Climbing Platform CP190 for High Building Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 80000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

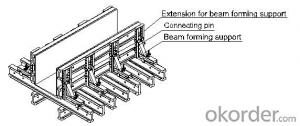

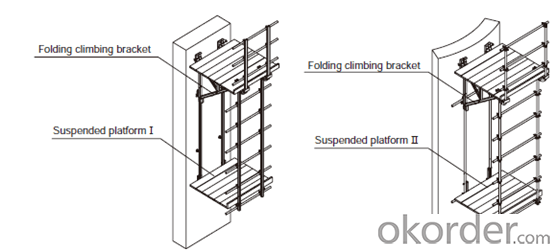

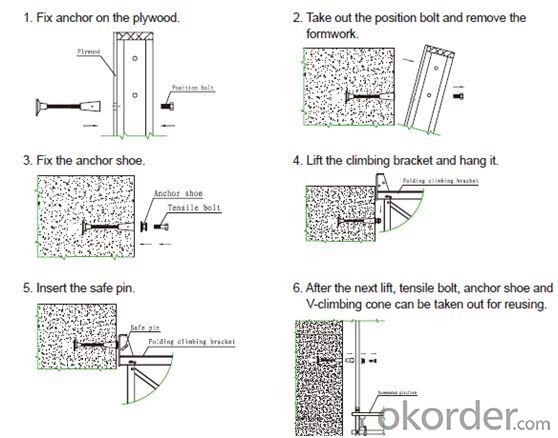

1. Structure of Climbing Platform CP 190

Climbing bracket CP190 is mainly used as operating platform during construction. It can be used on the vertical wall and arced wall. The bracket hang on the anchor system and all the load are supported by anchor system. It’s convenient to assemble and dismantle, the construction is easy, rapid and safe.

2. Main Features of Plastic concrete formwork Accessories

-flexibly sed in vertical and arced wall.

-convenient to assemble and dismantle

-easy, rapid and safe

3. Climbing Platform CP 190 images

4: Climbing Platform CP 190 Specifications

5. FAQ of Climbing Platform CP 190

1) What can we do for you?

.We can ensure the quality of Climbing Platform CP 190 images panel and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your projects.

2) What promises can be done by us?

. please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issues.

- Q:How is the hydraulic support moving

- The hydraulic support is connected to the scraper conveyor by pushing the lever and the crosshead: pushing the jack extension, pushing the lever out, pushing the scraper conveyor forward a step, which is called pushing; pushing the jack to take, The board conveyor reacts on the stand, driving the carriage forward by a step, which is called a shift frame.

- Q:Is the scaffolding scaffolding?

- This system makes the scaffolding technology completely changed: one is not to turn the shelf, the second is to remove the scaffolding of the dismantling process (after assembly has been used to complete the construction), and not subject to height restrictions on the building, a great savings in manpower And material. And in the security point of view for the traditional scaffolding has a greater improvement. In the high-rise buildings with great development advantages.

- Q:Climbing several, how is it running? And how much is the rental fee? Please explain in detail master! Thank you!

- Set the mounting platform --- Place the base, install the rails, assemble the horizontal truss parts - connect the beams to the rails with bolts and fasten the main frame to the beams - On the beam - the installation of wall-mounted device, the frame unloading to the guide seat --- with the structure connected to the elevated body, erected scaffolding, laying the middle layer or temporary scaffolding --- and the building structure to do temporary frame Pull the connection, hanging out the top of the safety net --- installed after the third beam, the installation of lifting seat and a layer with a wall guide block --- then the main frame of the main frame, the frame erected to the design height, Laying the top scaffolding plate, foot plate --- laying the bottom of the safety net and scaffolding, the production of flap - the upper frame and the structure of the effective pull-pull (pull-pull spacing of not more than 6m) --- hanging outside the row of dense security To the top of the frame --- the anti-fall boom inserted into the base anti-fall device, install the lifting wire rope --- placed electric control cabinet, distribution cable, install electric hoist, wiring, commissioning electrical system --- preload electric gourd, inspection and acceptance, with removal of the upper frame structure then pull, lift one synchronization --- fully installed, into Upgrade cycle

- Q:Climbing and floor scaffolding advantages and disadvantages

- The bolt tightening torque should not be less than 40N · m, and should not be greater than 65N · m; [1] 2) The bar at the node is eccentric, 3) The connection quality of the fastener joints is significantly affected by the quality of the fastener itself and the operation of the workers. (3) The connection quality of the fastener joints is significant.

- Q:The difference between climbing and sliding mode

- Sliding mold is pouring process, the concrete has not yet solidified, it will continue to lift or move the template, so that the formation of the template and pouring concrete between the relative sliding climbing mold is pouring a template, to enhance the climbing frame, and then install A template

- Q:What is a climbing frame?

- Taosheng Technology TOSUN as the leading research and development, production, sales, leasing and construction units in China, is committed to providing customers with comprehensive construction safety protection solutions.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Climbing Platform CP190 for High Building Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 80000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products