Large-span Prestressed Concrete Hollow Core Slab Making Machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Large-span Prestressed Concrete Hollow Core Slab Making Machine

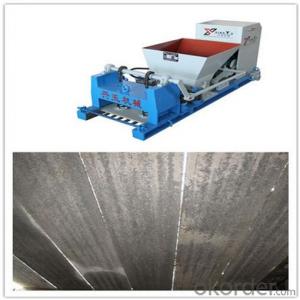

1. Structure of Large-span Prestressed Concrete Hollow Core Slab Making Machine:

The machine uses hydraulic lifting system, easy to revolve. It can reduce labor intensity and improve production efficiency. Machine body adopts anti-rust technology. Key parts, like hopper are welded by stainless steel. Wearing parts like reamers, side form, vibration board, stock guide and other parts are all welded with alloy. Both sides of the wall panels can put reinforcement wires, diameter can reach 6mm. Work area is orbital or no orbital.

According to the specialty of the local materials, we provide matching method to insure customer produce standard panels (general materials: fly ash, slag, ceramsite, cinders, cinerite, pumice, vermiculite and so on). Reduce the overall cost of building, increase indoor usable space.

High production efficiency, annual output square meters above 150000m.

2. Main Features of Large-span Prestressed Concrete Hollow Core Slab Making Machine:

• One machine can make one slab lower cost, high Wear-resistant, long service life.

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Simple structure, easy operate, less wear parts

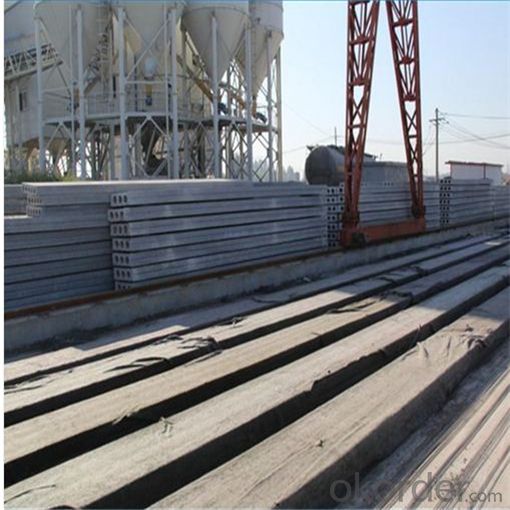

3. Large-span Prestressed Concrete Hollow Core Slab Making Machine Images:

4. Large-span Prestressed Concrete Hollow Core Slab Making Machine Specification:

Type | Aperture & diameter | Number and diameter of wires | Max span | Total power | Productivity (m/min) | Max. Load (KN/m2) | Overall dimension (mm) | Weight (kg) |

GLY180-1200 | 11/ peach | 12/9.5or12.7 | 9 | 18.5 | 1.1-1.3 | 16.16 | 2900X1500x1200 | 3300 |

GLY200-1200 | 8 /peach | 10/9.5or12.7 | 10 | 22 | 1.1-1.3 | 13.22 | 3700X1550X1550 | 5300 |

GLY250-1200 | 8/ peach | 10/12.7 | 12.6 | 33 | 1.1-1.3 | 11.1 | 3700X1550X1500 | 6200 |

GLY300-1200 | 6 /peach | 8/12.7 | 15 | 40 | 1.1-1.3 | 10.83 | 3700X1550X1500 | 6900 |

GLY380-1200 | 8 /rhomb | 8/12.7 | 18 | 39.2 | 0.8-1.0 | 12.27 | 4600X1850X1600 | 7500 |

Production Process

Rebar tensioning

Raw materials preparing

Molding

Our customers

5. Packing & Delivery

• Wire cables are used for fastening the machine on the trailer or inside the container.

• Machine covered with plastic film.

• Machines can be packed in tarpaulin or wooden case according to customer’s needs.

6. FAQ:

We have organized several common questions for our clients, may help you sincerely:

• What information we need to confirm with you before send a formal offer?

What kind of slab you want to make, wall panel, roof panel, lintel or something else?

Do you have exact slab size (slab thickness and width)? If not, please tell us the slab span, we will give you suggestion.

• Have you use this kind of machine before?

Our machine is totally different from European machine. Please don’t follow their instructions.

• How long can we receive the product after purchase?

In the purchase of product, within 20 working days we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 35 working days can be served.

• What kind of machine do you have?

Our main products: large span GLY concrete hollow core slab machine, light - weight wall panel machine, lintel machine, column machine, hollow core slab cutting machine, concrete feeding dumper, high-strength steel wire tensioning machine, which amount to more than the types and more than four hundred standards. We can provide the whole plan and technology supporting for concrete precast component.

7. Why choose us:

• 30 years manufacturing experience.

• Constitutor of the

• More than 10 patents.

• Passed ISO9001:2000 quality system certificate.

• More than 10 types of machine and over 100 models for choose.

• Supply complete set of technology and equipment solution.

• We can design and manufacture all kinds of concrete forming equipment according to customers' demands. Meanwhile we can even more provide our customers a complete set of technology and solution for all producing flow.

8. Our Service:

• We supply the technical supporting all the time.

• We supply one year warranty for whole machine.

• We supply free quick wear parts.

• We supply low charge continue maintenance when warranty is expired.

• We supply free training to end-users

- Q:Payback: Quebec, Inc., is purchasing machinery at a cost of $3,768,966. The company expects, as a result, cash flows of $979,225, $1,158,886, and $1,881,497 over the next three years. What is the payback period?

- Plugging okorder /

- Q:Efficency , Cost-effective

- PHARMACO okorder /

- Q:How to make full use of slaughtering machinery scalding pool?thanks?

- Blowers scalding hot pool outside the pool so water inrush current composition of poultry fulfill staggered through electromechanical effects of propeller pumping hot water pool outside it, for it is rinsed, so both ends of the local hot pools million drug is not easy too small, too small will be staggered friction temperature for poultry

- Q:A ers' wagesB.machineryC.trainingD.marketing

- B. machinery At the outset, the change was from a 'cottage industry' where skilled worked by hand created products in the home, being supplied materials by their investor boss. The machine that spins, or does anything else, creates far more output than the individual hand-worker could. But it also consolidates potentially illicit power into the hands of one or a few tsars of production; and it requires the legislature of a nation to think very seriously about non-fictional statements, value claims, working conditions, conditions of contract between investor and skilled workers, etc. None of this was done. So while some retraining took place so workers hired (for whatever reason good or bad) could use the new machines, the main investment was in the machines themselves. The automation made by the output cheaper goods abundantly available fairly rapidly; But in the absence of curbs on overpopulation, government regulation of non-fictional utterance and governance of potentially-harmful corporate crimes, the situation that was bettered by the introduction of automation also saw the laying of the groundwork for the present anti-capitalist, anti-secular and anti=individualist practices of public interest elected and appointed tsars and their corporate and financial power-stealing tsarist cronies.

- Q:Is machinery still being built?

- yes it is

- Q:what are the auxiliary machinery found in ships?

- Ships auxiliary machinery is EVERYTHING which is vital to the operation of the vessel apart from the main engines and in the case of steamers, the boilers. In addition to the boilers and propulsion machinery, the engine room also contains most of auxiliary machinery to run the rest of the ship's systems. Steam or diesel driven generators provide electricity for the ship's lights and motors. There are centrifugal separators for turbine gear oil on steam turbine propelled ship and for fuel oil on diesel ships. An electrical distribution panel to allow control of the ship's electrical systems. On diesel powered ships, there are air compressors and receivers for starting air for the main and auxiliary engines. Refrigerated ships have refrigerant compressors to maintain the temperature of the holds. There are also steam or electrically powered pumps for clearing the bilges, transferring ballast, pumping feed water, circulating cooling water, pumping cargo, etc. etc. etc. Outwith the engineroom there are winches and cranes for cargo handling, windlasses, mooring capstans and most importantly the steering gear.

- Q:What is the best way to develop abs quickly without using any machinery?

- Try okorder : Home workouts. do your ab workouts for atleast 15-20 minutes a day. Good luck on your exercising. i am on a exercise routine too. :). REMEMBER! Always stretch your muscles before attempting these activities!

- Q:Can the shears machine be processed?

- According to the classification of materials can be cut: metal sheet, non-ferrous metal sheet; with a certain strength and toughness of non-metallic materials such as plastics, polyurethane and so on.

- Q:green company purchased a piece of machinery on credit for 10,000.Briefly state how this transaction affect th?

- Green okorder

- Q:Have you ever driven heavy machinery like a fork lift?

- I never have personally, but I work with people who drive them everyday. I work in manufacturing. There's a little tug machine I drive sometimes but its simple and more like driving a car than a forklift.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Large-span Prestressed Concrete Hollow Core Slab Making Machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords