column formwork accessories adjustable clamp

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 60000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

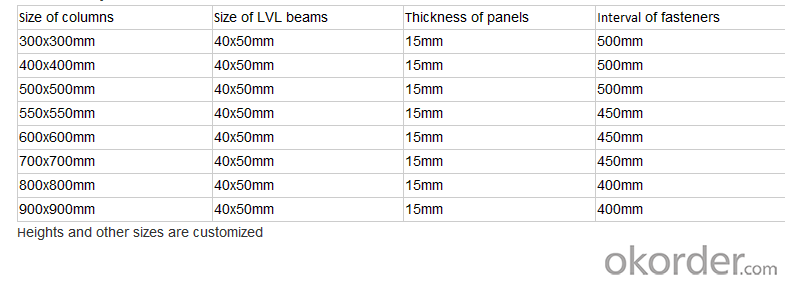

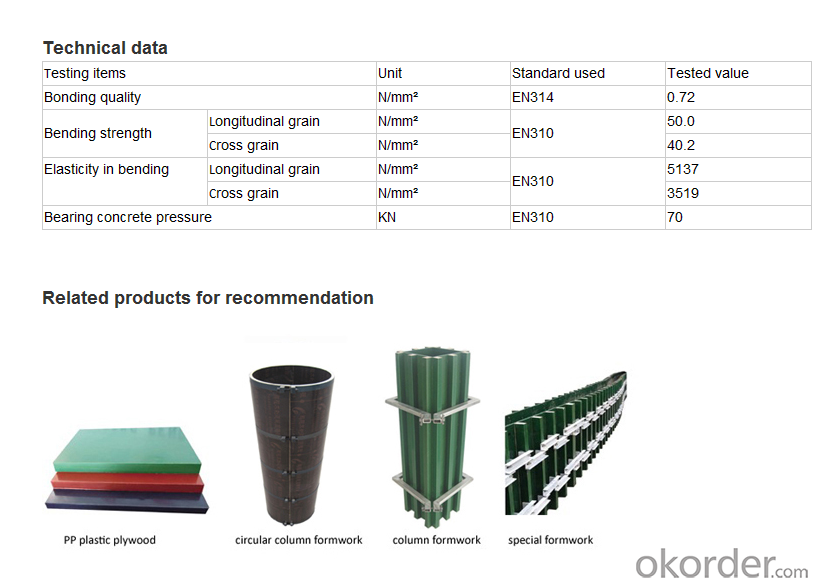

china quick form concrete column formwork

Application

column formwork for concrete forming of square columns

Installation

as easy as film faced plywood, but no need release agent

Dismantling

Handle carefully without violent damage and scratch to ensure more usage in good condition

Cleaning

Just clean by water

Maintenance & Storage

No oil treatment, place the panel flat, away from direct sunlight and water.

Product options

Advantages

1. reusable 50 times at least

2. quick installation & seamless joining to prevent the leakage of concrete

3. painted accessories, high resistance to rust

4. quick dismantling without concrete release agent

5. nice concrete finish without reworkP

Packing

- Q:What are the different components of steel frame formwork?

- The steel frame formwork typically consists of various components: 1. Panels serve as the primary element of the system, made from steel or aluminum. They are designed to be lightweight yet sturdy, coming in different sizes, shapes, and thicknesses based on the required strength and load-bearing capacity. 2. To ensure a tight and secure formwork system, connecting pins made of steel are used to join the panels together. These pins are inserted through pre-drilled holes in the panels, providing stability and preventing any movement or displacement during concrete pouring. 3. Wedges, usually made of steel or plastic, are used in conjunction with the connecting pins to further secure the formwork system. They are inserted between the panels and pins, creating a tight fit and preventing any gaps or spaces that could lead to leakage or uneven concrete placement. 4. Props are vertical support devices made of steel, providing additional strength and stability to the formwork system. They can be adjusted in height, allowing flexibility in formwork installation. Props play a crucial role in supporting the weight of the concrete and formwork, ensuring a safe and reliable construction process. 5. Braces, made of steel, are horizontal or diagonal supports used to reinforce the formwork system and prevent any buckling or bending of the panels. They are installed at regular intervals, providing additional stability and rigidity to the formwork structure. 6. Various accessories, including clamps, ties, and brackets, may also be included in the steel frame formwork system. These accessories secure the formwork system to the existing structure, ensure accurate panel alignment, and provide additional reinforcement where necessary. Collectively, these components form a robust and reliable system for concrete construction. The combination of panels, connecting pins, wedges, props, braces, and accessories guarantees a strong and stable formwork structure capable of withstanding the pressures and forces exerted during the concrete pouring process.

- Q:How does steel frame formwork handle the placement of concrete in vertical or inclined structures?

- Steel frame formwork is a highly versatile and efficient system for handling the placement of concrete in vertical or inclined structures. Its sturdy steel frames provide excellent support and stability during the pouring process, ensuring that the concrete is smoothly and evenly distributed. The adjustable panels and accessories of the formwork system allow for flexibility in creating different shapes and sizes of concrete structures. Additionally, the steel frames are durable and reusable, making them cost-effective and environmentally friendly. Overall, steel frame formwork simplifies and streamlines the concrete placement process, resulting in high-quality and structurally sound vertical or inclined structures.

- Q:How does steel frame formwork handle different types of cured concrete removal techniques?

- The steel frame formwork system is designed to effectively handle various types of techniques for removing cured concrete. It is a versatile system that provides strength and durability, allowing it to withstand the forces generated during the removal process. One commonly used technique for concrete removal is mechanical chipping or breaking. This involves using a pneumatic or hydraulic breaker to chip away at the concrete surface. The steel frame formwork system offers a stable and rigid platform for the operator to work on, ensuring precise and controlled removal of the concrete. Additionally, the steel frame acts as a protective barrier, preventing damage to the surrounding areas. Another technique for concrete removal is hydro demolition, which utilizes high-pressure water jets to break down the concrete. The steel frame formwork system is capable of handling this technique due to its water resistance and ability to withstand the high-pressure water jets without sustaining damage. The structural integrity of the steel frame remains intact, providing a safe and efficient removal process. In some cases, chemicals or acids may be used to dissolve or soften the concrete for removal. The steel frame formwork system is resistant to corrosion, making it suitable for such techniques. It can withstand exposure to chemicals without deteriorating, ensuring a long-lasting and reliable formwork system. Furthermore, the steel frame formwork system can accommodate thermal techniques for concrete removal. For example, heat can be applied using torches or flame guns to break down the concrete. The heat resistance of the steel frame allows it to withstand high temperatures without warping or deforming. In conclusion, the steel frame formwork system is well-suited for handling various techniques for removing cured concrete. Its strength, durability, resistance to water and chemicals, and heat resistance make it a reliable choice for construction projects that require concrete removal.

- Q:How does steel frame formwork contribute to the overall safety of a construction site?

- Steel frame formwork contributes to the overall safety of a construction site by providing a sturdy and durable structure for concrete pouring. Its robustness ensures that the formwork can withstand the weight and pressure of wet concrete, minimizing the risk of collapse or structural failure. Additionally, the steel frame's rigidity helps maintain the accuracy and stability of the formwork system, reducing the chances of any accidents or errors during construction.

- Q:What are the common applications of steel frame formwork?

- Steel frame formwork is a versatile construction technology that is widely used in various applications. Some of the common applications of steel frame formwork include: 1. High-rise buildings: Steel frame formwork is commonly used in the construction of high-rise buildings due to its strength and durability. It provides a stable and rigid structure for concrete casting, allowing for efficient construction of tall structures. 2. Bridges and tunnels: Steel frame formwork is also frequently used in the construction of bridges and tunnels. Its robustness and ability to withstand heavy loads make it ideal for these types of infrastructure projects. 3. Industrial structures: Steel frame formwork is widely used in the construction of industrial structures such as factories, warehouses, and power plants. Its ability to handle large volumes of concrete and provide a sturdy framework makes it suitable for these applications. 4. Residential buildings: Steel frame formwork is commonly employed in the construction of residential buildings, including apartments, condominiums, and housing complexes. Its versatility allows for the creation of various shapes and sizes, accommodating different architectural designs. 5. Infrastructure projects: Steel frame formwork is crucial in infrastructure projects such as dams, canals, and water treatment plants. These projects often require large-scale concrete casting, and the strength of steel formwork ensures the integrity and stability of the structures. 6. Commercial and institutional buildings: Steel frame formwork finds extensive use in the construction of commercial and institutional buildings, including offices, schools, hospitals, and shopping malls. Its efficiency and cost-effectiveness contribute to faster construction timelines and reduced project costs. Overall, steel frame formwork is widely utilized in various construction applications due to its strength, durability, and versatility. Its ability to provide a stable framework for concrete casting makes it an essential technology in the construction industry.

- Q:How does steel frame formwork affect the overall sustainability of a construction project?

- Steel frame formwork can significantly enhance the overall sustainability of a construction project in several ways. Firstly, steel is a highly durable material that can be reused multiple times, reducing the need for constant replacements and minimizing waste generation. Additionally, steel frame formwork allows for efficient construction processes, resulting in shorter project durations and decreased energy consumption. Moreover, the use of steel formwork enhances structural integrity, reducing the need for maintenance and repairs in the long run. Lastly, steel is a recyclable material, promoting circular economy principles and reducing the environmental impact of the construction industry.

- Q:What are the key considerations for selecting the appropriate steel frame formwork supplier for international projects?

- When selecting the appropriate steel frame formwork supplier for international projects, there are several key considerations that should be taken into account. Firstly, it is important to assess the supplier's experience and track record in working on international projects. This includes evaluating their previous projects, particularly those that are similar in scale and scope to the project at hand. A supplier with a proven track record in successfully delivering international projects will likely have the necessary expertise and understanding of the specific requirements and challenges that may arise. Secondly, it is crucial to consider the supplier's ability to meet international standards and regulations. Different countries may have varying building codes and regulations that need to be adhered to, so it is essential that the supplier has experience in complying with these standards. This can help to ensure that the steel frame formwork supplied is of high quality and meets all necessary safety requirements. Additionally, the supplier's capacity to handle logistics and transportation for international projects should also be taken into account. This includes evaluating their ability to deliver the formwork to the project site in a timely manner, as well as their understanding of any customs and import/export requirements that may be involved. A supplier with a well-established network and efficient logistical capabilities can help to minimize delays and ensure smooth operations throughout the project. Furthermore, it is important to consider the supplier's after-sales support and technical assistance. International projects may require troubleshooting and technical guidance, so it is crucial that the supplier offers reliable support and assistance throughout the project duration. This can include providing training for onsite personnel, offering prompt responses to queries, and having a dedicated team to handle any issues that may arise. Lastly, the cost-effectiveness of the supplier's offerings should be evaluated. While it is essential to prioritize quality and reliability, it is also important to ensure that the supplier's pricing is competitive and aligns with the project's budget. This can be done through requesting detailed quotations and comparing them with other suppliers in the market. In conclusion, selecting the appropriate steel frame formwork supplier for international projects requires careful consideration of factors such as experience, compliance with international standards, logistical capabilities, after-sales support, and cost-effectiveness. By thoroughly assessing these key considerations, project stakeholders can make an informed decision and choose a supplier that is best suited to meet the project's requirements.

- Q:What are the different types of lifting and handling equipment used with steel frame formwork?

- There are several types of lifting and handling equipment commonly used with steel frame formwork. These include cranes, forklifts, hoists, and lifting clamps. Cranes are often used to lift and move large steel frames and formwork panels. Forklifts are used for transporting and positioning the formwork components on the construction site. Hoists are utilized for lifting and lowering formwork panels and other heavy materials. Lifting clamps are used to securely grip and lift steel formwork components, providing a safe and efficient handling solution.

- Q:What are the different sizes and dimensions available for steel frame formwork?

- The sizes and dimensions available for steel frame formwork vary depending on the manufacturer and specific project requirements. However, common sizes range from small panels measuring around 1 meter in height and width to larger panels that can be several meters in size. The dimensions can also be customized to fit specific project needs, ensuring flexibility and adaptability in construction processes.

- Q:What are the different types of stripping methods used with steel frame formwork?

- There are several different types of stripping methods used with steel frame formwork, including crane stripping, hydraulic stripping, and manual stripping. Crane stripping involves using a crane to lift and remove the formwork from the concrete structure. Hydraulic stripping utilizes hydraulic jacks to lift and separate the formwork from the concrete. Manual stripping involves manually dismantling and removing the formwork by hand. These methods offer varying degrees of speed, efficiency, and labor requirements depending on the specific project and requirements of the formwork system.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

column formwork accessories adjustable clamp

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 60000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords