Adjustable SF120 System for Rectangle SF120-A

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

concrete column formwork

aluminium formwork system

Adjustable SF120 System for Rectangle / Square Concrete Column

Description:

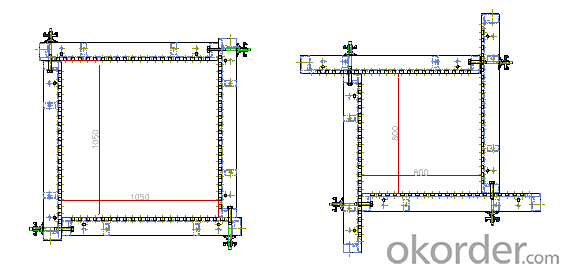

1. Structure sketch

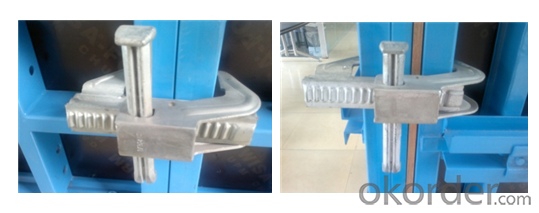

SF120-A is a kind of formwork for pouring rectangle & square column; it is composed of formwork, props, adjustable steel clamp, etc.

Competitive Advantage:

1. High-precision production line guarantees the perfect products.

2. Special hollow steel frame covered with WISA-plywood, light weight but high strength.

Its allowable pressure from fresh concrete is 80KN/m2 with the weight of 65KG/m2.

3. Easy connection with adjustable steel clamp.

4. The system is easy to change the cross section.

Applications:

Applications:

- Q:Can steel frame formwork be used for curved or irregularly shaped concrete structures?

- Curved or irregular concrete structures can indeed utilize steel frame formwork. The malleability of steel permits easy manipulation and shaping to accommodate diverse curves and irregularities in the concrete structure. The steel frame formwork provides essential support and stability during the pouring and curing stages, guaranteeing the desired concrete shape. It can be adjusted and tailored according to project-specific requirements, rendering it a versatile option for forming curved or irregular structures. Furthermore, steel frame formwork offers robustness and resilience, ensuring its ability to withstand the pressures and forces exerted throughout the concrete placement and curing process. In summary, steel frame formwork proves to be a suitable choice for achieving intricate and distinctive shapes in concrete construction projects.

- Q:Can steel frame formwork be used for both residential and commercial construction?

- Yes, steel frame formwork can be used for both residential and commercial construction. Its strength, durability, and versatility make it suitable for various construction projects, regardless of their scale or purpose.

- Q:How does steel frame formwork accommodate for changes in concrete thickness?

- Steel frame formwork is a flexible and adjustable system that allows for changes in concrete thickness during the construction process. It consists of steel panels and beams that can be easily repositioned or adjusted to accommodate varying concrete thicknesses. This is achieved through the use of adjustable wedges or bolts that hold the formwork together and can be loosened or tightened as needed. When the concrete thickness needs to be increased, additional panels can be added to the steel frame formwork system. These panels can be easily attached to the existing framework, ensuring a seamless connection and maintaining the structural integrity of the formwork. Conversely, if the concrete thickness needs to be reduced, panels can be removed from the formwork system. The adjustable wedges or bolts can be loosened, allowing for the removal of panels without compromising the stability of the structure. Steel frame formwork also allows for adjustments in other dimensions, such as length and width, to accommodate changes in the shape or size of the concrete structure. This flexibility makes it a versatile and efficient choice for accommodating changes in concrete thickness. Overall, the steel frame formwork system provides a convenient and adaptable solution for construction projects where the concrete thickness may vary. Its adjustable features ensure that the formwork can be easily modified to meet the specific requirements of the project, resulting in a smooth and successful construction process.

- Q:What type of concrete finishes can be achieved with steel frame formwork?

- With steel frame formwork, various concrete finishes can be achieved, including smooth surfaces, textured patterns, exposed aggregate, or even decorative finishes like stamped or stained designs. The steel frame formwork provides a sturdy and precise framework, allowing for the creation of different aesthetic effects and finishes on the concrete surface.

- Q:Can steel frame formwork be reused multiple times?

- Yes, steel frame formwork can be reused multiple times. Unlike traditional timber formwork, steel frame formwork is designed to be durable and long-lasting. It is made of high-quality steel, which ensures its strength and stability, making it suitable for multiple uses. Steel frame formwork can withstand the pressure and weight of concrete and can be easily cleaned and maintained after each use. This reusability makes steel frame formwork a cost-effective and environmentally friendly option for construction projects.

- Q:Can steel frame formwork be used for both horizontal and vertical concrete structures simultaneously?

- Yes, steel frame formwork can be used for both horizontal and vertical concrete structures simultaneously. Steel frame formwork is a versatile type of formwork system that is commonly used in construction projects. It consists of steel frames, typically made of steel tubes or channels, which are assembled to create the desired shape and dimensions of the concrete structure. The steel frames can be easily adjusted and secured in place, allowing for flexibility in creating both horizontal and vertical concrete structures. The formwork can be used to construct slabs, beams, walls, columns, and other structural elements. Steel frame formwork offers several advantages for simultaneous use in horizontal and vertical concrete structures. Firstly, it provides a strong and durable support system that can withstand the weight and pressure of the concrete. This ensures that the formwork remains stable and intact throughout the pouring and curing process. Secondly, steel frame formwork is reusable, which makes it a cost-effective solution for construction projects. Once a concrete structure is completed, the formwork can be disassembled and used again for other projects. This not only reduces construction costs but also minimizes waste and promotes sustainable construction practices. Additionally, steel frame formwork can be easily adjusted to accommodate changes in design or dimensions. This flexibility allows for efficient construction, as the formwork can be quickly modified to suit the specific requirements of the project. In conclusion, steel frame formwork is a suitable option for both horizontal and vertical concrete structures simultaneously. Its versatility, strength, reusability, and flexibility make it an efficient and cost-effective choice for construction projects.

- Q:Are there any restrictions on the type of concrete that can be used with steel frame formwork?

- Yes, there are certain restrictions on the type of concrete that can be used with steel frame formwork. One of the main factors to consider is the workability of the concrete. Steel frame formwork requires concrete that has good flowability and can easily be placed and compacted within the formwork system. Therefore, highly viscous or stiff concrete mixes may not be suitable for use with steel frame formwork. Another restriction is related to the concrete's time of setting and hardening. Steel frame formwork relies on concrete that can set and harden within a specific time frame to allow for the removal of the formwork. If the concrete used takes too long to set or harden, it may cause delays in the construction process and hinder the timely removal of the formwork. Additionally, the strength and durability of the concrete are important considerations. Steel frame formwork is often used for structures that require high strength and durability, such as high-rise buildings or infrastructure projects. Therefore, the concrete used should have sufficient compressive strength and be able to withstand any anticipated loads or environmental conditions. It is also important to consider the compatibility of the concrete mix with the steel frame formwork. Certain concrete additives or admixtures may not be compatible with the steel formwork system, leading to potential issues such as corrosion of the steel or compromised structural integrity. In summary, while there may not be strict restrictions on the type of concrete that can be used with steel frame formwork, there are certain considerations that need to be taken into account. The concrete should have good workability, set and harden within a specific time frame, possess sufficient strength and durability, and be compatible with the steel formwork system. Consulting with a structural engineer or construction professional can help ensure the appropriate type of concrete is selected for use with steel frame formwork.

- Q:Are there any size limitations for steel frame formwork panels?

- There are size limitations for steel frame formwork panels, but these limitations can vary depending on the specific manufacturer and the intended use of the formwork. Generally, steel frame formwork panels are available in standard sizes that range from 1.2 to 2.4 meters in width and 1.8 to 3.6 meters in height. However, it is important to note that custom sizes can also be manufactured to meet specific project requirements. The size limitations for steel frame formwork panels are influenced by several factors, including the weight and stability of the panels, ease of transportation and installation, and the requirements of the concrete structure being built. Larger panels may be more difficult to handle and transport, which could result in higher costs and logistical challenges. Additionally, larger panels may require additional support or bracing to ensure stability during pouring and curing of the concrete. It is recommended to consult with the manufacturer or supplier of the steel frame formwork panels to determine the specific size limitations for a particular system. They can provide guidance based on their expertise and experience, taking into account the project requirements, structural considerations, and practical aspects of using the formwork.

- Q:How to fix the glass brick on the steel frame

- Generally can use glass glue and steel frame fixed, pay attention not to use the corrosion of the glue, general neutral can.

- Q:How does steel frame formwork affect the overall construction schedule?

- Steel frame formwork can significantly impact the overall construction schedule in a positive way. Its use can expedite the construction process due to its high strength and durability, allowing for faster assembly and disassembly. The modular nature of steel frame formwork enables efficient repetition, resulting in quicker completion of repetitive tasks such as pouring concrete. Moreover, the adaptability and flexibility of steel frame formwork reduces the need for extensive modifications, further enhancing the construction timeline. Overall, steel frame formwork can expedite construction, leading to a more efficient and timely completion of the project.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Adjustable SF120 System for Rectangle SF120-A

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords