new plastic formworks used in construction industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Main Introduction of Plastic Formwork:

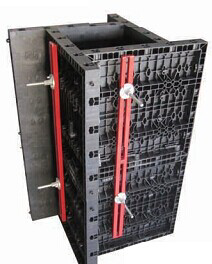

Hot rolled deformed steel framework. the peripheral board is made of FRTP plastic template and add some steel ribssupporting the panel welding a new type of industrialization combined template.which is mainl. The biggest panel is 120x60cm, weight only 10.5kg, which can be lift and set up by only one person easily, need no crane on the site.

2. The Advantages of Plastic Formwork:

-easy set up

Different size of panels can be firmly locked by simply turn the special handles to 90 degree. The panels have rib on the back, which makes the

system need not traditional wood blocks and nails. The panels have holes to fit tie rod, guarantee the strength of the whole system.

-modularity

Modular formwork composed by different size of panels, the main item is 120x60 panel, the size is 120x60cm, which used for the large area of walls

and slabs. There are also small size of panels like 10x60 panel (10x60cm), 20x60 panel (20x60cm), 25x60 panel (25x60cm), inner corner (20x20x60cm) and outer corner (10x5x60cm). Due to the variety of panel size, the system can form almost all size walls120x60 panel (act size 120x60cm) of multiple by 5cm. The material of modular formwork is PC-ABS mixied with special glass fibres which enable panels to hold high pressures.

-strength

The handles are made by high strength Nilon, each panel locked by at least 4 handls, which makes the whole system strong enough to pour 40cm walls.

-enviroment friendly

The system need not cut and nail due to the variety size, and nearly need no wood, the material can be recycled after broken, will not pollute the enviroment.

-consequent

Concrete does not stick to plastic, thus the panels need no oil before using, and can be cleaned simply by water. The surface of the wall which built by modular formwork is smooth, can be left without rework.

3. Images for Plastic Formwork:

4. FAQ of Plastic Formwork

1) What can we do for you?

We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in plastic formwork, please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

- Q:How does steel frame formwork handle the placement of fire-rated barriers and partitions within the concrete structure?

- Steel frame formwork provides a robust and efficient solution for the placement of fire-rated barriers and partitions within a concrete structure. With its strong and durable nature, steel frame formwork ensures the accurate positioning and alignment of these fire-rated elements. The rigid framework allows for precise installation, ensuring that the barriers and partitions are securely embedded within the concrete structure, providing reliable fire protection. Additionally, steel frame formwork allows for easy adjustment and modification when necessary, making it a versatile choice for incorporating fire-rated barriers and partitions into the concrete structure.

- Q:How is the stability of steel frame formwork ensured during the construction process?

- The stability of steel frame formwork is ensured during the construction process through several measures. Firstly, the steel frame formwork is designed and engineered to withstand the loads and pressures exerted during the concrete pouring and curing process. The frame is typically made of high-quality steel that has been tested for its strength and durability. To further enhance stability, bracing systems are installed at regular intervals along the formwork. These braces provide additional support and prevent any deformation or collapse of the formwork. The bracing systems are carefully designed and installed to withstand the lateral forces and ensure the formwork remains stable throughout the construction process. In addition, proper installation and anchoring of the steel frame formwork are crucial for its stability. The formwork is securely fixed to the ground or supporting structure using various anchoring systems, such as ground anchors or wall ties. These anchoring systems prevent any movement or displacement of the formwork, ensuring its stability. Regular inspections and maintenance are also conducted during the construction process to ensure the stability of the steel frame formwork. Any signs of damage, deformation, or wear are promptly addressed and repaired to prevent any compromise in stability. Moreover, adherence to safety regulations and guidelines is essential in ensuring the stability of the steel frame formwork. Construction workers are trained to follow proper procedures and protocols while handling and working with the formwork. This includes ensuring proper placement and alignment, avoiding overloading, and maintaining a safe working environment. Overall, the stability of steel frame formwork is ensured through careful design, proper installation, regular inspections, and adherence to safety guidelines. These measures collectively contribute to the safe and efficient construction process while minimizing the risk of accidents or structural failures.

- Q:Can steel frame formwork be used for circular columns?

- Circular columns can indeed be constructed using steel frame formwork. The versatility of steel frame formwork enables it to effortlessly adapt to various shapes and sizes, including circular columns. Its adjustability feature allows for easy customization to meet specific project needs. By utilizing adjustable steel frames, the formwork can be shaped to create a circular mold for pouring concrete and shaping circular columns. This renders steel frame formwork an appropriate option for construction endeavors involving circular column structures.

- Q:Can steel frame formwork be easily repaired or modified on-site?

- On-site repairs or modifications to steel frame formwork are easily achievable. Steel, being both durable and strong, can withstand heavy loads and harsh conditions. Should any damage occur or modifications be necessary, it is simple to replace or alter the affected or unwanted portions. Typically, the steel frame formwork system consists of modular components that can be easily disassembled and reassembled as required. This flexibility allows for straightforward on-site repairs or modifications without the need for extensive construction. Furthermore, the use of standardized components in steel frame formwork simplifies the process of finding replacement parts if necessary. All in all, the repair or modification of steel frame formwork on-site is a relatively uncomplicated and direct procedure.

- Q:How does steel frame formwork compare to plywood formwork?

- Steel frame formwork and plywood formwork are two commonly used methods of construction formwork, each with their own advantages and disadvantages. One major difference between steel frame formwork and plywood formwork is their durability. Steel frame formwork is highly durable and can be reused multiple times, making it a cost-effective option in the long run. On the other hand, plywood formwork tends to have a shorter lifespan and may require frequent replacements, resulting in higher costs. In terms of strength, steel frame formwork offers superior load-bearing capacity compared to plywood formwork. This makes it suitable for heavy-duty construction projects where high loads need to be supported. Plywood formwork, while not as strong, can still be effective for lighter construction projects. Another difference lies in the ease of assembly and disassembly. Steel frame formwork is typically easier to assemble and dismantle due to its modular design. This allows for faster construction progress and increased efficiency. Plywood formwork, while generally straightforward to use, may require more time and effort to assemble and disassemble. Both steel frame formwork and plywood formwork have their advantages in terms of flexibility and versatility. Steel frame formwork can be easily adjusted to different shapes and sizes, making it suitable for complex construction designs. Plywood formwork, though less flexible, can still be adapted to various construction projects with proper modifications. In terms of cost, steel frame formwork is generally more expensive upfront due to the higher material and manufacturing costs. However, its long-term durability and reusability can offset these initial costs. Plywood formwork, on the other hand, tends to be more affordable initially but may require more frequent replacements, resulting in higher overall costs over time. Ultimately, the choice between steel frame formwork and plywood formwork depends on the specific requirements of the construction project. Factors such as load-bearing capacity, durability, flexibility, and cost must be carefully considered to determine the most suitable formwork method for a particular construction project.

- Q:How does steel frame formwork contribute to the overall speed of construction?

- Steel frame formwork contributes to the overall speed of construction by providing a durable and reusable system that allows for efficient and quick assembly and disassembly of concrete structures. Its lightweight and modular design enables faster installation and dismantling, reducing construction time significantly compared to traditional timber formwork. Additionally, steel frame formwork offers high precision and accuracy, ensuring faster and more accurate concrete pouring, thus accelerating the overall construction process.

- Q:What types of projects are steel frame formwork suitable for?

- Steel frame formwork is suitable for a wide range of construction projects, particularly those that require a strong and durable formwork system. Some of the projects that steel frame formwork is commonly used for include high-rise buildings, bridges, tunnels, dams, and large-scale infrastructure projects. Due to its robustness and ability to withstand heavy loads, steel frame formwork is an ideal choice for projects that involve pouring concrete in large quantities or require a high level of structural integrity. The steel frame provides excellent support and stability, ensuring that the formwork system can withstand the pressure exerted by the wet concrete. Furthermore, steel frame formwork is highly adaptable and can be easily customized to suit different project requirements. It can be adjusted to accommodate various shapes, sizes, and dimensions, making it suitable for projects that involve complex architectural designs or unique structural elements. Additionally, steel frame formwork is reusable, which makes it a cost-effective option for projects that require repetitive casting of concrete elements. In summary, steel frame formwork is well-suited for projects that demand strength, durability, and versatility. Its ability to handle heavy loads, adapt to various shapes, and be reused makes it an excellent choice for high-rise buildings, bridges, tunnels, dams, and large-scale infrastructure projects.

- Q:What are the different types of formwork bracing used with steel frame formwork?

- There are several different types of formwork bracing that can be used with steel frame formwork. These bracing systems are designed to provide support and stability to the formwork during the concrete pouring process. 1. Adjustable Steel Props: Adjustable steel props are commonly used as vertical bracing elements. They consist of a steel tube with a threaded end and a base plate. The props can be adjusted to different heights and are secured in place using locking pins. 2. Horizontal Steel Bracing: Horizontal steel bracing is used to provide lateral stability to the formwork. This type of bracing consists of steel tubes that are connected to the vertical props and secured using clamps or couplers. The bracing is typically installed at regular intervals along the length of the formwork. 3. Diagonal Bracing: Diagonal bracing is used to provide diagonal support to the formwork. This type of bracing is made up of steel tubes that are connected to the vertical props and secured using clamps or couplers. Diagonal bracing is typically installed at different angles to provide maximum stability. 4. Tie Rods: Tie rods are used to provide additional strength and stability to the formwork. They consist of steel rods that are threaded at both ends and are used to connect the formwork panels together. The tie rods are tightened using nuts and washers to hold the formwork in place. 5. Cross Bracing: Cross bracing is used to provide additional lateral stability to the formwork. This type of bracing consists of steel tubes that are connected diagonally between the vertical props. Cross bracing is typically installed at regular intervals to prevent any shifting or movement of the formwork. Overall, the different types of formwork bracing used with steel frame formwork are designed to provide support, stability, and strength to the formwork system during the concrete pouring process. These bracing systems ensure that the formwork remains in place and can withstand the pressure exerted by the concrete.

- Q:Can steel frame formwork be used for both light and heavy-duty concrete structures?

- Yes, steel frame formwork can be used for both light and heavy-duty concrete structures. Steel frame formwork is known for its durability and strength, making it suitable for various construction projects. For light-duty concrete structures, such as residential buildings or low-rise structures, steel frame formwork provides the necessary support and stability during the pouring and curing process. It allows for easy assembly and disassembly, enabling efficient construction. On the other hand, steel frame formwork is also capable of withstanding the high pressures and loads associated with heavy-duty concrete structures. These structures typically include high-rise buildings, bridges, and other large-scale infrastructure projects. The strength and rigidity of steel formwork ensure that it can handle the weight and forces exerted by the concrete, ensuring the structural integrity of the building or structure. In addition to its strength and durability, steel frame formwork offers advantages such as reusability, versatility, and accuracy. It can be easily customized to fit various shapes and sizes, allowing for flexibility in design. The use of steel formwork also results in smooth and precise concrete finishes, enhancing the overall aesthetics of the structure. Overall, steel frame formwork is a versatile and reliable choice for both light and heavy-duty concrete structures. Its strength, durability, and adaptability make it an ideal solution for various construction projects, ensuring the successful completion of the project while meeting the desired quality and safety standards.

- Q:How does steel frame formwork handle the pouring and curing of concrete?

- Steel frame formwork is a popular method used in construction for pouring and curing concrete. This formwork system consists of steel panels that are assembled together to create a temporary mold or framework for the concrete. When it comes to handling the pouring of concrete, steel frame formwork provides excellent support and stability. The steel panels are designed to be strong and rigid, ensuring that they can withstand the pressure exerted by the wet concrete. This is particularly important in situations where large volumes of concrete need to be poured, or when the concrete needs to be poured at high heights. The steel frame formwork is typically set up and secured in place before the concrete is poured. This ensures that the formwork remains in position and prevents any movement or shifting during the pouring process. The formwork is carefully aligned and leveled to ensure that the concrete is poured evenly and accurately, resulting in a uniform and smooth finish. Once the concrete is poured, the steel frame formwork acts as a containment system, holding the concrete in place until it cures and hardens. The formwork prevents the concrete from spreading or sagging, resulting in a well-defined shape and structure. The steel panels also prevent any leakage or seepage of the concrete, ensuring that it remains contained within the desired area. During the curing process, the steel frame formwork provides the necessary support and stability for the concrete to gain strength. The formwork acts as a mold, allowing the concrete to set and harden in the desired shape and dimensions. This ensures that the final structure has the required strength and durability. In conclusion, steel frame formwork is an efficient and reliable method for handling the pouring and curing of concrete. It provides the necessary support, stability, and containment required for successful concrete placement. With its strength and rigidity, steel frame formwork ensures that the concrete cures properly, resulting in a high-quality and durable finished product.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

new plastic formworks used in construction industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products