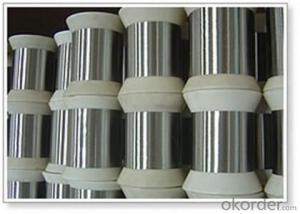

low carbon wire drawing machine manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100sets set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specifications

wire drawing machine

We continue R&D products and improve quality

our productsare confirmed by different buyers

|

| | |

| | | |

| | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

.

- Q:It is best to wash mechanical equipment using that cleaner

- It is recommended that the blue flying machine will be used for cleaning the surface of the equipment, cleaning the surface of the equipment and not damaging the paint on the surface of the equipment.

- Q:What are the types of cleaning equipment

- That is too much There are all kinds of homes, there are all kinds of business, and there are all kinds of special things

- Q:What is suitable for factory cleaning equipment

- Industrial vacuum cleaner is used to collect waste gas, dust and debris from equipment in industrial production, purify workshop environment, and no secondary pollution. High pressure cleaning machine, clean equipment oil pollution, rust stain, and some areas with small and unsanitary areas.

- Q:Where can I buy cleaning equipment

- Taobao, ali has a lot of, but the preparation factory actually is a few, the basic of taobao is the trafficker... If you haven't done it, try not to buy it, the depth of the device, it's too easy to get into a pit, find a physical store to practice, and see what they're using to buy the best

- Q:What is the pool cleaning equipment

- That should see you need to manually or automatic, manual cleaning equipment include: trolley, water pump, the suction sewage pipes, telescopic rod, suction pool head, pipe bend, and so on. Fully automatic is a complete set of facilities, which is ready to go directly to the water.

- Q:How do you clean the household central air conditioner

- It is mainly the filtration grid that is cleaning outlet, if can ask professional person to clean the wind channel is better

- Q:What are the sanitation facilities?

- Sanitation equipment including road cleaning equipment, trash pickup device, the landfill treatment equipment, now the fog haze weather serious mainstream sanitation develop haze reduction equipment manufacturer. And so on.

- Q:What is the cleaning equipment?

- The clean equipment industry has had the "hundred flowers and flowers" situation from scratch, and the quality of clean equipment and the quality and quality of the employees are uneven. Competition is in a state of disorder, the brand operation is chaos, a lack of continuity of effective promotion, users face the numerous brand dazzling, is difficult to choose to compare, the market and industry needs to be changed. The development of clean equipment will be the only way for the development of clean equipment to be made and managed by intensive, centralized resources.

- Q:Procter &gamble has some common cleaning equipment in the cleaning of the property

- Electric escalator cleaning machine: the clean and dry cleaning and drying of electric escalators are the best choice, easy to operate, multi-function and clean environment. Special design for escalators with different softness to choose from. Vacuuming, "water" as a filtration system, and equipped with a drain. The brush cover is equipped with special cleaner distributing device, easy to operate, easy to clean or change. Solve the problem of the traditional cleaning escalator.

- Q:The main parameters of ultrasonic cleaning equipment

- The main parameters of ultrasonic cleaning equipment are internal slot size, frequency, power and heating power.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

low carbon wire drawing machine manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100sets set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products