Clean Room Cotton Swabs ST-004 CA-003

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

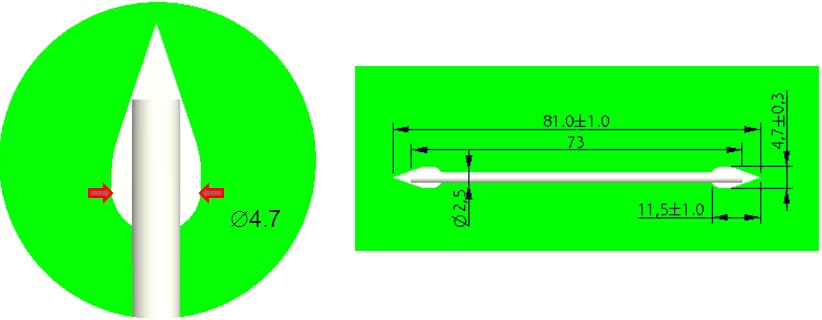

Product No.:ST-004 (CA-003)

Stick:3” Paper

Stick Diameter:2.5mmØ

Tip Diameter:4.7+/-0.3mm

Tip Length:11.5+/-1.0mm

Total Length:81.0+/-1.0mm

Packing Way:25pcs*100packs*10boxes

Carton Size:55*52*22cm

The clean room cotton buds are widely used in cleaning precise electronic components, laser, semi-conductor, optics lens, and magnetic read head etc. Our clean room cotton swabs can dip with DI Water, alcohol, IPA, and acetone solution. ST-004 is the perfect replacement of CA-003 in HUBY340 series.

- Q:It is best to wash mechanical equipment using that cleaner

- See what equipment needs to be cleaned, the current cleaning agent is nutritionally ionized, non-ionized... Principle: 1. The cleaning agent shall not be related to damage, corrosion and pollution. Effectively remove dirt; You can satisfy these two principles

- Q:What are the types of cleaning equipment

- That is too much There are all kinds of homes, there are all kinds of business, and there are all kinds of special things

- Q:The heavy oil on the machine should use what cleaning agent to clean up?

- Kay's oil pollution cleaning agent A lot of machinery factory USES oil pollution cleaner now, the effect is very good,. ,,,,,,

- Q:What is the issue of cleaning equipment? Is there a difference between industrial cleaning equipment and common equipment?

- Industrial high pressure cleaning machine: product positioning is machine equipment Industrial high pressure cleaner is designed according to the condition of industrial cleaning, generally USES a relatively low speed, forged steel crankshaft crankshaft, crosshead bearing alloy, independent lubrication system and electrical control cabinet. The main characteristics are: high reliability, high load capacity, high safety factor. The materials used in machine manufacturing are quite elegant, including manufacturing accuracy, heat treatment of materials, testing and strength tests. The highest rated working pressure of the industrial high pressure cleaning machine is much higher than the highest rated working pressure of the commercial high pressure cleaning machine. 2: under the same technical parameters (pressure flow), industrial high pressure cleaner can effectively continuously working time is more than commercial grade high pressure cleaner can effective working hours continuously.

- Q:How many kinds of cleaning equipment are there for cleaning companies?

- Ogilvy Lin cleaning cleaning tool use commonly: 2000 w vacuum suction machine, multi-function cleaning machine, polishing machine, glass scraper, with water, glass cutter, clean ball, microfiber cloth, towel (one-time), glass cleaner, clean neutral detergent, highly-effective cleaning agent, speed powder, seat belts, telescopic rod, brush, herringbone ladder, toolbox, rubber gloves and other professional tool

- Q:How do you clean the household central air conditioner

- Household central air conditioning main cleaning filter and the house of the dirt on the condenser fin, under normal circumstances can filter down to water boiling, outdoor hoses washed clean. As for the internal cleaning of the refrigeration system, it is usually not necessary to clean the system as long as it is cleaned.

- Q:What is the cleaning equipment?

- Cleaning equipment categories: push car wash machine to wash to wash his hands to machine driving type cleaning machine automatic car washing machine to clean the floor sweeping machine hand push sweeping machine driving type of the machine Automatic sweeping machine industrial vacuum cleaners, etc.

- Q:Procter &gamble has some common cleaning equipment in the cleaning of the property

- Electric escalator cleaning machine: the clean and dry cleaning and drying of electric escalators are the best choice, easy to operate, multi-function and clean environment. Special design for escalators with different softness to choose from. Vacuuming, "water" as a filtration system, and equipped with a drain. The brush cover is equipped with special cleaner distributing device, easy to operate, easy to clean or change. Solve the problem of the traditional cleaning escalator.

- Q:The oil can be cleaned by the tank cleaning and the cleaning of the tank is the cleaning of the machine

- It's usually a person + device approach

- Q:The main parameters of ultrasonic cleaning equipment

- The main parameters of ultrasonic cleaning equipment are internal slot size, frequency, power and heating power.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Clean Room Cotton Swabs ST-004 CA-003

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords