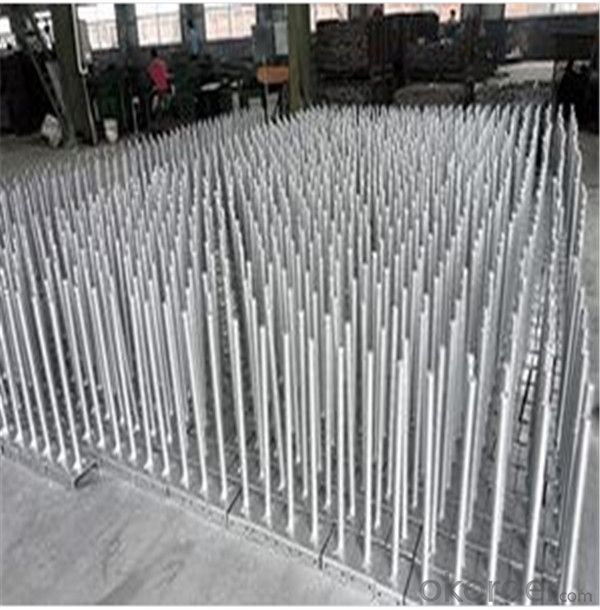

M38*4*600mm Hollow Screw Base Jack 150x150x5mm for Ringlock Scaffold CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of M38*4*600mm Hollow Screw Base Jack 150x150x5mm for Ringlock Scaffold

Material :Q235

Surface treatment :Painted, Electro Galvanized, Powder Painted, H.D.G

Size :M30, M32, M34, M36, M38, M48

Descriptions of M38*4*600mm Hollow Screw Base Jack 150x150x5mm for Ringlock Scaffold

Scaffold Adjustable Screw Jack with threaded bar and Cast nut, adjustable to 600mm, designed to fit inside a Standard / Vertical pole to support the load from a standard, and which, in conjunction with a thick baseplate, is used for levelling of Scaffold purpose.

FAQ

1. What is considerations of Scaffolding installation?

There must be a fire protection measures and specialist care, safety personnel patrol inspection when electricity, gas welding work on the scaffold,

(1) scaffold frontage hurtful to prevent falling objects protection is required.

(2) During take down the scaffolding, fencing and warning signs should be set up on the ground, prohibit others person besides the operator

2.What are the certifications of your products?

Certified by SGS, BS1139, EN74, Local Test Report.

3. How long is the warranty period for your product?

Our products warranty is 2 years.

- Q:Specification and type of scaffold erection

- 2 fasteners should be qualified factory, where brittle crack, deformation, sliding wire shall not be used. 3 steel scaffolding should be 2 ~ 3mm thick No. 3 steel plate, with the length of 1.4 ~ 3.6m, 23 ~ 25cm, width of rib height should be 5cm, available on both ends of connecting device, surface with anti slip hole, where the crack distortion may not be used.

- Q:Okay, quick question. I dropped into a couple of piercing studios yesterday to inquire about getting a scaffold done. Both places informed me that it's not a good idea to have it pierced with a bar straight off, as the pressure from the jewellery combined with the swelling when first pierced can seriously slow down the healing rate. Is this true? The second place said they will pierce both holes with rings, and these can be changed to a bar after around 6 to 8 weeks.Is this the best option? Thanks for any replies.

- That is true, but it's an even worse idea to have an industrial done with rings. This is because your body can move your piercings slightly, to accommodate the angle that works best for your body. In general, that's not a bad thing, but with industrials, it's a problem. You may find that an industrial healed with rings may not accommodate a bar well; the piercing may heal unaligned, and wearing a bar could be painful or impossible. Plus any shop that thinks changing from rings to a bar at 6 to 8 weeks will make any difference from getting a bar initially, you shouldn't trust to poke needles in you. Industrials take 6 months to a year or more to heal. At 8 weeks, the piercings are still very much healing. So if you have your jewelry switched at that point, you'll be irritating the piercing, setting back healing, and you'll have to deal with all of the pressure and hypertrophic scarring problems anyway. It basically comes down to this, industrials suck to heal. Bars are hard to heal. But rings will often result in bad industrial placement and alignment. Just get pierced with a bar and deal with the problems as they come. It's still very much possible to heal an industrial, it just takes time, patience, and a really good piercer (and like I said find a better shop, whoever told you it'd work to change the jewelry from rings to a bar at 8 weeks is an idiot).

- Q:by scaffolding ?

- It's a rhetorical question, maybe the girl is held up so well that it could have been something else holding her up there

- Q:scaffold, where to buy?

- northern tools . 1800-556-7885

- Q:Are the terms quot;nuclear matrixquot; and quot;nuclear scaffoldquot; interchangeable? I know that when we talk about DNA compaction we say that MARs on the DNA attach to the nuclear scaffold. I am wondering if the scaffold is just a specific part of the matrix??

- For most purposes, they are interchangeable terms for the same things. Some people favor one term, some the other. The ones who favor matrix over scaffold or vice versa may have some argument as to why it is better or a difference but in general people use them interchangeably.

- Q:Hi(: My names Tasha, and I love piercings. (I have 8) And I want to get an industrial piercing(Some call it a scaffold). But my ear doesn't have a bend like most people do.I got my first four piercings done by a professional. But felt I was much more comfortable having my brother(22) do it. Since he's someone I know, and hes done piercings and stuff before.

- This is why you need a pro. I can see where you should probably put a helix-to-helix industrial in that ear, but if yall can't see it, then I don't think you should be trying this, as neither of you have the experience a professional piercer does.

- Q:Construction, outdoor double scaffolding a square meter how many meters of steel pipe and how much?

- According to the height of their own construction plans, according to the construction area of 1 square root, fasteners ranging from docking fasteners and rotating fasteners, rotating fasteners should be every square of the 3 bar, a detailed look at the old construction workers

- Q:Can anyone give a very brief description on all three scaffold scenes in The Scarlet Letter?

- concentration your interest on who's on the scaffold, how they react to the regularly occurring public shaming, and what the reader learns with regard to the character from examining the define of them on the scaffold.

- Q:From the Scarlet Letter, Ch. 10-12

- Haven't read this book in years but I believe he goes back to the scaffold at night because he is being eaten away by guilt. It is a type of redemptive action, just as Hester had to stand there and be judged for her sins he feels the need to also stand there on the scaffold with Hester (theoretically) and be judged/punished as well, the only difference, of course, is that he does it under the cloak of night, when no one can see him.

- Q:Salt doesn't really make any different when cleaning infact I think it makes more dried skin to get stick on the bar. My side piercing is fine but the one closest to my eye is painful when pushed or touched I think this is because I accidentally sleep on it without realising. It's red but it has no lump around the piercing is it infected or is it just trying to heal?

- The reason why the earring will stick to the skin and dry up because you're using too much salt. Cleaning it with warm sea salt water is the best way to clean your piercing, especially soaking it in a bowl for 5-10 min. Make-up wipes have alcohol in them, which irritates piercings, just stick to salt. H2Ocean is great, it's a little pricey but it has the right salinity and other ingredients essential for healing tissues. It's not infected, it's just irritated because you slept on it. An infection will have pain, lots of swelling, dark yellowish pus, and throbbing. Give it a sea salt soak and the redness and soreness will go away.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

M38*4*600mm Hollow Screw Base Jack 150x150x5mm for Ringlock Scaffold CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords