Medium-frequency induction furnace 10Ton

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

The essence of the furnace is a kind of power supply device rectifying three-phase alternating current power to direct current

Medium frequency furnace

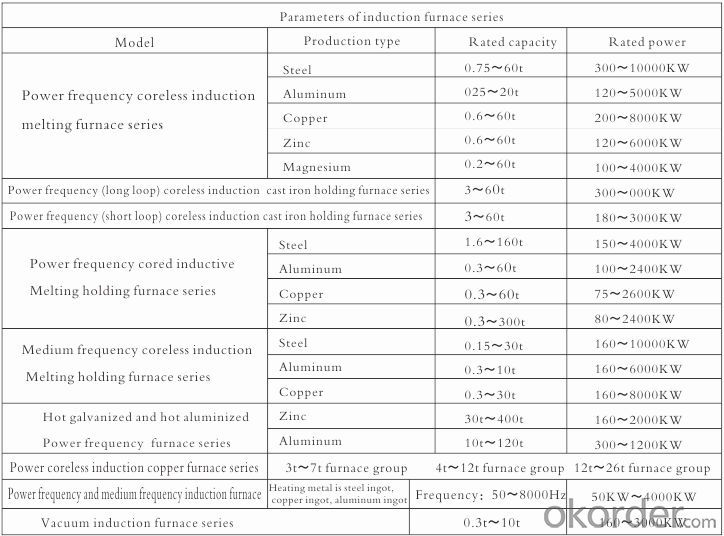

Product specification:

Medium-frequency induction furnace is the power supply device converting alternating current power to intermediate frequency power. The essence of the furnace is a kind of power supply device rectifying three-phase alternating current power to direct current and then changing direct current to adjustable current by inversion device to supply it to resonance circuit composed by capacitance and induction coil. Strong magnetic field is produced in induction coil, which makes metal material in induction coil produce big eddies. The resistance of metal itself can produce large amount of heat when large current passing. Therefore, metal material will become hot quickly.

Our company’s medium frequency induction furnace and power frequency induction furnace are widely used to smelting of non-ferrous metal ( It mainly is used in melting steel, alloy steel,special steel, cast steel and other ferrous materials, as well as the melting of stainless steel, copper, aluminum, zinc and other nonferrous materials. It can operate duplex with blast furnace.) It also widely used in forging heating and tempering heat treatment production line.

Features of medium melting furnace:

(1) The efficiency of melting is high, power-saving effect is good. The structure is compact. And the overload capacity is high.

(2) There is low temperature, few smoke dust and comfortable operating situation around furnace.

(3) Operation process is easy and smelting running is reliable.

(4) Metal components is well-distributed.

(5) Heat of melting is fast. Temperature of furnace is easy to control. Efficiency of production is high.

(6) The usage of furnace is high. And it is convenient to change types.

Features of medium diathermanous furnace:

(1) Fast speed of heating, high productive efficiency, low oxidation decarburization, saving materials and cost of forging dies

(2) Conductive working environment, improving the working condition and image of company, environmental protection and low energy consumption

(3)Evenly heating, extremely low temperature difference of table core, high precision temperature control

- Q:What is the difference between industrial furnaces and boilers?

- A boiler is a mechanical device for heating water into hot water or steam by the use of heat from fuel or other sources of energy. The original meaning of a pot is a water container heated by fire. The furnace is the place where the fuel is burned. The boiler includes two parts, the cooker and the furnace.

- Q:What is an industrial furnace pit?

- The creation and development of industrial kilns play an important role in the progress of mankind. Chinese appeared more perfect in the Shang Dynasty copper smelting furnace, furnace temperature is up to 1200 DEG C, up to 0.8 meters in diameter kiln stove.

- Q:Should the industrial furnace shell cool down?

- If the furnace shell temperature is too high, it shows that the lining is not good or damaged, so it should be repaired in time. If you do not repair, take the cooling way, undesirable. Because this will cause a lot of heat loss, resulting in waste of energy, increase production costs, and affect the service life of the furnace.

- Q:What is the difference between industrial furnace masonry and ordinary masonry?

- Industrial furnace masonry requirements are relatively high, industrial furnaces of different uses, whether material or masonry process, have strict requirements.

- Q:Heat treatment equipment (industrial furnace), which products generally contain what kind of, which industries need to use heat treatment industrial furnace equipment.

- Heat treatment furnace is mainly for the mechanical processing and casting industry workpiece annealing, quenching, carburizing, quenching and tempering, heat treatment equipment.

- Q:What are the advantages of a vacuum furnace?

- The utility model can completely eliminate the oxidation and decarburization of the workpiece surface in the heating process, and can obtain clean surfaces without deterioration layers. For cutting tools that grind only one side of grinding (such as twist grinding, the surface of the groove surface is exposed to the blade directly), the cutting performance is greatly improved.

- Q:What are the companies in the world that are currently engaged in metallurgical furnaces?

- Each manufacturer has its own industry and technological advantages.If you say that the performance rankings, turnover, and so on, it seems that no one has done this ranking.

- Q:What is industrial furnace masonry?

- Masonry industrial furnaces refers to complete materials such as brick kilns in construction process.

- Q:How many kinds of industrial electric furnaces are there?

- Industrial furnace according to the heating mode is divided into two categories: one is the fuel furnace, combustion heat with solid, liquid or gaseous fuel in the furnace for heating the workpiece; the second is in the furnace, the furnace converts electrical energy to heat the heat.

- Q:What is the difference in structure between industrial furnace and boiler?

- At the same time, the working environment is relatively poor, the structure should be sturdy and durable, the transfer mechanism (generally) to stable and durable low failure rate, the insulation layer must be thick enough and the economy, the steel structure housing materials used to be enough.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Medium-frequency induction furnace 10Ton

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords