Lightweight concrete wall panel forming machine HQJ150-600

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

HQJ150-600 Lightweight concrete wall panel forming machine

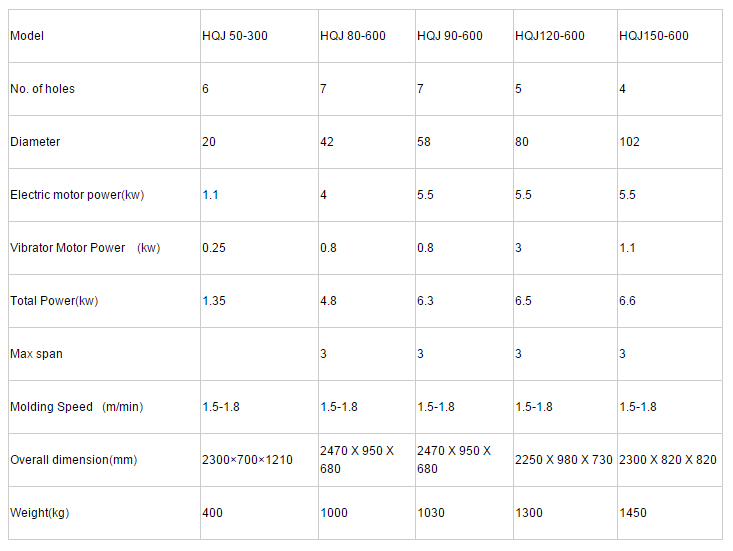

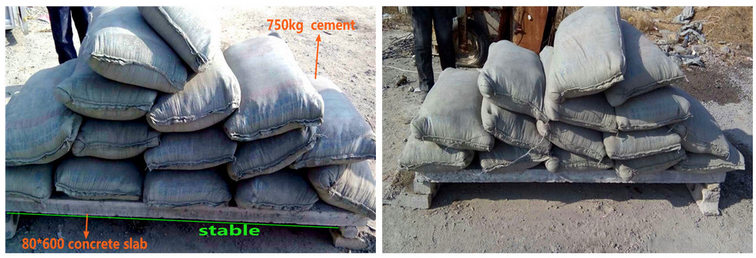

Quick Details

· Condition: New

· Application: prefab building

· Automatic Grade: Automatic

· Production Capacity: 60-70m/h

· Place of Origin: Shandong, China (Mainland)

· Brand Name: LING FENG

· Model Number: SL80*600

· Voltage: 360v

· Power(W): 4.5-8.0kw

· Dimension(L*W*H): 2.5*1.0*1.0m

· Weight: 2.0T

· Features: high efficiency

· Certification: ISO9001/CE

· Warranty: 12 months

· After-sales Service Provided: Engineers available to service machinery overseas

· Main frame: 2.0*1.4m

· Color steel thickness: 0.3-0.8 mm

· Insulation: first class

· Shaft axis: diameter 80

· Brick Raw Material: Cement, sand, stone.

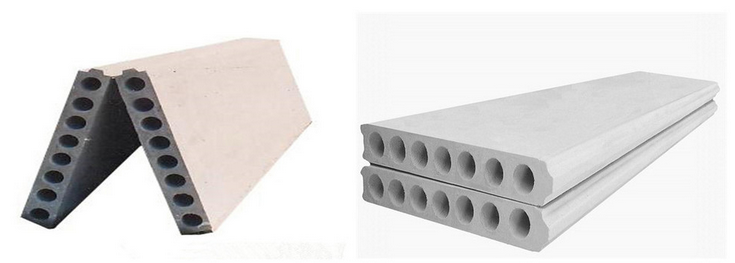

· Strength: water proof, fireproof, sound proof

· Vibrator type: ZW type 3.0kw

· Motor model: YEZ132S-4-B5

· Color: yellow or custom

· OEM: available

Products

Quality

Packaging & Delivery

Packaging Details: Wooden case and wood flour into the bottom of the box.

Delivery Detail: Within 15 days

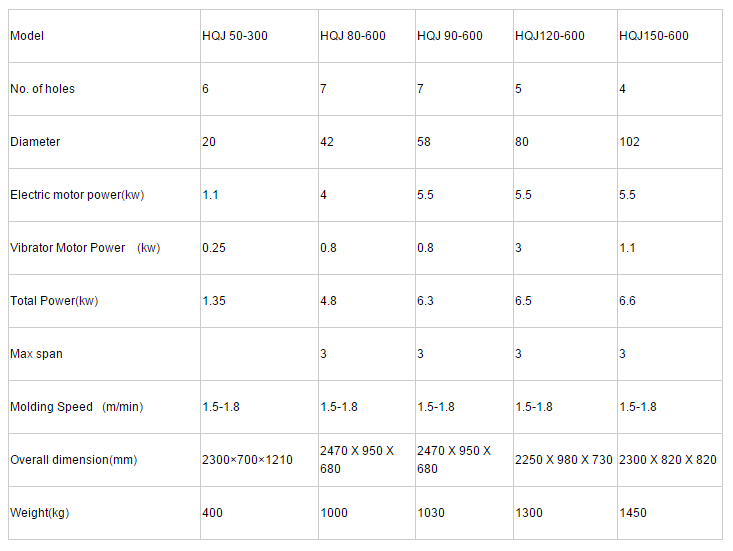

Major Parts and advantage of lightweight wall panel machine

Features:

I. Anti-corrosion and wear-resistant.

The machine frame is made of manganese steel whose quality is better than normal steel. The interior side of the mould is made of stainless steel (its thickness can be 2.2mm) which can stand repeated use and corrosive materials. It can be used for over 10 years. Besides, panels made by this kind of machine have better quality than other kinds. The panel will not be deformed. Its surface is smoother than others.

II. High capacity

Normal hollow core wall panel machine can make only ten panels in one mould, but this machine can make 14 panels at one time.

III. Energy-saving

The machine uses storage battery as power which can save a lot of electricity and is safe to use. Besides, if there is something wrong with the machine in the production line, it will not influence the use of other machines.

IV. Lower the cost of production

We use stainless steel for the mould instead of traditional steel. Steel mould machines need brushing de-molding agent or the panels can't be taken out. Stainless steel machines need a little de-molding agent, this can save both labor and material cost for manufacturers.

V. Hydraulic mould closing and opening

The mould is opened and closed by hydraulic. Its moving is very smooth and stable. All the four sides of the mould can be opened together, so it is very easy to use and it can save labor and cost.

VI. Unique design

We have special design not only for the single machine, but also for the whole production line. Our mixer can be customized for the customer according to their requirement. We also have special equipment to get rid of the dust so that the production is very clean.

Our Services

Interests in the good faith, interests in quality, interests in the service

Customer visits and technical guidance provides 24-hour service and lifetime maintenance services, supply of spare parts. Site church consumer operation, teach operating essentials, equipment maintenance and production experience, considerations.

Our factory can produce all kinds of equipment and prefabricated factory accessories according to customer demand.

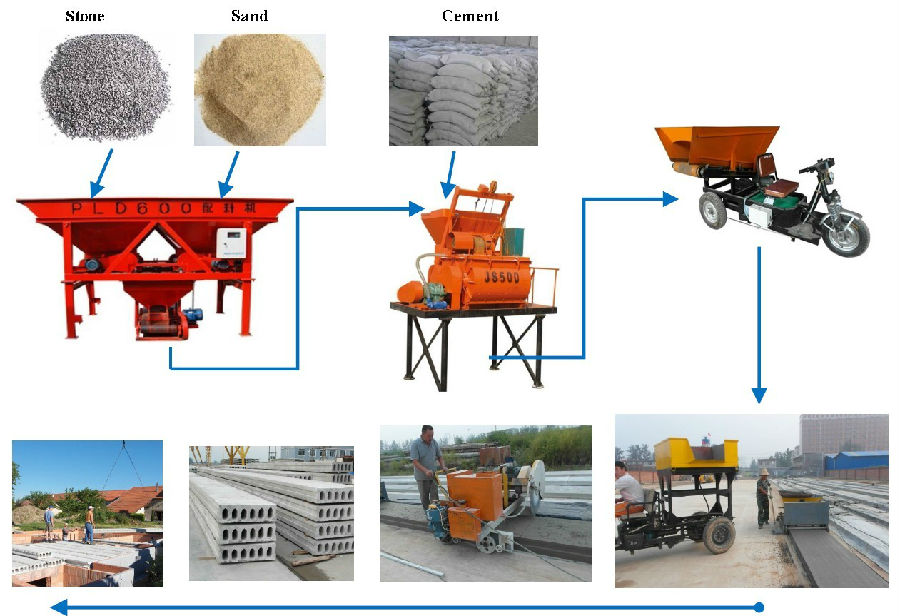

Flow chart:

Other available machines:

- Q:The DNA replication machinery is assembled at the replication fork. A. True B False

- False, its not assmbled at the replication fork

- Q:the metalic variety

- I would have to see it to tell you but stamping,casting or machining are the most common.

- Q:It's subject is World World I and the Roaring 20's.

- Automation is I believe the term you're looking for. Though I don't know how to relate it to WW1 and the post-war period.

- Q:Does anyone know what this piece of machinery is/does?

- Looks like a fence tightener to me. The pulley with the chain stops is the working pulley and the cable pulley is the tightener. Just pull on the chain and the cable is pulled at the same rate, thereby tightening the cable on the fence. Just a guess though.

- Q:Which is better, motor or diesel, on construction machinery?

- To see the condition of the site, usually using a motor on the scene of the air environment is good, and the use of construction machinery motor will require electrical lines and other equipment, equipment cycle longer, but a long time will benefit. Diesel driven construction machinery is more flexible, for a number of short-term changes in the operation of great benefits.

- Q:what are the machinery needed to produce many corndogs, corncerning the storage and process of ingredients?

- This is a patent. An apparatus for preparing and cooking corn dogs (batter-coated wieners on a stick) which has a receiving bin, a loading apparatus, and a collecting and aligning system for arranging the wieners to receive sticks that form a handle for the finished product. The sticks are inserted into the wieners, and the stick impaled wieners are moved through a coating bin where batter is applied. They then progress to a fry tank containing hot grease where they are cooked. Preliminary heaters are positioned near the loading device and the collection and aligning system to bring the temperatures of the wieners up to around 80° Fahrenheit prior to insertion of the sticks, application of the batter, and introduction to the fryer. The method for utilizing the apparatus is included and enables the product to achieve faster cooking times and higher production by applying heat at at least two locations to the wieners as they move toward the fry tank for cooking.

- Q:Privacy statement of used construction machinery network

- If you do not agree to be modified content, users can take the initiative to cancel the network services have been obtained. If the user continues to enjoy the Internet service, it is accepted as a change in privacy policy. It is recommended that users regularly consult.

- Q:Machinery has its tools that need to be replaced after 10 years for technical reasons. At the balance sheet, the tools have been in use for 5 years.Explain is there any present obligation and whether provision is recognized or not?If yes then why?

- Question of Inventory precaution.

- Q:Britain has an unwritten constitution.Then how does the political machinery work over here?

- The government makes policies telling us what to do, without our consent, then they monitor us all to make sure we're complying. If we don't comply with even the smallest rule, they fine or jail us, while paedopiles and rapists get through the criminal justice system with a slap on the wrist. The political system over here is glossy, sleezy and every political party is the same, so we have no choice. Or am I just being cynical?

- Q:I'm thinking about making something out of wood but I dont have any machinery to do it, all I have Is a saw and a couple knives but that's it. Any ideas?

- you can make plenty of stuff WITH GOOD PLANS ..... what you need is to determine the project and what wood and the cuts to do your project === take your plans to Lowe's or the HoDepot and buy the wood and get then to cut the wood to your specs [[[ sma

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Lightweight concrete wall panel forming machine HQJ150-600

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords