HR Steel Equal Beams with High Quality Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

1.Standards:GB,ASTM,BS,AISI,DIN,JIS

2.Length:6m,9m,12m

3.Material:GBQ235B,Q345BorEquivalent;ASTMA36;EN10025,S235JR,S355JR;JISG3192,SS400;SS540.

.

.

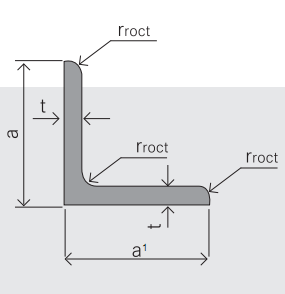

4.Sizes:

EQUAL ANGLES SIZES |

| ||

a(mm) | a1(mm) | thickness(mm) | length |

25 | 25 | 2.5---3.0 | 6M/12M |

30 | 30 | 2.5---4.0 | 6M/12M |

38 | 38 | 2.5 | 6M/12M |

38 | 38 | 3.0---5.0 | 6M/12M |

40 | 40 | 3.0---6.0 | 6M/12M |

50 | 50 | 3 | 6M/12M |

50 | 50 | 3.7---6.0 | 6M/9M/12M |

60 | 60 | 5.0---6.0 | 6M/9M/12M |

63 | 63 | 6.0---8.0 | 6M/9M/12M |

65 | 65 | 5.0---8.0 | 6M/9M/12M |

70 | 70 | 6.0---7.0 | 6M/9M/12M |

75 | 75 | 5.0---10.0 | 6M/9M/12M |

80 | 80 | 6.0---10.0 | 6M/9M/12M |

90 | 90 | 6.0---10.0 | 6M/9M/12M |

100 | 100 | 6.0---12.0 | 6M/9M/12M |

120 | 120 | 8.0-12.0 | 6M/9M/12M |

125 | 125 | 8.0---12.0 | 6M/9M/12M |

130 | 130 | 9.0-12.0 | 6M/9M/12M |

140 | 140 | 10.0-16.0 | 6M/9M/12M |

150 | 150 | 10---15 | 6M/9M/12M |

160 | 160 | 10---16 | 6M/9M/12M |

180 | 180 | 12---18 | 6M/9M/12M |

200 | 200 | 14---20 | 6M/9M/12M |

5. Material details:

Alloy No | Grade | Element (%) | |||||

C | Mn | S | P | Si | |||

|

|

|

|

|

|

| |

Q235 | B | 0.12—0.20 | 0.3—0.7 | ≤0.045 | ≤0.045 | ≤0.3 | |

|

|

|

|

|

|

| |

Alloy No | Grade | Yielding strength point( Mpa) | |||||

Thickness (mm) | |||||||

≤16 | >16--40 | >40--60 | >60--100 | ||||

≥ | |||||||

|

|

|

|

|

| ||

Q235 | B | 235 | 225 | 215 | 205 | ||

Alloy No | Grade | Tensile strength (Mpa) | Elongation after fracture (%) | ||||

Thickness (mm) | |||||||

| ≤16 | >16--40 | >40--60 | >60--100 | |||

≥ | |||||||

|

|

|

|

|

|

| |

Q235 | B | 375--500 | 26 | 25 | 24 | 23 | |

Usage & Applications:

Trusses;

Transmission towers;

Telecommunication towers;

Bracing for general structures;

Stiffeners in structural use.

Packaging & Delivery:

1. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

2. With bundles and load in 20 feet/40 feet container, or by bulk cargo, also we could do as customer's request.

3. Marks:

Color mark: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: There will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Images:

- Q:How do you calculate the load-bearing capacity of a steel I-beam?

- To calculate the load-bearing capacity of a steel I-beam, several factors need to be taken into consideration. Firstly, it is crucial to determine the properties of the specific I-beam being used. This includes knowing the dimensions of the beam such as the height, width, and thickness of the flanges and the web. These dimensions can usually be found in the manufacturer's specifications or can be measured directly. Next, it is necessary to determine the yield strength of the steel used in the I-beam. The yield strength is the maximum stress that the steel can handle before it begins to deform permanently. This value is typically provided by the manufacturer and is expressed in units of force per unit area, such as pounds per square inch (psi) or megapascals (MPa). Once the dimensions and material properties are known, the next step is to calculate the moment of inertia (I) of the I-beam. The moment of inertia is a measure of the beam's resistance to bending and is directly related to its load-bearing capacity. The larger the moment of inertia, the greater the beam's ability to withstand bending forces. The moment of inertia can be calculated using standard formulas based on the geometry of the I-beam. For example, for a symmetric I-beam, the moment of inertia can be calculated as (1/12) * b * h^3, where b is the width of the flange and h is the height of the web. Once the moment of inertia is determined, the load-bearing capacity can be calculated using the formula: Load-bearing capacity = (Yield strength * Moment of inertia) / (Section modulus * Safety factor) The section modulus is another property of the I-beam that measures its resistance to bending. It can be calculated as (1/6) * b * h^2, where b is the width of the flange and h is the height of the web. The safety factor represents a margin of safety and accounts for uncertainties in the calculations or unexpected variations in the load. Common safety factors for steel beams range from 1.5 to 3, depending on the specific application and building codes. By plugging in the values for the yield strength, moment of inertia, section modulus, and safety factor into the formula, the load-bearing capacity of the steel I-beam can be calculated. It is important to note that this calculation provides an estimate and should be verified by a structural engineer to ensure the structural integrity and safety of the building or structure.

- Q:What are the common connection methods used for steel I-beams?

- Various methods are commonly used to connect steel I-beams, including welding, bolting, and the utilization of steel plates. In the case of welding, it is a frequently employed technique for connecting steel I-beams. By applying heat to fuse the two steel pieces together, a durable and permanent bond is formed. Welding is favored due to its ability to create a continuous connection, ensuring the strength and stability of the structure. However, it necessitates skilled labor and specialized equipment for proper execution. Another popular method for connecting steel I-beams is bolting. This involves using bolts and nuts to securely fasten the beams together. Bolting offers the advantage of adjustability and easier disassembly if required. It also facilitates transportation and installation of the beams. However, bolting may not yield as strong of a connection as welding, and regular inspections and maintenance are necessary to ensure the bolts remain tight. The utilization of steel plates is an additional method for connecting steel I-beams. This entails adding steel plates to the flanges of the beams and bolting them together. Steel plates can be employed to connect beams end-to-end or side-by-side, providing versatility in different construction scenarios. This method offers commendable load-carrying capacity and is comparatively simple to install. However, it may necessitate more material and result in a bulkier connection compared to welding or bolting. Ultimately, the choice of connection method for steel I-beams depends on various factors, including load requirements, structural design, construction timeline, and budget. Each method has its own advantages and considerations. Therefore, it is crucial to seek guidance from structural engineers and professionals to determine the most suitable connection method for a specific project.

- Q:Can steel I-beams be used for mezzanines or elevated platforms?

- Yes, steel I-beams can definitely be used for mezzanines or elevated platforms. Steel I-beams are commonly used in construction due to their strength and durability. They can support heavy loads and provide a stable structure for creating additional floor space, such as mezzanines or elevated platforms. Steel I-beams are also versatile and can be easily customized to fit specific design requirements. Additionally, steel I-beams offer long-term reliability and require minimal maintenance, making them an ideal choice for constructing mezzanines or elevated platforms.

- Q:Can steel I-beams be used in the construction of schools and educational facilities?

- Yes, steel I-beams can definitely be used in the construction of schools and educational facilities. Steel is a strong and durable material that can provide structural stability and support to buildings. I-beams, specifically, are commonly used in construction due to their load-bearing capabilities, which make them suitable for supporting heavy loads and spanning long distances. Moreover, steel is fire-resistant and resistant to pests, making it a safe and reliable choice for educational buildings.

- Q:Can Steel I-Beams be used for educational institutions like schools or universities?

- Educational institutions like schools or universities can indeed utilize steel I-beams. Construction commonly employs steel I-beams due to their notable attributes of strength, durability, and versatility. They offer exceptional structural support, which renders them suitable for the construction of expansive and unencumbered areas such as classrooms, auditoriums, gymnasiums, and libraries. Moreover, steel I-beams can withstand substantial loads, ensuring stability and the safety of both the edifice and its occupants. Additionally, steel stands as an environmentally friendly choice for sustainability-conscious educational institutions, as it boasts a high recycling rate. In conclusion, steel I-beams serve as a dependable and pragmatic solution for erecting educational structures.

- Q:Can steel I-beams be used in the construction of parking structures?

- Steel I-beams are indeed applicable for the construction of parking structures. They are favored due to their robustness, longevity, and capability to bear substantial weights. These beams are specifically engineered to endure immense pressure and ensure structural steadiness, which makes them perfect for multi-level parking facilities. Furthermore, steel I-beams can be effortlessly manufactured and set up, enabling efficient construction procedures. Their adaptability also permits adaptable designs and arrangements that can accommodate diverse parking layouts and demands. In summary, steel I-beams are a dependable and economical choice for building parking structures.

- Q:What are the different types of steel I-beam connections for beam-to-beam joints?

- There are several different types of steel I-beam connections for beam-to-beam joints, including bolted connections, welded connections, and moment connections. Bolted connections involve using bolts and nuts to secure the beams together, while welded connections involve welding the beams together. Moment connections are designed to provide rotational flexibility to the joint, allowing for greater load-bearing capacity.

- Q:Can steel I-beams be used in high-rise buildings?

- Certainly, high-rise buildings can incorporate steel I-beams. In reality, steel I-beams are frequently utilized in the construction of high-rise buildings because of their robustness, longevity, and load-bearing capacities. The beam's I-shape offers exceptional structural support, enabling them to cover vast distances and bear substantial loads. Moreover, steel I-beams can be conveniently manufactured and assembled, making them a budget-friendly option for high-rise construction ventures. Their flexibility and capability to endure immense pressures and forces render them a favored choice for erecting the skeletal framework of high-rise buildings.

- Q:What are the advantages of using steel I-beams?

- There are numerous benefits to utilizing steel I-beams in construction endeavors. To begin with, steel I-beams are renowned for their exceptional strength and durability. They possess a remarkable load-carrying capacity, enabling them to bear heavy loads and endure extreme weather conditions. This renders them suitable for a diverse array of applications, encompassing bridges, buildings, and industrial structures. Moreover, steel I-beams afford design flexibility. They are available in various sizes and shapes, granting engineers and architects the ability to tailor them to the specific requirements of the project. This adaptability simplifies the creation of intricate structures and maximizes the utilization of space. Furthermore, steel I-beams exhibit fire resistance. Owing to their high melting point, they can withstand elevated temperatures more effectively than alternative materials such as wood or concrete. This attribute proves invaluable in terms of safety, as it affords additional time for evacuation and containment in the event of a fire. Additionally, steel I-beams necessitate minimal maintenance. Unlike wood, which is susceptible to rot or pests, steel is impervious to such issues. This translates into long-term cost savings, as regular repairs or replacements become unnecessary. Another advantage of steel I-beams lies in their eco-friendliness. Steel is an extremely recyclable substance, and the utilization of recycled steel in construction projects aids in diminishing the demand for new raw materials and reducing carbon emissions. Additionally, steel I-beams can be easily dismantled and repurposed in other projects, further contributing to sustainability efforts. Finally, steel I-beams confer excellent structural integrity. They possess consistent dimensions and properties, guaranteeing uniformity and dependability throughout the construction process. This renders them the preferred choice for engineers and builders who prioritize safety and stability. In conclusion, the utilization of steel I-beams in construction projects provides numerous advantages, including strength, design flexibility, fire resistance, low maintenance requirements, eco-friendliness, and structural integrity. These qualities establish steel I-beams as a reliable and efficient option for a wide range of construction endeavors.

- Q:Can steel I-beams be used for architectural facades?

- Yes, steel I-beams can be used for architectural facades. They are commonly used in modern architectural designs to create a sleek and industrial aesthetic. Steel I-beams offer structural stability and can be shaped and customized to fit various design requirements, making them a popular choice for architectural facades in commercial and residential buildings.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

HR Steel Equal Beams with High Quality Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords