Hydraulic Climbing Formwork Protection Panel System for Formwork

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Hydraulic Climbing Formwork Protection Panel Description

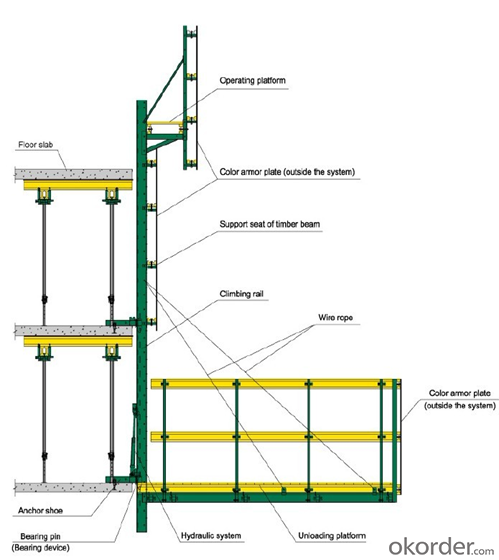

The climbing protection panel is enclosure for construction of high-rise buildings.The system has hydraulic system as its power, so it can climb up by itself. Cranes are not needed during the climbing. Thesystem can match loading platform, which is convenient for moving formwork and other materials to upper floor without disassembly.The construction efficiency will be increased highly. The climbing protection panel is an advanced, modern system which suits the demand of safety and civilization, widely used in construction.

2. Main Features of Hydraulic Climbing Formwork Protection Panel

- convenient for construction

- easy to control the quality

- easy, rapid and economical.

3. Hydraulic Climbing Formwork Protection Panel Specifications

Timber beam column formwork is used for the concrete pouring of square or rectangle column. The system has the same structure and similar connection type with wall formwork.

4. CMAX Hydraulic Climbing Formwork Protection Panel Images

5. FAQ of CMAX Hydraulic Climbing Formwork Protection Panel

1) What can we do for you?

- We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

- We can provide you the professional design team.

- We can provide fashionable and newest styles for you.

- We can design the artwork for you.

- Please feel free to customize.

2) What promises can be done by us?

- If interested in Timber-beam Formwork, please feel free to write us for any QUOTE.

- If printing required, please advise asap because the whole set need much more time to complete.

- Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about the package and shipping time?

- Packing: As Customer's Requirements

- Shipping: We have various shipping ways for our customers, such as express, by air/ sea etc.

- Shipping time: Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

- Q:How is the hydraulic support moving

- (1) before the shift frame, open the stent into the liquid valve, clean the frame of floating coal, floating gangue and other debris, or are not allowed to shift frame; also check the roof The situation, and found that the roof broken or pumping the phenomenon of the top of the row, to deal with and then move the shelves, to prevent the process of moving off the roof is too large and cause injury; and to check the front whether there are cables, pipes and other equipment, Clean up and then move the shelves; if you can not clean up the mark after the shelves, to be shut down after a comprehensive treatment. (2) when the shift frame when the first column, so that the top beam from the top plate, stop the column quickly shift frame; for broken roof to allow "rub top shift" or "with pressure shift frame" Should be out of the metal net to avoid tearing the net. (3) after the shift must be arranged neatly formed a straight line; in the roof before and after the top are connected, the appropriate adjustment of the balance jack, so that the bracket to achieve the best support effect.

- Q:Is the scaffolding scaffolding?

- Climbing frame, also known as lifting frame, according to its power source can be divided into hydraulic, electric, human hand pull and other major categories. It is developed in recent years, a new scaffolding system, mainly used in high-rise shear wall real estate. It can climb up or down along the building.

- Q:Climbing several, how is it running? And how much is the rental fee? Please explain in detail master! Thank you!

- Climbing frame, also known as lifting frame, according to its power source can be divided into hydraulic, electric, human hand pull and other major categories. It is developed in recent years, a new scaffolding system, mainly used in high-rise shear wall real estate. It can climb up or down along the building. This system makes the scaffolding technology completely changed: one is not to turn the shelves; the second is to remove the scaffolding of the dismantling process (after the assembly has been used to complete the construction), and not subject to height restrictions on the building, a great savings in manpower And material. And in the security point of view for the traditional scaffolding has a greater improvement. In the high-rise buildings with great development advantages.

- Q:Climbing and floor scaffolding advantages and disadvantages

- The bolt tightening torque should not be less than 40N · m, and should not be greater than 65N · m; [1] 2) The bar at the node is eccentric, 3) The connection quality of the fastener joints is significantly affected by the quality of the fastener itself and the operation of the workers. (3) The connection quality of the fastener joints is significant.

- Q:The difference between climbing and sliding mode

- The main difference between climbing and sliding mode (simple distinction, see below for details): Slipform: Increases the overall scale of the mold and the concrete in contact with each other. When the sliding mold is raised, the concrete in the upper part of the template is just under water, and the concrete in the lower part is near the initial condensed state, and the strength of the concrete is only 0.2 ~ 0.4Mpa. Climbing mode: the rise, the template has been off the concrete, then the concrete strength is greater than 1.2Mpa, the template is not friction with the concrete. Detailed distinction: Slip mode: cement concrete pouring used in a template, it can be along the horizontal direction, the slope direction or vertical direction gradually sliding, so that the side of the paused, side stripping, is an economical and advanced method, Known as sliding mode construction. The concrete used is hard thick concrete, or when the template slips, the edges of the concrete are prone to collapse. High-rise buildings, if the site stacking conditions are limited, the use of sliding mode is better, and the construction speed, reduce the template loss rate. But for the special wall of the building is not suitable for more. Climbing template: climbing template is attached to the building structure, with the structure of the construction and layer by layer of a template, when the structure of concrete to achieve demoulding strength and stripping, the template does not fall, relying on mechanical equipment and support the template And climbing up the device to climb up a layer, positioning fastening, repeated cycle construction. Climbing is an advanced template construction technology for cast-in-place reinforced concrete structures for high-rise buildings or towering structures.

- Q:What is a climbing frame?

- Climbing frame, also known as lifting frame, according to its power source can be divided into hydraulic, electric, human hand pull and other major categories. It is developed in recent years, a new scaffolding system, mainly used in high-rise shear wall real estate. It can climb up or down along the building. This system makes the scaffolding technology completely changed: one is not to turn the shelves; the second is to remove the scaffolding of the dismantling process (after the assembly has been used to complete the construction), and not subject to height restrictions on the building, a great savings in manpower And material. And in the security point of view for the traditional scaffolding has a greater improvement. In the high-rise buildings with great development advantages.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hydraulic Climbing Formwork Protection Panel System for Formwork

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords