Lightweight concrete wall panel forming machine HQJ 50-300

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

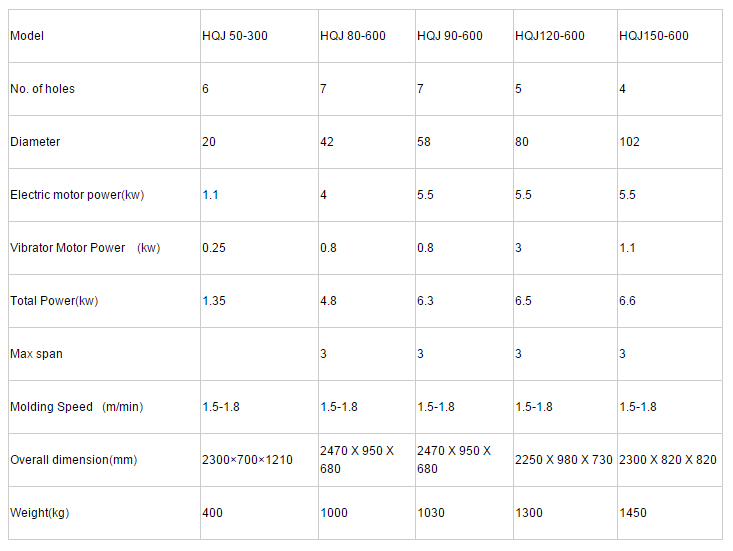

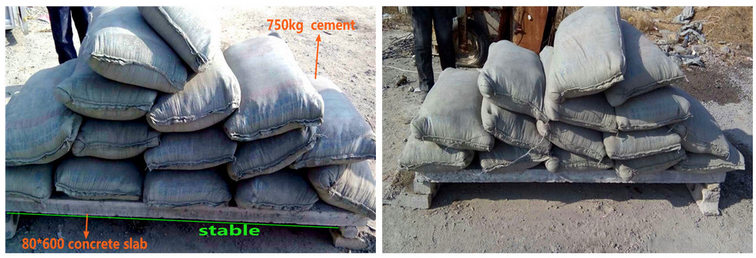

HQJ 50-300 Lightweight concrete wall panel forming machine

Quick Details

· Condition: New

· Application: prefab building

· Automatic Grade: Automatic

· Production Capacity: 60-70m/h

· Place of Origin: Shandong, China (Mainland)

· Brand Name: LING FENG

· Model Number: SL80*600

· Voltage: 360v

· Power(W): 4.5-8.0kw

· Dimension(L*W*H): 2.5*1.0*1.0m

· Weight: 2.0T

· Features: high efficiency

· Certification: ISO9001/CE

· Warranty: 12 months

· After-sales Service Provided: Engineers available to service machinery overseas

· Main frame: 2.0*1.4m

· Color steel thickness: 0.3-0.8 mm

· Insulation: first class

· Shaft axis: diameter 80

· Brick Raw Material: Cement, sand, stone.

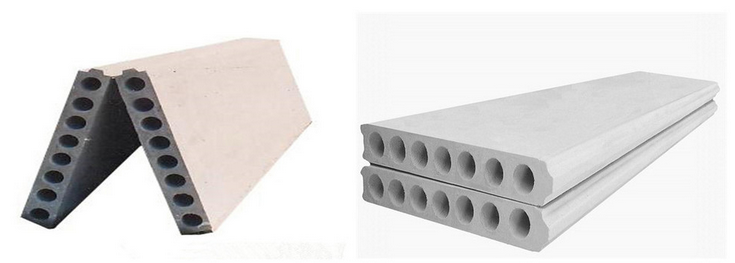

· Strength: water proof, fireproof, sound proof

· Vibrator type: ZW type 3.0kw

· Motor model: YEZ132S-4-B5

· Color: yellow or custom

· OEM: available

Products

Quality

Packaging & Delivery

Packaging Details: Wooden case and wood flour into the bottom of the box.

Delivery Detail: Within 15 days

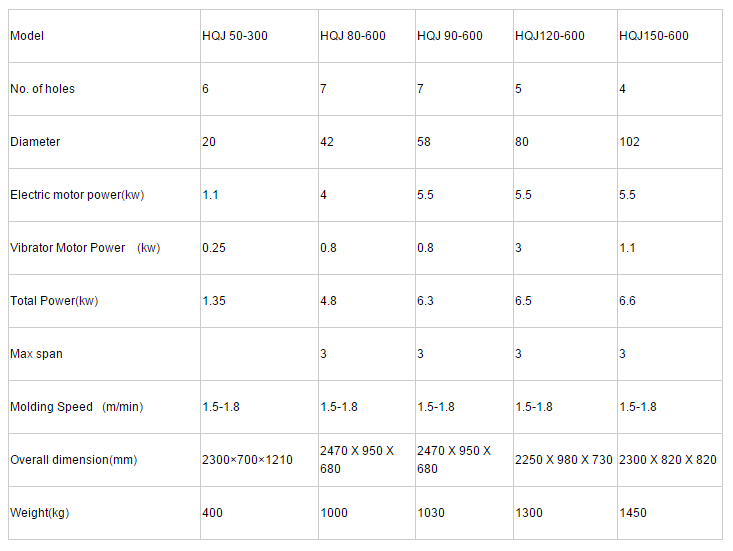

Major Parts and advantage of lightweight wall panel machine

Features:

I. Anti-corrosion and wear-resistant.

The machine frame is made of manganese steel whose quality is better than normal steel. The interior side of the mould is made of stainless steel (its thickness can be 2.2mm) which can stand repeated use and corrosive materials. It can be used for over 10 years. Besides, panels made by this kind of machine have better quality than other kinds. The panel will not be deformed. Its surface is smoother than others.

II. High capacity

Normal hollow core wall panel machine can make only ten panels in one mould, but this machine can make 14 panels at one time.

III. Energy-saving

The machine uses storage battery as power which can save a lot of electricity and is safe to use. Besides, if there is something wrong with the machine in the production line, it will not influence the use of other machines.

IV. Lower the cost of production

We use stainless steel for the mould instead of traditional steel. Steel mould machines need brushing de-molding agent or the panels can't be taken out. Stainless steel machines need a little de-molding agent, this can save both labor and material cost for manufacturers.

V. Hydraulic mould closing and opening

The mould is opened and closed by hydraulic. Its moving is very smooth and stable. All the four sides of the mould can be opened together, so it is very easy to use and it can save labor and cost.

VI. Unique design

We have special design not only for the single machine, but also for the whole production line. Our mixer can be customized for the customer according to their requirement. We also have special equipment to get rid of the dust so that the production is very clean.

Our Services

Interests in the good faith, interests in quality, interests in the service

Customer visits and technical guidance provides 24-hour service and lifetime maintenance services, supply of spare parts. Site church consumer operation, teach operating essentials, equipment maintenance and production experience, considerations.

Our factory can produce all kinds of equipment and prefabricated factory accessories according to customer demand.

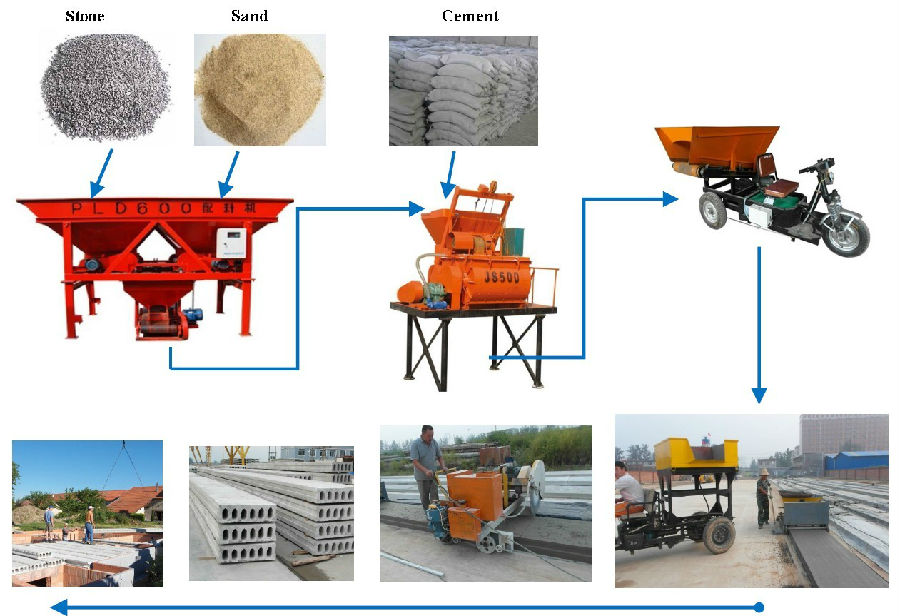

Flow chart:

Other available machines:

- Q:i need machinery to make MDF out of palm tree branches

- Please list your technical expertise, financial resources, experience with industrial machinery, desired output, size of facility, level of automation desired, marketing expertise, and location (so I can estimate level of governmental interference with environmental concerns). When you provide that background information your question has a shot at being answered.

- Q:i'm trying to record my band's demos onto a cassette recorder/mixer, and then get them onto cds. is there a piece of machinery that can transfer an audio tape onto a cd?

- I don't know if you want to do this but your question reminds me of my Mp3x blastr I have it plays everthing and convert songs from tape to cd.It's cost 50 bucks for the mp3x blaster at a office depot or any place that sales pc equipment.It comes wit a disk and a hookup for cd player,tape player,etc.Even thought it cost 5o bucks it will be the best 50 bucks you spent.

- Q:I'm looking to get into the t shirt business. From those already in the industry, what is the best machinery? Thank you.

- call brownstone t shirts north hollywood ca tell them you need silk screening done and ask them what kind of machineary the use

- Q:the metalic variety

- I would have to see it to tell you but stamping,casting or machining are the most common.

- Q:Survey: What is your favorite thing to do while operating heavy machinery?

- drink Nyquil. Outta the way Giant Koala Bear who strangely looks kinda like my supervisor!

- Q:whats the best exersise machine to use for 30 mins 5 times a week for losing thigh weight and bum weight?i was thinking a tredmill? but could a cross trainer give better results? whatever the answer give specifics and if you can try and like make my timetable better or more likely to lose weight!

- I've had a lot of luck with the elliptical machine. If you can increase your time to 45 minutes, even better.

- Q:You could easily make a drink like cool aid with a spoon, water and a packet of flavoring. But when your business for drinks gets really big, like Gatorade, what equipment do they use to produce their drinks?I have a project going on where i have to determine what kind of specalized equipment i will need. I'm making a drink. So what kind of 'specialized equipment' would i need for my business?

- It's all custom made equipment. Do a search for packaging equipment. Good luck*

- Q:Names of some artists that combine machinery with nature?

- Look at Roxy Paine's Dendroids and Replicants series.

- Q:Poll: Can you operate heavy machinery?

- Literally, yes. My father is a construction worker, and I've operated a backhoe and a forklift.

- Q:Was Cleopatra vii the token virgin in the play? Which means she was the virgin mother of Jesus. She is mentioned at Revelation 17;1 as the woman who committed fornication with the ruler of the world. In case you don't know fornication is intercourse and makes babies. There was only one ruler of the world. Julius Caesar. The adopted father of Octavian who inherited his fathers kingdom. The Roman Empire. If you doubt that drive over to Rome and take a look see.

- Umm... sure. Whatever. backs away slowly.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Lightweight concrete wall panel forming machine HQJ 50-300

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords