Stainless Steel Wire Drawing Machine manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

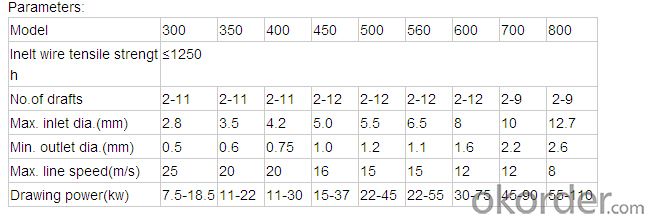

Specifications for Wire Drawing Machine

Straight Line Stainless Steel Wire Drawing Machine

1.electric parts adopt first-class brand at home and abroad.

2.PLC control.

Straight Line Stainless Steel Wire Drawing Machine

Description:

Straight Line stainless steel Wire Drawing Machine is mainly used for drawing various of metal wire from 6mm to 0.5mm , particularly suitable for drawing steel wire(high,medim,low carbon steel,stainless steel wire,prestressed wire,bead wire, rubber tube wire,spring steel wire,),welding wire(gas protection welding wire, submerged arc welding wire, flux-cored wire),alloy wire etc.

Technological process:

Pay-off---- Shell cleaning(pre-processing) ---- Wire rod pointing----(Buttering)----Drawing wire ---- Annealing ---- Take-up(spool or trunk take-up).

|

Main characteristics:

Reliability:Field bus technology was adopted to electrical control system,all digital control, electrical components are all international famous brand.Electrical control system is stable and reliable operation.

Energy saving: It adopts AC frequency regulator dragging which can reduce the impact of machine commission caused by motor start.

Security:It has multiple protection function, shield will open when the equipment high speed commission,or slow down to stop when meet other trouble.

High efficiency:It reduces the failure rate,average high working speed,greatly improve production efficiency.

Image for Wire Drawing Machine

|

| | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

.

- Q:How to keep the equipment clean

- The equipment needs to protect the electric motor circuit and the structure that need to adjust often is good! ~

- Q:It is best to wash mechanical equipment using that cleaner

- In addition to cleaning and cleaning, the mechanical cleaning agent must be in four defense: anti-corrosion, rust prevention, anti-pollution and fire prevention. Because of mechanical and electrical direct relation, inevitable result can cause spark to cause needless disaster! So you need to consider buying products that are volatile, undiluted, and gasoline

- Q:What are the types of cleaning equipment

- The question you ask is unscientific, and there is no way to answer it at all At least a small class

- Q:The heavy oil on the machine should use what cleaning agent to clean up?

- Kay's oil pollution cleaning agent A lot of machinery factory USES oil pollution cleaner now, the effect is very good,. ,,,,,,

- Q:What cleaning equipment does the factory clean equipment need?

- Lucky for you! I am also a factory and recently bought a lot of factory cleaning equipment. As far as I know, the cleaning equipment of the factory can be divided into cleaning equipment and cleaning equipment. Our factory in shenzhen buji there was the last time a company called jie I now, is dedicated to sell industrial cleaning equipment company to buy the machine, the staff attitude is very good, also very professional! Ask for advice if you need it

- Q:What is the pool cleaning equipment

- Disinfection system (water treatment of swimming pool is very important, the water quality is not up to the standard to affect the opening) : Metering pump Drug delivery; Ozone generator. Lighting system (underwater lamp beautification swimming pool) : Pool wall lamp; Waterproof cable. Fully automatic thermostat (the temperature of the water in the swimming pool) : Fully automatic heating furnace; Water and water heat exchanger (commonly known as plate change); Temperature controller; Electric valve. Cleaning equipment (pool brush, leaf net, telescopic rod, suction head, wire brush). 5, the pool bank facility (escalator, departure stage). Water quality monitoring equipment (water quality monitor, test water box, water temperature meter). Water treatment pipe fittings.

- Q:What are the sanitation facilities?

- There are many kinds of clean sanitation equipment, general sanitation cleaning equipment to sweep the floor clean, high pressure cleaning is given priority to, the driving type is sweeping machine was used to replace the manual cleaning equipment, high pressure cleaning machine can finish the stubborn stains such as the ground oil clean.

- Q:The oil can be cleaned by the tank cleaning and the cleaning of the tank is the cleaning of the machine

- The tank cleaning industry at present, the general take artificial cleaning, mechanical equipment cleaning tank is just rise recently, really can do mechanical cleaning also does not have a few, and some manufacturers are generally abroad, prices more expensive each device also need to around 10 million, as currently on the market what the robot cleaning tank while the price is cheaper, but the technology is relatively insecure, we cleaning company is this year just at the beginning of the year on a mechanical cleaning equipment, the effect is good, the key is cheap compact result, oil recovery rate can reach 90%, in the process of cleaning is content value.

- Q:How often do the reverse osmosis of pure water equipment wash the search?

- Generally, under the condition of normal operation, reverse osmosis membrane may also be inorganic scale, colloid, microorganism, metal oxides, such as pollution, these substances deposited on the membrane surface to cause water purification equipment, reverse osmosis device output descent or desalination rate, differential pressure increases, and even cause unrecoverable damage to membrane, therefore, in order to restore good waterproof and desalination performance, need for chemical cleaning membrane.

- Q:Clean the cleaning parameters of the equipment

- The main still should see you clean thing, clean the rough, no strict requirements to surface with low frequency is ok, but for some mesh class cleaning high frequency, it is best to this can reduce the workpiece of ultrasonic cavitation effect. Secondly depends on the choice of cleaning medium, weak alkaline medium SUS304 steel can, weak acid or not enough, easy to form in acoustic surface acidification, steel easy ageing.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stainless Steel Wire Drawing Machine manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords