Square Concrete Column Formwork AL65

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

Custom SF63 Rectangle / Square

Column / Wall Construction

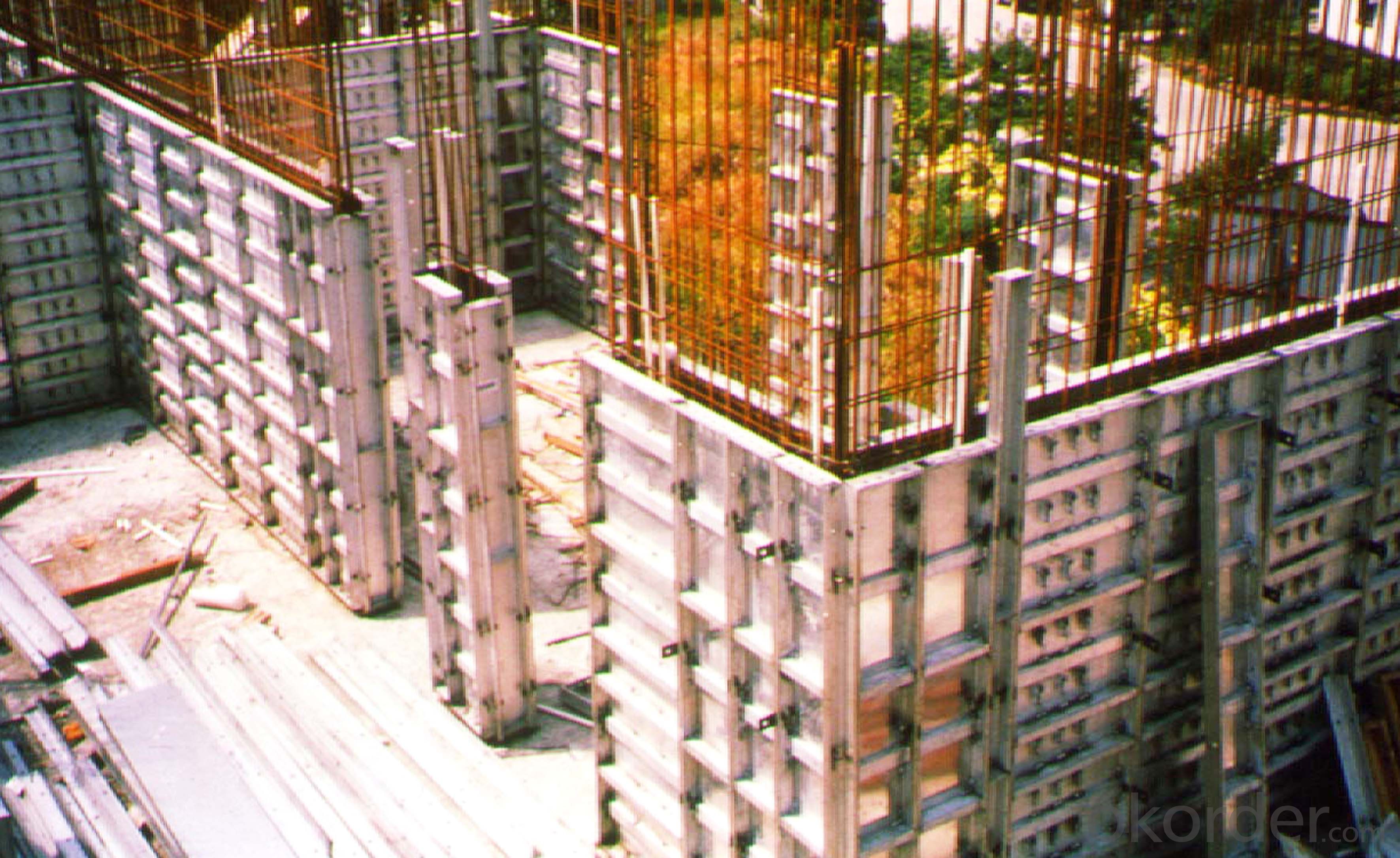

Adjustable Aluminum Formwork For Rectangle / Square Concrete Column

Description:

The whole system is made from aluminum materials. As the picture shown, every formwork unit is formed by CNBM production line. There are three special customized section bars form our standardization manufacture, and every formwork unit is welded by Robot.

AL 65 is a complete system with a full set of accessories, and can be set up flexibly according to project.

Competitive Advantage:

1. Lighter weight but high bearing capacity.

The allowable pressure from fresh concrete is 60KN/m2 with the thickness of 65mm.

2. Manual transportation can be achieved, greatly reduces the aggregate cost.

3. Perfect design, excellent produce and well welding make sure the flatness of concrete surface.

4. It is with the advantages of standard design, excellent applicability and interchangeable.

5. Simple, safe and fast.

6. No rust corrosion, easy maintenance, and high turnover rate.

Applications:

- Q:Can steel frame formwork be used in combination with post-tensioning techniques?

- Combining post-tensioning techniques with steel frame formwork is possible. Post-tensioning involves reinforcing concrete structures by inserting steel tendons into the concrete and then applying tension to the tendons once the concrete has cured. This method enhances the strength and durability of the structure. In contrast, steel frame formwork is a system utilized to create temporary molds for pouring concrete into desired shapes. It comprises steel frames, panels, and accessories assembled on-site. When implementing post-tensioning techniques, the steel tendons are typically positioned within the concrete prior to erecting the formwork. The steel frame formwork can be customized and adjusted to accommodate the tendons, ensuring their correct placement in the concrete. Moreover, steel frame formwork offers crucial support and stability during the post-tensioning process. The formwork system can withstand the forces resulting from tendon tension without distorting or collapsing, guaranteeing the concrete retains its desired shape and position. Hence, steel frame formwork is indeed compatible with post-tensioning techniques, offering an efficient and effective solution for constructing reinforced concrete structures.

- Q:PKPM steel frame design inside the full design of the nodes inside the connection parameters are determined by the design institute to teach me

- Design of node connection parameters according to the actual situation, you project such as beam column connection, the connection plate thickness, column, beam connection, bolt size and form... And so on, according to the specific requirements of your project

- Q:What are the common safety training requirements for using steel frame formwork systems?

- The common safety training requirements for using steel frame formwork systems include: 1. Proper understanding of the equipment: Users should be trained on the correct assembly, disassembly, and operation of the steel frame formwork systems. This includes knowing the different components, their purpose, and how they fit together. 2. Personal protective equipment (PPE): Trainees should be educated on the importance of wearing appropriate PPE such as hard hats, safety goggles, gloves, and steel-toed boots. They should understand how to properly use, maintain, and inspect their PPE to ensure its effectiveness. 3. Fall protection: Falling from heights is a significant risk when working with steel frame formwork systems. Safety training should cover the use of fall protection equipment such as harnesses, lanyards, and anchor points. Users should be trained on how to properly set up and use these systems to prevent falls. 4. Load capacity and weight limits: Steel frame formwork systems have specific load capacity and weight limits that must be adhered to. Training should focus on understanding these limits and how to calculate and distribute loads safely. Users should be aware of the risks associated with overloading and how it can compromise the stability and safety of the structure. 5. Proper handling and storage: Training should cover the correct methods for handling and storing steel frame formwork components. This includes techniques for lifting, moving, and securing the equipment to prevent accidents and damage. Users should also be educated on how to store the components to maintain their structural integrity and prevent rust or deterioration. 6. Hazard identification and mitigation: Safety training should emphasize the importance of identifying potential hazards on the construction site and implementing measures to mitigate them. Users should be trained to recognize and address hazards such as uneven ground, overhead obstructions, electrical hazards, and inclement weather conditions. 7. Emergency procedures: Trainees should be familiarized with emergency procedures, including evacuation plans, first aid, and reporting protocols. They should understand how to respond to accidents, injuries, or equipment failures and know how to communicate effectively in case of an emergency. Overall, safety training for using steel frame formwork systems is crucial to ensure the well-being of workers and the successful completion of construction projects. It is essential to provide comprehensive training that covers all potential risks and equips users with the knowledge and skills to work safely and efficiently with these systems.

- Q:What types of projects are steel frame formwork commonly used for?

- Steel frame formwork is commonly used for a wide range of construction projects that require the casting of concrete structures. Some of the common types of projects where steel frame formwork is utilized include: 1. High-rise Buildings: Steel frame formwork is extensively used in the construction of high-rise buildings due to its ability to bear heavy loads and provide stability. It allows for the efficient casting of concrete walls, columns, and slabs, ensuring the structural integrity of the building. 2. Bridges and Tunnels: Steel frame formwork is well-suited for constructing bridges and tunnels, as these structures require strong and durable formwork systems. The steel frames provide the necessary support and stability during the concrete casting process, ensuring the safety and strength of the final structure. 3. Industrial Structures: Steel frame formwork is commonly employed in the construction of large industrial structures such as warehouses, factories, and power plants. These projects often involve the casting of massive columns, beams, and walls, which can be efficiently achieved with steel frame formwork due to its strength and versatility. 4. Commercial Buildings: Steel frame formwork is widely used in the construction of commercial buildings, including shopping malls, hotels, and office complexes. The system allows for the quick and accurate casting of concrete elements, enabling faster construction timelines and reducing overall project costs. 5. Residential Buildings: Steel frame formwork finds application in the construction of residential buildings, ranging from single-family homes to apartment complexes. It provides a reliable and efficient solution for casting concrete walls, slabs, and staircases, ensuring the safety and stability of the residential structure. Overall, steel frame formwork is a versatile construction technique that can be adapted to various project types. Its strength, durability, and flexibility make it a popular choice for projects that require efficient and precise casting of concrete structures.

- Q:How does steel frame formwork affect the overall aesthetics of a concrete finish?

- Steel frame formwork does not directly affect the overall aesthetics of a concrete finish as it is primarily used for structural support and shaping the concrete during the pouring and curing process. However, the use of steel frame formwork can ensure a smooth and precise concrete surface, which can indirectly contribute to a better overall aesthetic appearance by minimizing surface imperfections and providing a clean and uniform finish.

- Q:Frame structure calculation of the material, the template area, and how to calculate the amount of wood, steel, fasteners, there is no common factor ratio? The column spacing of 6000

- I do not quite understand this knowledge on the Internet to help you find some. See if you can use it

- Q:Are there any specific design codes or standards that govern the use of steel frame formwork?

- Steel frame formwork is governed by specific design codes and standards. One well-known standard is the American Concrete Institute (ACI) 347-04, which provides guidelines for the design, construction, and use of formwork systems, including steel frame formwork, for concrete structures. In addition to ACI 347-04, there are other international standards and codes that may apply depending on the location and project requirements. For instance, the European Standard EN 12812:2008 provides guidelines for the design, performance, and use of falsework systems, which includes steel frame formwork. These codes and standards cover various aspects such as design criteria, material requirements, safety considerations, and construction practices. Their purpose is to ensure that steel frame formwork systems are structurally sound, safe, and capable of withstanding the loads and pressures exerted by the concrete during pouring and curing. Stability, bracing, tie spacing, and formwork accessories are also addressed by these design codes and standards to ensure the proper functioning of the steel frame formwork system. They also require the implementation of safety measures such as guardrails, handrails, and access platforms to protect workers during formwork assembly, use, and removal. Compliance with these codes and standards is essential to maintain the integrity of the structure, ensure worker safety, and successfully complete concrete construction projects. Architects, engineers, contractors, and formwork manufacturers must adhere to these guidelines and incorporate them into their design and construction processes when utilizing steel frame formwork.

- Q:Can steel frame formwork be used in projects with restricted working hours?

- Indeed, projects with restricted working hours can utilize steel frame formwork. This resilient and adaptable system allows for swift assembly and disassembly, enabling efficient construction even under time constraints. The steel frames provide strong structural support and can effortlessly be adjusted to accommodate diverse concrete structures. Furthermore, steel frame formwork boasts high reusability, reducing the necessity for excessive construction materials and consequently minimizing formwork installation time. In conclusion, steel frame formwork offers flexibility, efficiency, and durability, making it an optimal choice for projects with limited working hours.

- Q:What are the different types of formwork bracing used in steel frame formwork systems?

- There are various types of formwork bracing used in steel frame formwork systems, including diagonal bracing, horizontal bracing, vertical bracing, and cross bracing. These bracing systems provide stability and support to the formwork structure, ensuring that it can withstand the loads and pressures exerted during the concrete pouring process.

- Q:What is the maintenance required for steel frame formwork?

- The maintenance required for steel frame formwork involves regular cleaning, inspection for any signs of damage or wear, and appropriate storage to prevent rusting or corrosion. Additionally, any necessary repairs or replacements should be carried out promptly to ensure the formwork remains in good working condition.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Square Concrete Column Formwork AL65

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords