Mild Steel Double T Equivalent to I Beam Steel in Middle Sizes

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Mild Steel Double T Equivalent to I Beam Description:

Mild steel double T equivalent to I beam is a beam with an I-shaped cross-section. The horizontal elements of the "I" are known as flanges, while the vertical element is termed the "web". Mild steel double T equivalent to I beam is usually made of structural steel and is used in construction and civil engineering. The mild steel double T equivalent to I beam resists shear forces, while the flanges resist most of the bending moment experienced by the beam. Mild steel double T equivalent to I beam theory shows that the I-shaped section is a very efficient form for carrying both bending and shears loads in the plane of the web.

2. Main Features of Steel I Beam Bar IPE Form:

• Grade: Q235

• Type: Mild carbon steel

• Deflection: The stiffness of the I-beam will be chosen to minimize deformation

• Vibration: The stiffness and mass are chosen to prevent unacceptable vibrations, particularly in settings sensitive to vibrations, such as offices and libraries.

• Local yield: Caused by concentrated loads, such as at the beam's point of support.

3. Steel I Beam Bar IPE Images:

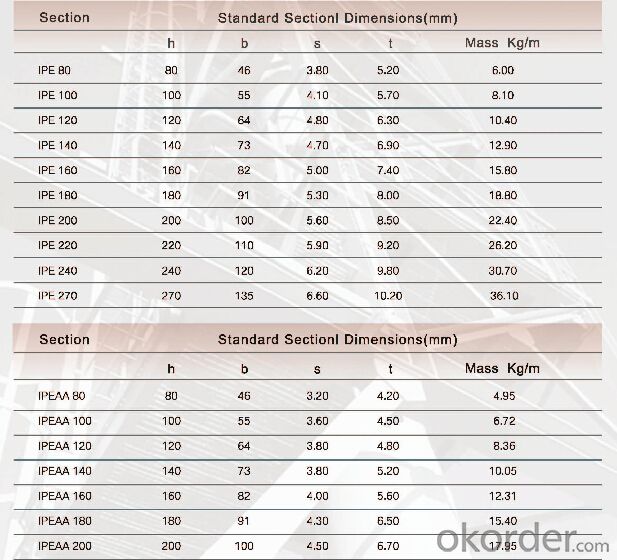

4. Steel I Beam Bar IPE Specification:

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①Is this product same as W beam?

In the United States, the most commonly mentioned I-beam is the wide-flange (W) shape. These beams have flanges in which the planes are nearly parallel. Other I-beams include American Standard (designated S) shapes, in which flange surfaces are not parallel, and H-piles (designated HP), which are typically used as pile foundations. Wide-flange shapes are available in grade ASTM A992,[4] which has generally replaced the older ASTM grades A572 and A36.

②How to inspect the quality?

We have a professional inspection group which belongs to our company. We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③Is there any advantage about this kind of product?

Steel I beam bar IPE has a reduced capacity in the transverse direction, and is also inefficient in carrying torsion, for which hollow structural sections are often preferred.

- Q:Can steel I-beams be used in overhead crane systems?

- Yes, steel I-beams can be used in overhead crane systems. In fact, they are commonly used due to their strength, durability, and ability to support heavy loads. Steel I-beams have high load-bearing capacities and are specifically designed to resist bending and twisting forces, making them ideal for supporting the weight of the crane and the loads it carries. Additionally, steel I-beams can be easily integrated into the structural framework of the crane system, providing a stable and secure support structure. Therefore, steel I-beams are a popular choice in the construction of overhead crane systems.

- Q:How do steel I-beams handle lateral loads?

- Steel I-beams are designed to handle lateral loads by their inherent structural shape and material properties. The shape of an I-beam, with its flanges and web, provides a high degree of resistance against lateral loads. The flanges, which are located on the top and bottom of the beam, are wider and thicker than the web, which is the vertical section connecting the flanges. This configuration allows the I-beam to distribute the lateral load across a larger surface area, effectively resisting bending and deformation. Moreover, steel, as a material, has excellent strength and stiffness properties, making it highly resistant to lateral loads. When subjected to a lateral force, the steel I-beam will resist deformation and maintain its shape due to the strength and rigidity of the material. To further enhance the ability of steel I-beams to handle lateral loads, additional measures can be taken. These include bracing the beams with diagonal or horizontal supports, which help to stabilize the structure and prevent excessive lateral movement. By incorporating these bracing elements, the overall lateral load resistance of the steel I-beam system is further increased. In summary, steel I-beams are well-suited to handle lateral loads due to their structural shape and material properties. The specific design of the I-beam, along with the strength and stiffness of steel, allows it to resist bending and deformation caused by lateral forces.

- Q:What is the difference between I-beam and H steel?

- The length of the I-beam is small and the height is big. It can only bear the force in one direction. H steel is deep in groove and big in thickness and can bear two directions of force.

- Q:What is the difference between the main keel and the angle steel and the channel steel?

- In addition to bearing, the keel also has a hydrodynamic role. The utility model enlarges the side area of the ship, improves the parallel impedance of the ship in water, and prevents the crosswind steering. This is especially important for sailing against the wind. In sailing, the keel is supported by a diagonal brace in the middle or at the base of the frame.

- Q:Are steel I-beams resistant to magnetic fields?

- Typically, magnetic fields don't have a high resistance against steel I-beams. Steel, being a ferromagnetic substance, possesses the ability to be magnetized to some degree. Nevertheless, steel's magnetism is relatively feeble in comparison to other ferromagnetic materials such as iron or nickel. Consequently, magnetic fields can exert an influence on steel I-beams, but the impact is generally negligible. Generally, the magnetic field would need to possess considerable strength to substantially affect the steel I-beams.

- Q:How about 5 tons of crane rail fixed on I-steel

- It is fixed on it with a special screw

- Q:Channel and I-beam are commonly used in construction sites. It is better to have on-site construction drawings, thank you

- Channel and I-beam are usually used to build floors.

- Q:How do steel I-beams resist bending and deflection?

- Steel I-beams resist bending and deflection through their specific shape and design. The I-shaped cross-section of the beam distributes the load evenly along its length, allowing it to effectively resist bending forces. Additionally, the high tensile strength of steel enables it to withstand these forces and prevent excessive deflection, ensuring structural stability and integrity.

- Q:How do steel I-beams perform in high-temperature bridge applications?

- Steel I-beams perform well in high-temperature bridge applications due to their inherent high strength and excellent fire resistance properties. The structural design of I-beams allows them to withstand substantial loads and provide stability in extreme conditions, including high temperatures. One of the main reasons steel I-beams are suitable for high-temperature bridge applications is their ability to maintain their structural integrity at elevated temperatures. Unlike other materials like wood or concrete, steel retains its strength and does not degrade significantly under high heat. This is crucial in bridge construction as it ensures the safety and reliability of the structure even in extreme conditions. Moreover, steel I-beams have a high melting point, making them resistant to heat-related deformations. This allows the bridge to maintain its shape and structural stability even when exposed to intense heat. Additionally, steel's low thermal expansion coefficient minimizes the risk of structural distortion caused by temperature fluctuations. In the event of a fire, steel I-beams also provide excellent fire resistance. Steel is non-combustible and does not contribute to the spread of fire, giving it an advantage over other materials. Furthermore, steel's high thermal conductivity helps dissipate heat quickly, preventing localized overheating and reducing the risk of structural failure. To enhance the performance of steel I-beams in high-temperature bridge applications, certain measures can be taken. For instance, the steel can be coated with fire-resistant materials, such as intumescent paint or fireproof insulation, to provide an additional layer of protection against high temperatures. Additionally, fire-resistant barriers can be incorporated into the bridge design to contain potential fires and limit their impact on the structure. In conclusion, steel I-beams are highly suitable for high-temperature bridge applications due to their inherent strength, fire resistance, and ability to withstand extreme conditions. Their structural integrity, resistance to heat-related deformations, and excellent fire resistance make them a reliable choice for constructing bridges that can withstand high temperatures and ensure the safety of the infrastructure and its users.

- Q:How do Steel I-Beams perform in terms of energy absorption?

- Steel I-beams are highly efficient in terms of energy absorption. Due to their structural composition and shape, they are capable of withstanding heavy loads and distributing the forces evenly along the beam. This allows them to absorb and dissipate energy effectively, making them a reliable choice for applications where energy absorption is crucial, such as in construction and industrial settings.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Mild Steel Double T Equivalent to I Beam Steel in Middle Sizes

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords