Industrial grade Good quality alumina oxide al2o3

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Industrial grade Good quality alumina oxide al2o3

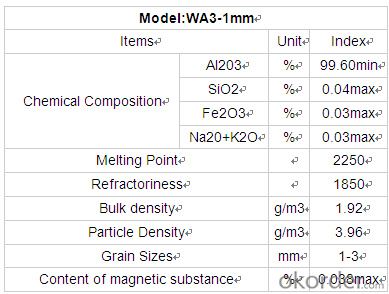

Specification:

High purity AL2O3 Aluminum Oxide/ Aluminum powder

Manufacturer

Superfine

Application of AL2O3

Aluminum Oxide for aluminum smelting, glass, ceramic industry etc.

Aluminum Oxide for refractory, coating, abrasive application.

Aluminum Oxide for electric basal plate, desiccating agent, chemical and pharmacy industry etc.

aluminum oxide property:

Soluble in water white solid. Odourless. Tasteless. Qualitative very hard. Easy absorption of moisture and not ChaoXie. Both sexes oxide, soluble in inorganic acid and alkaline solution, almost insoluble in water and the polar organic solvents. The relative density (d204) 4.0. Melting point about 2000 °C.

The physical and chemical analysis:

Main standard:

Alumina(industry grade) made by slkali-lime sintered,It is white powdered crystal with low assay of Ti, Mn, Zn, Cu, V, Zr, Cr, Li, Pb, B, P, etc.It is used in the production of fused salt eletrorefining aluminium, corundum eramics, refractories and other alumina chemical products.

Product Pictures:

If you’ve any enquiry please don’t hesitate to contact us!

- Q:What is neutral refractory? Can refractory suppliers tell the main components of it?

- // Baike? Url x3d CQ3i6_yUCWUMgk3aaRGGLURNtvKPl5IdZpj35Yvommk7Nyif0IJD-SkdIW29GCHwLpb9cT9Ii25GLcEJg-ZHcq "target x3d" _blank "x26gt; http://baike.baidu.baidu.

- Q:What are included in roof thermal insulation fireproofing material?

- Aluminium foil, bubble, aluminium foil/air bubbles/fireproofing aluminium foil thermal insulation material, fireproofing bubble thermal insulation material, fire?retardant thermal insulation material, thermal insulation construction materials, aluminum foil insulation material.

- Q:Which fireproofing materials factory is the best in Xiangyang?

- Of course, it is "Lvchuang Construction Energy Saving Engineering Co., Ltd." in Xuzhou, which main products are A-level fireproofing thermal insulation boards. It has many projects. B1-level fireproof materials are polyphenyl boards, extruded sheets, phenolic foam boards, Polyurethane board, sea capacity building energy efficiency module. Flame retardant has been added to the sea capacity building energy efficiency modules which has a B1-level fireproofing performance. You can also add expanded glazed hollow beads to them if you are worried about the security.

- Q:What are the uses of refractory materials of glass furnace?

- crown--high-purity silica bricks; wall--melting end 41# fused zirconia corundum bricks with no shrinkages(41% of zirconium, similarly hereinafter), cooling end 33# fused zirconia corundum bricks with no shrinkages; bottom--33# fused zirconia corundum bricks(with shrinkages); breastwork--33# fused zirconia corundum bricks(with shrinkages); port--33# fused zirconia corundum bricks(with shrinkages); regenerator chamber--the upper part is for magnesite-chrome bricks, the bottom part is for high-duty fireclay bricks; checker--the upper part is for high purity magnesia bricks, and the bottom part is for magnesite-chrome bricks; flue--clay bricks. This is the best configuration. If the funds are limited, the configuration can be lowered, for example, the wall will be changed to 38 #......

- Q:What does fire-resistant insulation coating have?

- Refractory thermal insulation material mainly refers to the inorganic thermal insulation material and composite thermal insulation material. According to the shape, it can be divided into: Finishing of fibrous shape, mineral?cotton, rock wool, glass wool, aluminum?silicate?wool, ceramic fiber, etc. Diatomaceous earth of microporous pile, calcium silicate, expanded perlite,expanded vermiculite,aerated concrete, etc. Foam glass of bubble shape, volcanic ash glass, foamed clay, foamed?concrete, gelatine powder polyphenyl granule heat insulating slurry of pasty form, etc. Their common feature is fire-retardant and firproof. It can be used in buildings with high requirements of fire?rating. Calcium silicate, aluminum silicate and asbestos can also be used for piping insulation of heat transport with high temperature.

- Q:Is there vermiculite in refractory?

- Foreign horticultural vermiculite includes four levels according to the diameter: 3 8mm is No. 1; 2 3mm No. 2, the most commonly used; 1 2mm to No. 3; 0.75 1mm to No. 4, suitable for seed germination. Vermiculite has strong water absorption capacity,

- Q:how long is the fire endurance of plasterboard?

- Plasterboard is non-flammable B1 level products. There are introductions in Fireproof Specification of National Standard Building Interior Decoration Design. Plaster board mounted on steel stud can be used as A level decoration materials. In accordance with the national fire safety rules on fire durance of walls and ceilings and other components, we can not simply say whether a piece of gypsum board can meet the requirements. In GB "gypsum board" it clearly states: Fireproof plasterboard can endure fire longer than 20minutes. Wherein Dragon brand fire-resistant gypsum board can endure fire longer than 40 mintues. Gypsum board is comprised of dry wall, steel stud and various auxiliary materials. the fireproof performance of the gypsum board system is relevant to the type, quality , layers of the gypsum board, quality of keel and installations, whether the rock wool is filled and its unit weight, the treatment of seaming and some minor joints.

- Q:Which region use more refractory?

- Tangshan of Hebei province, Jincheng of Shanxi province, Wuxi of Jiangsu province, Wuhan of Hubei province

- Q:What is the the best ratio of mortar in refractory cement?

- The ratio of refractory cement are: M10 the ratio of cement and mortar: cement: Sand= 346kg: 1631kg M7.5 ratio of cement and mortar: cement: Sand =274kg: 1631kg M5 The mix proportion of cement and mortar: cement: Sand = 209kg: 1631kg M10 mix proportion of composite mortar: cement: Sand: Lime =306kg: 1600kg: 29kg M7.5 mix proportion of composite mortar: cement: Sand: Lime =216kg: 1600kg: 64kg M5 The mix proportion of composite mortar: cement: Sand: Lime =205kg: 1600kg: 100kg

- Q:What are the characteristics of magnesium fireproof plate

- Features: Glass magnesium plate is high temperature resistant, sound absorbing, and capable of preventing water, pests, dampness, corrosion, poison, pollution. Paint can directly be applied to the surface of the plate. Air nails are usable for the plate, to which ceramic tile can also be applied with good pigmentation. The plate is easy to decorate, has high strength, good flexibility when bending, and can be nailed, sawed, glued It can also be made into thermal insulation materials with a variety of compround composite insulation plate. Characteristic: Magnesium plate glass is high temperature resistant, sound absorbing, and capable of preventing water, pests, dampness, corrosion, poison, pollution. Paint can directly be applied to the surface of the plate. Air nails are usable for the plate, to which ceramic tile can also be applied with good pigmentation High strength, flexibility when bending, convenient for decoration. It can be sawed, nailed, and glued.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Industrial grade Good quality alumina oxide al2o3

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords