Melt Extracted Stainless Steel Wire of Refractory Material

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: China

Model Number: 304,310,430,446

Material: Stainless Steel, Stainless Steel

Feature: High quality grade

Standard: ASTM A820

Types: Melt Extracted

Length: 25mm/35mm/19mm

Diameter: 0.3mm-0.7mm

Melting Point: Greater than 1500C

Application: Refractory Industry

Package: In cartons then put into pallets.

Production process:

Quality assurance:

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

FAQ:

Q: What kind of payments does your support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer.

Q: Do you have other products?

A: Yes, please check the pictures:

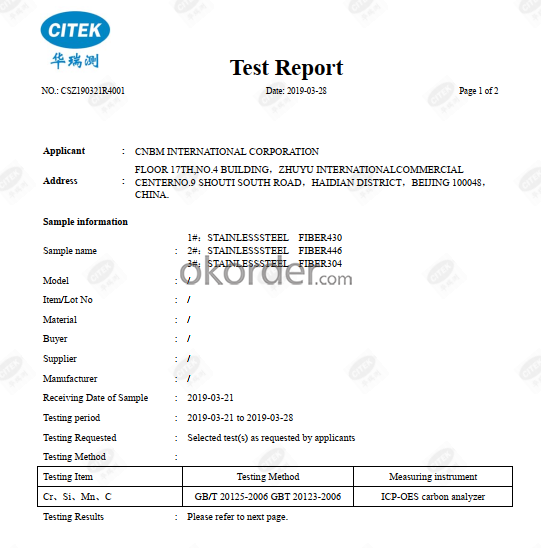

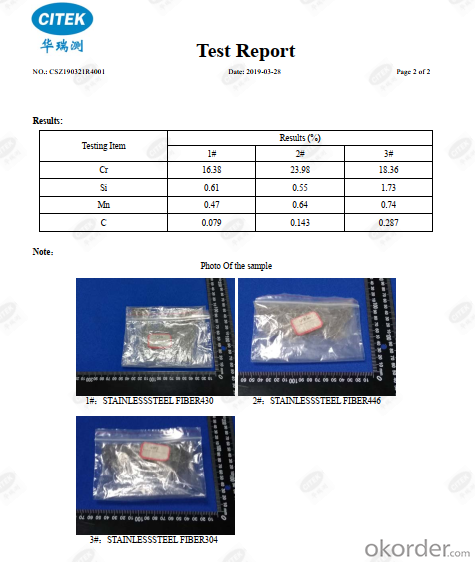

Test Report:

- Q:Who knows about roof fireproofing materials?

- Roof thermal insulation materials are various which generally can be divided into two categories, namely inorganic and organic materials: Inorganic materials are expanded perlite, aerated concrete, rock wool, glass wool, etc. Organic materials are styrofoam, polyurethane?foaming?plastic and so on. A. common roof thermal insulation materials 1. the expanding polystyrene board (EPS) has good thermal insulation performance, and cheap price but poor intensity with heat conductivity coefficient of 0.038-0.041. 2. extruded polystyrene board (XPS) has better thermal insulation performance and high intensity but an expensive price with heat conductivity coefficient of 0.028-0.03. It is moisture resistant but needs treatments on surface in construction. 3. rock wool board, with heat conductivity coefficient of 0.041-0.045, is fireproofing, fire?retardant. It has a good hygroscopicity performance but is poor in thermal insulation. 4. gelatine powder polyphenyl granule heat insulating slurry, with heat conductivity coefficient of 0.057- 0.06, has a good flame resistance performance, but the results of recycling and thermal insulation are unsatisfactory. It has high construction requirements. 5. polyurethane foaming material, with heat conductivity coefficient of 0.025-0.028, has good waterproofness and thermal insulation performance, as well as high intensity, but it is expensive. 6. perlite and other slurry, with heat conductivity coefficient of 0.07-0.09, have good flameproofness and water-absorbing ability but are poor in thermal insulation and thermostability.

- Q:Development trend of refractory industry

- In recent years, great changes have taken place in the world refractory industry. On the one hand, because of the improvement of technology and equipment and refractories own industrial users of technology progress, and refractory material consumption decreased year by year; in the past 20 years, the average annual consumption per ton of steel refractories decreased about 5 kg. The forecast for the next 5 years the average annual consumption per ton of refractory materials will drop to 0.5-1.0 kg range. The trend of globalization is obvious, and the competition is so fierce that the varieties of refractory materials are diversified, and the performance and quality are obviously improved. The service consciousness and ability of the refractory enterprises are strengthened for the users. Many lack of competitiveness, no modern enterprise management awareness of SMEs have been bankrupt, mergers and acquisitions surging. The production of refractories in developed countries is much higher than the cost of developing countries at the same time, due to more stringent environmental requirements, forcing them to produce only export high value-added products or technology, and bulk products, labor-intensive production shifted to developing countries. Because of its unique advantages of raw materials and labor cost advantages, there is no doubt that China will have more opportunities

- Q:Which fire-resistant materials have good viscidity?

- The viscidity of fire-resistant materials is also known as the binding performance of fire-resistant materials. It can be divided into chamotte and chemical binder. Both can work at normal or high temperature. The most commonly used chamotte are soft clay and aluminate cement. The commonly used chemical binders include sodium silicate, phosphoric acid, aluminum sulphate, aluminium phosphate, phenolic resin, etc. Fire resistant material is a complicated and overloaded system and we cannot know its materials and chemical components from the name alone. Both gunning mix and repair mix contain binder components. If they can used after adding water, then they may contain clay or fire resistan aluminum silicate cement.

- Q:How is grade of fire endurance divided?

- Fire resistance level is mainly decided according to the importance and function of the building. For example, very important buildings are set as the first level, and the less important is the second level, and so on.

- Q:What is the magnesium carbon refractory?

- The composition of refractory brick There are many types of raw materials of refractory brick, mainly divided into six categories: Soil, stone, sand, mineral, power and others. The first kind of raw material, soil: Aluminum soil, kaolin, clay, diatomaceous earth The second kind of raw material, Stone: Fluorite, kyanite, andalusite, forsterite, vermiculite, mullite, pyrophyllite, chlorite, dolomite, sillimanite, magnesia-alumina spinel, silica The third kind of raw material, sand: Pottery, zircon sand, quartz sand, magnesite The fourth kind of raw material, ore: Chrome ore The fifth kind of raw material, powder: Aluminum powder, silica powder, silicon powder The sixth kind of raw material of refractory brick, others: Asphalt, graphite, phenolic resins, perlite, cenosphere, sialon, corundum, silicon sulfate, silicon carbide, sodium silicate, silica solution, boron carbide, calcium aluminate cement, nitride material, shale ceramisite, alumina, alumina sol and zirconia, etc.

- Q:What refractories are accessible with ease in daily life?

- Basically there have all materials. But it depends on your needs.

- Q:What are the requirements on fire resistance period of C-level fireproof glass?

- What are the requirements on fire resistance period of Class C fireproof glass? The fireproof glass is a special glass which can maintain its integrity and insulation in required fire resistance tests, it can be classified into three types: Class A the fireproof glass which meet demands of fire integrity, and fire insulation at the same time. This glass has advantages of excellent transmittance, fire-proofing(smoke resistance, fire insulation, and blocking heat radiation), sound insulation and impact resistance. It can be applied to architectural ornaments, fire resistant timber doorsets with steel structure, windows, upper beam, partition walls, daylighting roofs, ceiling screens, perspective floor and other building components which need transparency and fireproofing. Class B: The fireproof glass which meets demands of fire integrity and thermal radiation intensity at the same time. This glass is mostly composite fireproof glass which has advantages of transmittance, fireproofing, and smoke resistance. Class C: The fireproof glass which only meets demand of fire integrity. This glass has advantages of transmittance, fireproofing, smoke resistance and high intensity. It can be applied to fireproof glass partition walls, fire windows and with no requirements on outdoor curtain walls, etc. The fireproof glass can be classified as composite fireproof glass and single chip fire-proof glass in terms of structure.

- Q:I wanna ask about the building insulation materials fire rating?

- the classfication of building insulation materials fire rating: 1. The thermal insulation material of level A combustion performance: Rock wool, glass wool, foam glass, foamed ceramics, foam cement, hole-closed perlite, etc. 2. combustion performance is level B1 insulation materials: Extruded polystyrene board (XPS) after special treatment / Special treatment of polyurethane (PU), phenolic aldehyde and gelatine powder polyphenyl granule 3, combustion performance is level B2 insulation material: Molded polystyrene board (EPS), extruded polystyrene board (XPS), polyurethane (PU), polyethylene (PE), etc.

- Q:hat kind of fire retardant materials are there

- There are many flame retardant plastics, which are modified on the basis of raw materials, such as flame-resistant ABS, flame-resistant HIPS, flame-resistant PP, flame-resistant PE, flame-resistant the PET, flame-resistant PBT, flame-resistant PC, flame-resistant PC/ABS alloy. Now there are mainly halogen flame retardant, though there are a lot of researches about halogen free flame retardant, the product stability and flame retardant effect remain to be improved. Testing methods of flame retardant materials are mainly: horizontal and vertical combustion, oxygen index method, NBS smoke box , thermal analysis, cone calorimeter, etc.

- Q:What's the organzational structure of refractory material?

- Ingredients (harmful); phase composition. The main components of refractory material include chemical composition and phase composition. The addtional components include main crystal phase, matrix, crystal phase, chemical composition

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Melt Extracted Stainless Steel Wire of Refractory Material

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords