbon nanowires, composed entirely of carbon atoms, are structures that exist in one dimension. They possess an incredibly thin nature, with diameters ranging from a few nanometers to a few micrometers, while their length can vary from a few micrometers to several centimeters. This exceptional thinness is due to their unique structure and composition, resulting in outstanding electrical, thermal, and mechanical properties. Various methods, such as chemical vapor deposition, electrospinning, or template synthesis, can be employed to produce carbon nanowires. They can exhibit different structures, including single-walled or multi-walled, and can be either straight or coiled. Additionally, the incorporation of other elements or functional groups into their structure can further enhance their properties. An important advantage of carbon nanowires is their remarkable electrical conductivity, which makes them suitable for a variety of electronic and energy applications. They can serve as interconnects in nanoscale devices, function as electrodes in energy storage devices like batteries and supercapacitors, and possess exceptional sensitivity for detecting various substances when used as sensors. Furthermore, carbon nanowires display exceptional mechanical properties, such as high tensile strength and flexibility. These characteristics enable their use in nanotechnology applications, including reinforcement in composite materials, as nanoscale actuators, or as templates for fabricating other nanoscale structures. In addition to their electrical and mechanical properties, carbon nanowires also possess excellent thermal conductivity. This makes them potential candidates for applications in thermal management, such as heat sinks or as fillers in thermal interface materials. In conclusion, carbon nanowires are thin carbon-based structures with outstanding electrical, thermal, and mechanical properties. Their unique characteristics make them highly promising materials for a wide range of applications in electronics, energy, sensing, nanotechnology, and thermal management.

- Q:What are the impacts of carbon emissions on wildlife?

- Wildlife and their ecosystems are significantly affected by carbon emissions, which have a profound impact on their survival. The release of greenhouse gases, primarily carbon dioxide, into the atmosphere is one of the main causes of climate change, which directly affects wildlife and their habitats. One of the most immediate consequences is the alteration of habitats. The rise in temperature can result in the loss of important habitats like coral reefs, mangroves, and polar ice caps, which are home to various species. This loss can lead to the displacement or extinction of vulnerable species, disrupting entire food chains and ecological systems. Additionally, climate change has a significant influence on the timing and availability of resources for wildlife. Changes in temperature and precipitation patterns can disrupt migration, breeding, and hibernation cycles for many species. This can create mismatches between the availability of food sources and the needs of wildlife, ultimately impacting their survival and ability to reproduce. Carbon emissions also cause ocean acidification, which is detrimental to marine organisms. When carbon dioxide dissolves in seawater, it forms carbonic acid, which lowers the pH of the oceans. This acidity negatively affects marine organisms, particularly those with calcium carbonate shells or skeletons, such as corals, oysters, and certain types of plankton. This disruption in the marine food chain can have cascading effects on other marine species, including fish, birds, and marine mammals. Furthermore, carbon emissions contribute to air pollution, directly harming wildlife. Pollutants like nitrogen dioxide and sulfur dioxide can damage respiratory systems, impairing the health and reproductive success of animals. This is especially harmful to species living in or near urban areas with high pollution levels. In conclusion, carbon emissions have extensive consequences for wildlife. Climate change disrupts habitats, alters resource availability, and contributes to ocean acidification. These changes can lead to the displacement or extinction of species, disrupt entire ecosystems, and jeopardize the health and survival of wildlife. It is crucial to reduce carbon emissions and implement sustainable practices to mitigate these impacts and conserve biodiversity.

- Q:What is carbon black filler?

- Carbon black filler is a type of material made from fine particles of carbon that is added to various products, such as rubber, plastics, and inks, to improve their strength, durability, and color.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

natural amorphous graphite recarburizer graphite crystalline particle

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t

- Supply Capability:

- 500000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords