Magnesia Alumina Spinel Brick with CE certificate for Fired Cement Kiln

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

| Place of Origin: | Shandong, China (Mainland) | Shape: | Brick | Material: | Alumina Block |

| SiO2 Content (%): | 50%~65% | Al2O3 Content (%): | 42% | Refractoriness (Degree): | Common (1580°< Refractoriness< 1770°) |

| Model Number: | SK34 | Brand Name: | CCEFIRE | Product name: | CNBM |

| Standard: | ASTM &JIS | Density: | 2.15-2.2g/cm3 | Fe content: | ≤2% |

| Standard Size: | 230*114*65/75mm | Porosity: | ≤26% | Refractoriness under Load (C): | ≥1300% |

| Refractoriness: | ≥1730C |

Packaging & Delivery

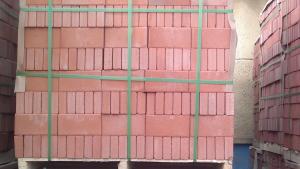

| Packaging Details: | Pallet or carton |

| Delivery Detail: | 7-15 working days after payment |

Product Description

MAKE FURNACE ENERGY EFFICIENCY SIMPLER

Fired Cement Kiln Magnesia Alumina Spinel Brick

refers to fire brick containing Al2O3 more than 48%, which is made of high grade bauxite through high temperature calcinations. It is is a kind of neutral refractory material so that it enjoys excellent resistance to acid and alkali corrosion. It has characteristic of high refractoriness under load, which decide high alumina brick is a n ideal material for various kinds of industrial furnace. It is widely used in building lining of hot-blast stove, blast furnace, coke oven, rotary kilns of cement and so on.

Name | CCEFIRE Fired Cement Kiln Magnesia Alumina Spinel Brick |

Size and Specifications | 230x114x65mm 230x114x75mm |

Type | High Alumina Brick |

Characteristics | 1 Excellent thermal stability 2 High refractoriness under load 3 Chemical stability and anti-corrision 4 Small high temperature creep rate 5 Excellent thermal shock resistance |

Typical Use | 1 Building materials for blast furnace 2 Building materials for hot-blast stove 3 Building materials for coke oven 4 Building materials for steel making furnace 5 For ladle 6 For construction material in steel industry |

- Q:What is the difference between corundum and high alumina?

- The main components of high alumina brick are high alumina bauxite, mullite and partial corundum sand.The difference between them lies in the content of alumina and the alumina refractory products with alumina content higher than 48%The content of Al2O3 is higher than 90%, which is called corundum brick.

- Q:What is the main component of corundum?

- The name of corundum originates from India and is the name of mineralogy. There are three main variants of corundum Al2O3, which are alpha -Al2O3, beta -Al2O3 and gamma -Al2O3 respectively. Corundum is second only to diamond.

- Q:Which is good, glazed brick and whole cast glazed brick?

- These two tiles have their respective advantages and disadvantages, in fact, to say which kind of good, mainly depends on the decoration of personal preferences and the location of the shop. If it is only the shop wall, then design and pattern rich whole glazed tile is good, it can make the room impressive, improve decorative effect, make the decoration style to fit the characteristics of his personality. In addition, clean up is relatively easy, not easy to contaminated with oil stains and other pollutants. If you are laying tile, suggested the use of tiles, tiles of good antiskid effect, water absorption rate is relatively low, so the kitchen toilet bathroom and other wet places is not easy to water seepage, improve the convenience of life.

- Q:How much is a refractory brick?

- This question is too general, refractory bricks according to the use of the environment and industry, there are a variety of materials, a variety of specifications, prices vary greatly.

- Q:What kind of refractory material will be used in the glass kiln?

- It has the best resistance to high temperature E glass corrosion, its erosion basically does not cause pollution to the glass liquid, so it has become the first choice of E glass unit refractory bricks.Dense chromium oxide is formed by isostatic pressing. Its density is very high. The main technical indexes include Cr2O3 content >94%, porosity <15%, volume density >4.24g/cm3, and erosion loss only 1/10 of compact zirconia brick. Used in the E glass furnace unit kiln, directly contact high temperature molten glass melt, wall, melting parts, high temperature parts, pool bottom, main channel, pool wall and pool bottom, transition channel, pool wall, etc..

- Q:What is the price of concrete self insulation bricks?

- If you really want to buy thermal insulation brick, do not simply look at the price, but also to consider the quality of the product. (a piece of brick in the market basically in 6 yuan, if there is a floating price if it is because of the size of the insulation brick or distance, but floating slightly.)

- Q:What problems should we pay attention to in the use of fused zirconia corundum brick (fused zirconia corundum brick) in glass furnace?

- Casting, casting mouth often appear shrinkage, brick porosity more, the density is lower, so in the brick wall of glass melting, the shrinkage in the kiln direction, if the nozzle outward, when the brick to erosion is very thin, can cause leakage of liquid glass accident. When the flame space is used in the upper part of the bath furnace, the service life is long, and the glass liquid problem can not happen, so the casting mouth is used outwards, and the service life is prolonged.

- Q:What equipment is used for producing diamond blanks? How much is the investment?

- Plus all the cables fifty thousand. Steel 10000 yuan. Corundum bricks; insulating bricks; clay bricks, these three require more than ten thousand. The electrode is about one hundred thousand. It's just an investment in an electric furnace. Together with the rear section processing and raw materials need hundreds of thousands of.

- Q:What refractory materials are used in industrial furnaces?

- Economically, it is necessary to do technical and economic analysis when selecting materials reasonably. Under the premise that the technical indexes agree with the working conditions of the furnace, the refractory materials with low quoted price should be used as much as possible, without high-grade finished products. To think about whether to make self (such as irrigation, refractory concrete) as far as possible to repair old.

- Q:How much is a thermal brick?

- Insulation brick prices also have a great relationship with the material and workmanship, such as clay brick price is much lower than high alumina brick, mullite and corundum brick prices will be higher.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Magnesia Alumina Spinel Brick with CE certificate for Fired Cement Kiln

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords