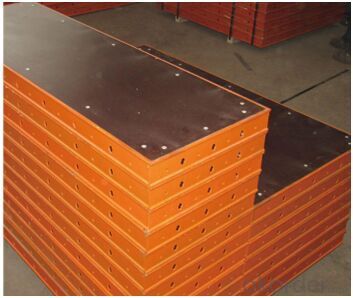

Light Steel Frame Formwork for Lower Builidng Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 90000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Light Steel Frame Formwork

Light duty steel frame of this kind is weighing lightly while bearing high capacity and in some sense it will reduce human cost for customers.

2. Main Features of light steel frame formwork

Light with reasonably big sizes

Easily assemble with convenient use to reduce construction use and work load

Easy to get rid of concrete surface

More than 20 times repeated use

Warmth keeping for winter concrete use

Convenient for maintenance on site. One surface damaged , the other surface can be quickly replace.

Mainly used for vertical, horizontal and shear formwork in high building.

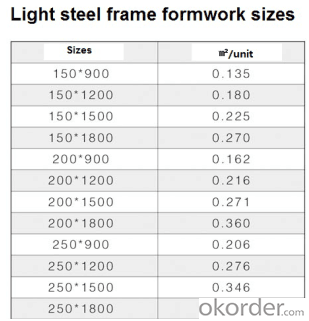

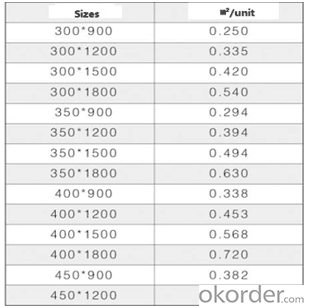

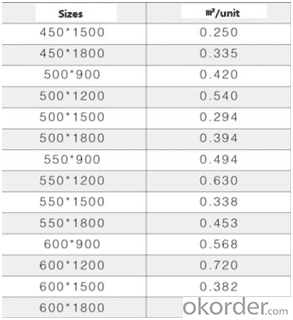

4. Light Steel Frame Formwork Specifications

5. FAQ of Light Steel Frame Formwork

1) What can we do for you?

.We can ensure the quality of the Light Steel Frame Formwork and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your projects.

2) What promises can be done by us?

. please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issues.

3) What about of our after-sale services?

. Response will be carried out in 24hours after receiving any complain or request.

. Any formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: wood package and adhesive tape

.Shipping: by sea

Shipping time: Normally small orders, it just1week business days to arrive your hand; When comes to the customs declaration, it may need 2weeks.

- Q:Does steel frame formwork require any specific edge protection measures?

- Specific edge protection measures are necessary for steel frame formwork. These measures are crucial to ensure worker safety and prevent accidents or falls from heights. Given that steel frame formwork is commonly used for construction purposes and involves elevated work, it is imperative to have appropriate edge protection measures in place. One prevalent method of edge protection for steel frame formwork involves installing guardrails or handrails along the exposed edges. These guardrails, typically made of sturdy materials like steel, serve as physical barriers to prevent accidental falls. They should be positioned at an appropriate height and capable of withstanding the required loadings as per safety regulations. In addition to guardrails, toe boards can be installed at the lower edge of the formwork to prevent falling materials or tools from posing hazards below. Made of plywood or similar materials, toe boards are securely fixed to the steel frame formwork to create a barrier. Furthermore, safety nets or catch platforms can be utilized as an additional measure for edge protection. These nets are placed below the working area to catch any falling objects or act as a secondary safety measure in case of a fall. It is crucial to properly install and regularly inspect safety nets, ensuring they meet relevant safety standards. It is worth noting that the specific edge protection measures required for steel frame formwork may vary based on local safety regulations and the height of the work being performed. Consequently, consulting relevant safety guidelines and seeking professional advice is essential to comply with necessary edge protection measures.

- Q:How does steel frame formwork handle the placement of concrete in structures with complex geometries or irregular shapes?

- Steel frame formwork is a versatile and efficient solution when it comes to handling the placement of concrete in structures with complex geometries or irregular shapes. This type of formwork system offers several advantages that make it suitable for such scenarios. Firstly, steel frame formwork provides a high degree of flexibility in terms of adjusting to different shapes and configurations. The modular nature of steel frames allows for easy customization and adaptation to accommodate complex geometries. This enables the construction of structures with irregular shapes, curves, and varying angles. Additionally, steel frame formwork offers excellent strength and stability. The rigid steel frames provide a solid support structure, ensuring that the formwork maintains its shape during the pouring and curing of concrete. This stability is crucial when dealing with complex geometries, as it prevents any deformations or misalignments that could compromise the structure's integrity. Moreover, steel frame formwork is highly durable and can withstand the pressure exerted by the concrete during pouring and curing. This durability is essential when dealing with complex structures, as it ensures that the formwork remains intact and can handle the weight and force of the concrete. Furthermore, steel frame formwork allows for easy and efficient installation and dismantling processes. The modular components can be quickly assembled and disassembled, enabling smooth transitions between different sections and shapes. This saves time and labor costs, making it a cost-effective solution for projects with complex geometries. In conclusion, steel frame formwork is an ideal choice when handling the placement of concrete in structures with complex geometries or irregular shapes. Its flexibility, strength, durability, and ease of installation make it a reliable and efficient solution for achieving the desired concrete structure with precision and accuracy.

- Q:What types of projects are steel frame formwork commonly used for?

- Steel frame formwork is commonly used for various types of projects, such as high-rise buildings, bridges, tunnels, and large-scale infrastructure projects. It provides a sturdy and reliable structure that can withstand heavy loads and ensure the efficient construction of concrete elements.

- Q:What are the different types of support systems used with steel frame formwork?

- There are several different types of support systems that can be used with steel frame formwork in construction projects. These support systems are designed to provide stability and strength to the formwork, ensuring that it can withstand the weight and pressure of the concrete being poured. One common type of support system used with steel frame formwork is adjustable steel props. These props are adjustable in height and can be easily positioned to support the formwork at the desired level. They are typically used in conjunction with horizontal beams to provide additional support. Another type of support system is horizontal beams, also known as walers. These beams are typically made of steel or aluminum and are used to distribute the weight of the formwork across a larger area. They are placed horizontally and are secured to the vertical supports or props, providing additional stability to the formwork. In addition to adjustable props and horizontal beams, diagonal or cross-bracing can also be used as a support system. These diagonal members are typically made of steel and are used to provide additional rigidity and stability to the formwork. They are installed diagonally between the vertical supports or props, creating a triangular structure that helps to prevent the formwork from collapsing or deforming under the weight of the concrete. Finally, tie rods or tie wires can also be used as a support system for steel frame formwork. These rods or wires are used to secure the formwork panels together, creating a tight and rigid structure. They are typically placed at regular intervals along the formwork panels and are tightened to provide additional support and stability. Overall, the different types of support systems used with steel frame formwork are adjustable steel props, horizontal beams, diagonal or cross-bracing, and tie rods or tie wires. Each of these support systems plays a crucial role in ensuring the strength and stability of the formwork during the concrete pouring process.

- Q:What are the lead times for manufacturing steel frame formwork?

- The lead times for manufacturing steel frame formwork can vary based on multiple factors. These factors encompass the intricacy of the design, the required quantity, the availability of raw materials, and the current workload of the manufacturer. Typically, smaller and less complex steel frame formwork orders can be completed within a few days to a couple of weeks. These orders are generally straightforward and do not involve extensive fabrication processes, allowing for swift completion. Conversely, larger and more complex steel frame formwork orders may require several weeks or even months to complete. These orders necessitate ample time for design, engineering, fabrication, and quality control processes. Furthermore, if there is a high demand for steel frame formwork or if the manufacturer is facing a heavy workload, the lead times can be further extended. It is crucial to note that external factors, such as transportation delays, unforeseen production issues, or the need for customizations, can also influence lead times. Consequently, it is advisable to directly contact the manufacturer for an accurate estimation of the lead time for a specific steel frame formwork order.

- Q:Can steel frame formwork be used for retaining walls or foundation structures?

- Yes, steel frame formwork can be used for both retaining walls and foundation structures. Steel frame formwork offers a high level of strength and durability, making it suitable for these types of structural elements. Additionally, it provides the necessary support and stability required during the construction process.

- Q:What are the different types of edge systems available for steel frame formwork?

- There are various types of edge systems available for steel frame formwork, including chamfer strips, fillet strips, bevelled edge forms, and bullnose forms. These edge systems are designed to create smooth and precise edges on concrete structures, ensuring a professional and finished look.

- Q:Are there any specific design considerations for steel frame formwork?

- Steel frame formwork has several important design considerations. Firstly, it is crucial to ensure that the steel frame is sufficiently strong and rigid to support the weight of the concrete. This entails determining the appropriate size and dimensions of the steel members, as well as the spacing and arrangement of the supports. Another key consideration is the ease of assembly and disassembly of the formwork. It is important to design the steel frame formwork in a manner that allows for quick and efficient installation and removal. This can have a significant impact on the overall construction timeline and cost. Additionally, the design should take into account potential lateral forces, such as wind or concrete pressure. It is essential to adequately brace and support the steel frame formwork to resist these forces. This may involve incorporating diagonal bracing or tie rods to enhance stability and prevent deformation of the formwork. Deflection of the formwork is another issue that needs to be addressed in the design. Steel frames have a tendency to deflect under the weight of the concrete, which can result in uneven surfaces or dimensional inaccuracies. To mitigate this, the formwork should be designed with sufficient stiffness and rigidity to minimize deflection and maintain the desired shape and dimensions of the concrete elements. Furthermore, the design should consider the reusability of the steel frame formwork. Steel is a durable material, and well-designed formwork can be used for multiple construction cycles, reducing waste and overall project costs. This requires careful attention to material selection, surface treatment, and the overall durability of the formwork components. In conclusion, specific design considerations for steel frame formwork include strength and rigidity, ease of assembly and disassembly, resistance to lateral forces, prevention of formwork deflection, and reusability. A well-designed steel frame formwork system can contribute to efficient and cost-effective construction processes.

- Q:How does steel frame formwork affect the overall aesthetics of a structure?

- The overall aesthetics of a structure can be significantly influenced by steel frame formwork. One of the main benefits of using steel frame formwork is its capacity to produce clean and smooth surfaces. During the pouring process, the steel frames are designed to securely hold the concrete, resulting in straight lines and sharp corners in the final structure. In contrast to conventional formwork materials like wood, steel frame formwork does not deform or bend under the weight of the concrete. As a result, the finish is more uniform and visually appealing, without any visible imperfections caused by uneven formwork. Furthermore, steel frame formwork offers greater design flexibility. The frames can be easily adjusted and modified to accommodate complex shapes and intricate details, allowing architects and designers to create unique and visually striking structures. This versatility is particularly important in modern architecture, where aesthetics play a crucial role. Moreover, the use of steel frame formwork can also positively impact the durability and longevity of a structure. Steel is a highly robust material that can withstand harsh weather conditions and resist corrosion, ensuring that the formwork maintains its structural integrity over time. This durability contributes to the overall aesthetics of the structure, as it allows for a long-lasting and visually pleasing appearance. In conclusion, steel frame formwork enhances the overall aesthetics of a structure by providing clean and smooth surfaces, allowing for greater design flexibility, and ensuring durability and longevity. Its ability to create visually appealing finishes and maintain structural integrity makes it a preferred choice for architects and designers seeking aesthetically pleasing results.

- Q:How does steel frame formwork prevent leakage and seepage of concrete during pouring?

- Leakage and seepage of concrete during pouring can be prevented by steel frame formwork through various mechanisms. To begin with, the steel frame formwork is meticulously designed to guarantee tight joints and connections, leaving no room for any gaps or openings through which the concrete might escape. The formwork is carefully aligned and secured, creating a watertight seal that minimizes the risk of leakage. Furthermore, high-quality materials resistant to water penetration are utilized in the construction of steel frame formwork. The steel panels employed in the formwork are typically coated with protective layers such as galvanized or epoxy coatings, acting as a barrier against water and safeguarding the concrete pouring process from any compromise. Moreover, steel frame formwork is engineered with ample support and bracing to endure the pressure exerted by the concrete during pouring. This guarantees the stability and integrity of the formwork, further reducing the likelihood of leakage or seepage. Additionally, steel frame formwork often incorporates additional sealing elements like rubber gaskets or foam strips in critical areas prone to leakage or seepage, such as corners or joints. These components provide an extra layer of protection, aiding in the creation of a tight seal and preventing any unwanted water ingress. In conclusion, the combination of precise design, high-quality materials, proper support, and additional sealing elements in steel frame formwork proves to be an effective solution in preventing leakage and seepage of concrete during pouring. This ensures the preservation of the poured concrete's integrity and quality, resulting in a durable and dependable structure.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Light Steel Frame Formwork for Lower Builidng Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 90000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products