Automatic Precast Concrete Pillar Making Machine Prefab house

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Automatic Precast Concrete Pillar Making Machine Prefab house

1. Structure of Automatic Precast Concrete Pillar Making Machine Prefab house:

Automatic Precast Concrete Pillar Making Machine Prefab house is our special developed products as results of our engineers research, with which 60%steel material will be saved compared with traditional revolving die method .Efficiency can be improved 3 to 5 times compared with conical die method, these machine are easy for operation and convenient for maintenance, products from these machines are in good quality, smooth appearance and accurate in size.

2. Main Features of Automatic Precast Concrete Pillar Making Machine Prefab house:

• One machine can make one slab lower cost, high Wear-resistant, long service life.

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Simple structure, easy operate, less wear parts

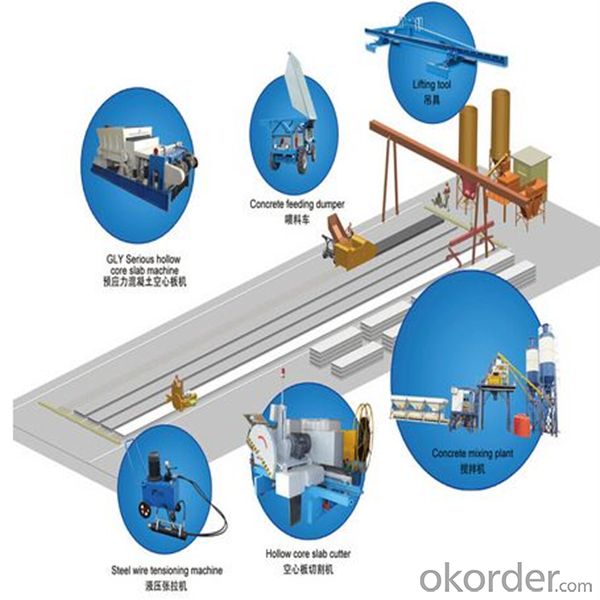

3. Automatic Precast Concrete Pillar Making Machine Prefab house Images:

4. Automatic Precast Concrete Pillar Making Machine Prefab house Specification:

Model no. | No. of holes | Dia. | No. and dia. of wires | Electric motor power(kw) | Vibrator Motor Power(kw) | Total Power (kw) | Max. span | Molding Speed(m/min) | Overall dimension (mm) | Weight (kg) |

60X120X140X4 | 1 | 30 | 5/5 | 4 | 1.5 | 5.5 | 3.5 | 1.3-1.5 | 2250×900×850 | 1000 |

60X130X150X4 | 1 | 30 | 6/5 | 4 | 1.5 | 5.5 | 4 | 1.3-1.5 | 2250×900×850 | 1000 |

70X140X160X4 | 1 | 30 | 8/5 | 4 | 1.5 | 5.5 | 4.5 | 1.3-1.5 | 2250×900×850 | 1050 |

70X150X170X2 | 1 | 30 | 8/5 | 3 | 1.5 | 4.5 | 4.7 | 1.3-1.5 | 2250×900×850 | 750 |

60X110X130X4 | 1 | 30 | 6/5 | 4 | 1.5 | 5.5 | 3.5 | 1.3-1.5 | 2250×900×850 | 950 |

Production Line Layout

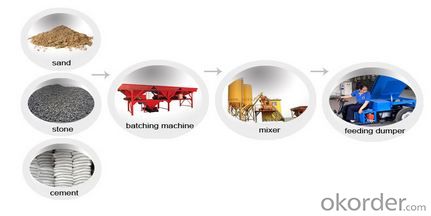

Production Process

Rebar tensioning

Raw materials preparing

Molding

Certificates

5. Packing & Delivery

• Wire cables are used for fastening the machine on the trailer or inside the container.

• Machine covered with plastic film.

• Machines can be packed in tarpaulin or wooden case according to customer’s needs.

6. Customers from All Over The World

7. FAQ:

We have organized several common questions for our clients, may help you sincerely:

• What information we need to confirm with you before send a formal offer?

What kind of slab you want to make, wall panel, roof panel, lintel or something else?

Do you have exact slab size (slab thickness and width)? If not, please tell us the slab span, we will give you suggestion.

• Have you use this kind of machine before?

Our machine is totally different from European machine. Please don’t follow their instructions.

• How long can we receive the product after purchase?

In the purchase of product, within 20 working days we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 35 working days can be served.

• What kind of machine do you have?

Our main products: large span GLY concrete hollow core slab machine, light - weight wall panel machine, lintel machine, column machine, hollow core slab cutting machine, concrete feeding dumper, high-strength steel wire tensioning machine, which amount to more than the types and more than four hundred standards. We can provide the whole plan and technology supporting for concrete precast component.

8. Our Service:

• We supply the technical supporting all the time.

• We supply one year warranty for whole machine.

• We supply free quick wear parts.

• We supply low charge continue maintenance when warranty is expired.

• We supply free training to end-users

- Q:i've been working out on my arms for 6 months now but can't seem to get any results on the sides of my upper arms.i'm not really skinny,i'm avarage body build but i have skinny arms.i can grow muscle on front and back of my arms,but not on the sides.what are some good exercises,exercise machinery or techniques i can use to target these areas?(and sorry i don't know the technical names for these muscles in the arm)

- are you referring to triceps? If so, do chair dips. side leaning dumbell raise, laying side tri rise. These are crucial for bigger arms. Triceps. Just look up shoulders and arms from p90x. it'll help you.

- Q:to other countries as another income stream. I already broker it in the USA. Is Exporting a good business?

- hg

- Q:I have a go cart with a 6.5 horsepower general machinery small engine. The engine starts right up first pull but as soon as I press the throttle, the engine dies. The only way to use it is if you start the engine with the throttle being pushed, but if you let it idle for about 10 seconds after that it dies. Whats going on here??? Any help would be greatly appreciated.

- clean carb...idles ok but given gas stalls....when u hit throttle u open letting in more air...not enough gas..

- Q:Metal materials commonly used in the processing methods which

- Metal materials commonly used in processing technology is divided into cold processing and hot processing, cold processing mainly refers to the mechanical processing such as milling machine drilling boring grinding, cold processing such as cold, cold bending, cold drawing, etc .; hot processing according to the use of different processes into casting

- Q:If the machinery that accomplishes X-chromosome dosage compensation in humans was defective (e.g., 1 protein was mutant), what do you expect the consequences would be? Choose one. a) no consequences b) XX embryos would not be viable c) XY embryos would not be viable d) both XX and XY embryos would not be viable

- B

- Q:Gain on sales of machinery would be recorded as what? Debit or Credit?

- Gain on sale of machinery is going to be a revenue account (hence credit to increase). The dollar amount of the gain would equal the difference between the book value of the machinery and the amount received for it. Debit 'Cash' for amount received, debit 'Accumulated Depreciation - Machinery' for the total amount that it has been depreciated, credit 'Machinery' for the original cost of it, and credit 'Gain on Sale of Machinery' for the amount that makes the journal entry be in balance.

- Q:Retired a piece of machinery that?

- Presented below are selected transactions at Ingles Company for 2008.Jan. 1Retired a piece of machinery that was purchased on January 1, 1998. The machine cost $62,000 on that date. It had a useful life of 10 years with no salvage value.June 30Sold a computer that was purchased on January 1, 2005. The computer cost $40,000. It had a useful life of 5 years with no salvage value. The computer was sold for $14,000.Dec. 31Discarded a delivery truck that was purchased on January 1, 2004. The truck cost $39,000. It was depreciated based on a 6-year useful life with a $3,000 salvage value.Journalize all entries required on the above dates, including entries to update depreciation, where applicable, on assets disposed of. Ingles Company uses straight-line depreciation. (Assume depreciation is up to date as of December 31, 2007.) (List multiple debit/credit entries in descending order of amount.)

- Q:Please introduce a link that explain these functions in a list or categorical. I would prefer new and interesting functions.Thank you

- Fluid okorder /

- Q:I am planning to setup a juice processing unit and therefore need help and info on the plant and machinery either on turnkey basis or upfront selling along with technology transfer.

- I okorder

- Q:I want to to start designing and building my own mechanics are there any books or dvds that I can buy or is there any online forums that could give me advice

- www.okorder

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Automatic Precast Concrete Pillar Making Machine Prefab house

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords