SS wire 0.13mm,410 ,430 ,GI wire for kitchen scourers

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100Tons m.t/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specifications

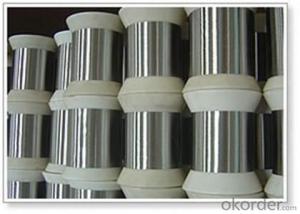

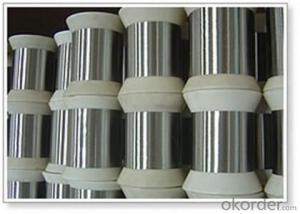

cleaning ball wire

1.material:SS410 SS430

2.wire diameter: 0.12mm-0.23mm

3.spool weight:2kg/spool-15kg/spool

Chemical composition of stainless steel wire:

AISI Grade | Chemical Composition(%) | |||||||

C | Si | Mn | P | S | Ni | Cr | Mo | |

| 304 | =<0.08 | =<1.00 | =<2.00 | =<0.045 | =<0.030 | 8.00~10.50 | 18.00~20.00 | - |

| 304H | >0.08 | =<1.00 | =<2.00 | =<0.045 | =<0.030 | 8.00~10.50 | 18.00~20.00 | - |

| 304L | =<0.030 | =<1.00 | =<2.00 | =<0.045 | =<0.030 | 9.00~13.50 | 18.00~20.00 | - |

| 316 | =<0.045 | =<1.00 | =<2.00 | =<0.045 | =<0.030 | 10.00~14.00 | 10.00~18.00 | 2.00~3.00 |

| 316L | =<0.030 | =<1.00 | =<2.00 | =<0.045 | =<0.030 | 12.00~15.00 | 16.00~18.00 | 2.00~3.00 |

| 430 | =<0.12 | =<0.75 | =<1.00 | =<0.040 | =<0.030 | =<0.60 | 16.00~18.00 | - |

| 430A | =<0.06 | =<0.50 | =<0.50 | =<0.030 | =<0.50 | =<0.25 | 14.00~17.00 | - |

7. The Pic for the stainless steel wire

- Q:The equipment of our unit needs to be cleaned regularly, oil pollution is very much, every time manual washing efficiency is too low, what method can be solved quickly?

- Look at that oil and then choose the emulsifier To use the all-around emulsifier for oil and other oil Used for lubricating oil, mechanical oil and mine Oil, clutch oil, gear oil, brake oil, engine oil, ink, demoulding oil, compressor oil, refrigeration oil, vacuum pump oil, the internal combustion engine oil (1: diesel engine oil. 2: gasoline engine oil. 3: ship oil), oil bearing, guide Rail oil, hydraulic oil, hydraulic oil, metal processing oil dynamic tools, electrical insulating oil, oil, heat conduction oil, rust-proof oil, special occasions, oil, turbine oil, quenching oil, fuel oil, oil have oil selection and other occasions Engine oil emulsifier, no oil emulsifier is the domestic initiative of non-toxic + environmental protection + high efficiency emulsifier. For the removal of oil emulsifier and oil emulsifier, nano-oil emulsifier is used for the removal of oil and oil emulsifier in addition to oil and inorganic oil

- Q:How to keep the equipment clean

- If you don't use this device, he'll always be clean

- Q:How do you clean the inside of the electric oven? Can you use a wire ball or a detergent?

- Remember a TV show that USES a bowl of lemon water cloth cover, ten minutes of evaporation and then a soft cloth to wipe it off without a chemical smell.

- Q:What are the types of cleaning equipment

- The question you ask is unscientific, and there is no way to answer it at all At least a small class

- Q:Article 84 in GMP, the production equipment shall be cleaned according to the operating procedures specified in detail. Production equipment cleaning procedures shall stipulate detailed and complete cleaning methods, cleaning with the name of the equipment or tools, cleaning agents and preparation method, to remove the previous batch identification methods, protect already clean equipment before use from pollution methods, already clean equipment for the longest time limit, preserved...

- This time is dirty time, oneself according to the production requirements for 3 days, 3 days after completing equipment use clean, if qualified, cleaning validation then SOP can regulation equipment should be used in within 3 days from the end of the cleaning.

- Q:Characteristics of cleaning equipment of cleaning equipment

- High pressure water jet cleaning mainly has the following characteristics: (1) selecting the appropriate pressure level, the water jet cleaning will not damage the base of the cleaning equipment. (2) is using ordinary tap water with a high speed washed clean, so it does not pollute the environment, anti-corrosion equipment, won't cause any mechanical damage, can also be removed with chemical cleaning of refractory or cannot dissolve the special scale; (3) after washing, the equipment and parts shall not be cleaned; (4) cleaning parts that are complex in shape and structure, which can be cleaned in a space narrow, complex, hostile and harmful environment; (5) it is easy to achieve mechanization, automation and digital control. (6) save energy, clean efficiency and low cost. Chengdu feng cleaning machine, with its strong technical force and reliable after-sales service protection, the pressure washer in the domestic many areas have a large promotion, cleaning machines are exported to overseas markets, done a good job in the technology field.

- Q:What are the cleaning facilities for the hotel?

- There are plenty, such as a hotel lobby or a bedroom with a floor cleaner and some cleaning tools and other products for reference only

- Q:What is the pool cleaning equipment

- TR - 300 pool cleaning machine (the queen) : by motor sediment and suspended solids in the suction machine, the water through the filter to filter inside the machine, put the clean water, so as to achieve the cleaning effect. Hd5/11c water gun: applied to the outside of the building, the outside of the building, the external gun, the garage, the floor of the workshop, the kitchen, the vehicle, the pool cleaning, etc.

- Q:The oil can be cleaned by the tank cleaning and the cleaning of the tank is the cleaning of the machine

- There are a lot of mechanical cleaning equipment in storage tanks, and the cleaning process is different, and the cleaning effect is different.

- Q:Clean the cleaning parameters of the equipment

- Judge a ultrasonic cleaning machine general technical indicators as to stay ageing degree and resonant, impedance and impedance matching are already debugged before they go out, the key lies in you to do. Of course, the sound of ultrasonic cleaning machine and generator is now being silenced. The bonding mode of the oscillator is usually made of special cement, and the bolt fastening effect is good, but it is not suitable for maintenance. Frequency selection is cleaned according to the workpiece to decide, general material or on the surface is not very high, with 28 KHZ, more strict for cleaning, or had better choose high precision parts. This is because, the lower the frequency of the bubbles, the greater the when ultrasonic frequency is greater than 800 KHZ, there is no cavitation bubbles, this to be the effect of cleaning the surface of the cavitation corrosion is the lowest. In addition, the ultrasonic cleaning is the effect of the high pressure produced by an empty bubble in the instantaneous blast.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

SS wire 0.13mm,410 ,430 ,GI wire for kitchen scourers

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100Tons m.t/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords