Hydraulic Auto-climbing Formwork from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

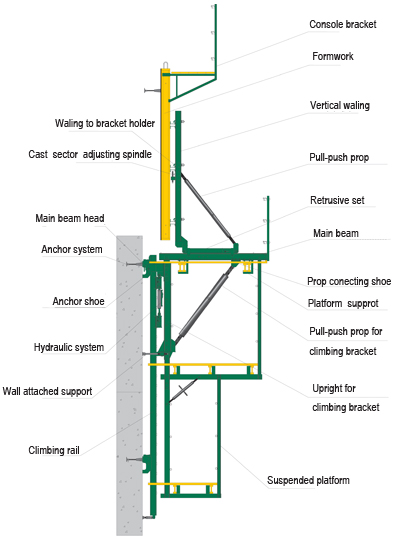

Product Introduction

The power of the auto-climbing formwork is the hydraulic system, which includes the oil cylinder and commutators. Through the functioning of hydraulic system, the steel rail and bracket can climb up alternately,The commutators can control the climbing of the climbing rail and the bracket. The steel rail and the bracket can inter-climbing, so the whole system will climb up steadily. Cranes are not needed during the construction. It' s easy to operate, and climbing is fast and safe.

Product Characteristics

1. Perfect load bearing anchor system.

2. Crane-independent

3. One oil cylinder unit can lift 50KN.

4. The QPMX-50 system can climb not only vertically but also slantwise, and the forward or backward inclination can be up to 18 degrees.

5. The system can climb up wholly or separately. The climbing process is steady, synchronous and safe.

6 .The bracket does not come back to the ground until construction work is finished, and spacing for work is reduced while the bumping damage is almost completely prevented, especially for the plywood.

7.The error of structure construction is tiny and easy to correct.

8.The formwork can climb up by itself and cleaning work can be done in situ. The number of crane lifts are greatly reduced.

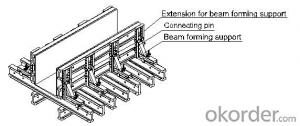

Climbing Process Introduction

1.Set up the formwork by wall-through tie-rods and pull-push props, embed anchors and do the first concrete pouring.

2. Remove the formwork after the first pouring and fix anchor shoes on the finished wall, lift the brackets and formwork to the right position, match the formwork and do the second pouring.

3.Lift formwork and brackets to the higher floor; fix climbing rail and hydraulic system.

4.Match the formwork to the right position and do the third pouring.

5.Strip the formwork and fix anchor shoes on the finished wall, then let the climbing rails climb.

6. Brackets climb up to the right position, then install suspended platform.

7.Match the formwork, do the concrete pouring, and proceed into the standard climbing stage.

- Q:How is the hydraulic support moving

- (1) before the shift frame, open the stent into the liquid valve, clean the frame of floating coal, floating gangue and other debris, or are not allowed to shift frame; also check the roof The situation, and found that the roof broken or pumping the phenomenon of the top of the row, to deal with and then move the shelves, to prevent the process of moving off the roof is too large and cause injury; and to check the front whether there are cables, pipes and other equipment, Clean up and then move the shelves; if you can not clean up the mark after the shelves, to be shut down after a comprehensive treatment. (2) when the shift frame when the first column, so that the top beam from the top plate, stop the column quickly shift frame; for broken roof to allow "rub top shift" or "with pressure shift frame" Should be out of the metal net to avoid tearing the net. (3) after the shift must be arranged neatly formed a straight line; in the roof before and after the top are connected, the appropriate adjustment of the balance jack, so that the bracket to achieve the best support effect.

- Q:Is the scaffolding scaffolding?

- The difference between scaffolding and scaffolding is that the commonly used scaffolding is always erected from below, and the climbing is followed by the rise of the building, that is, the map made upstairs, and the common thing is that everyone belongs to Scaffolding and the like

- Q:Climbing several, how is it running? And how much is the rental fee? Please explain in detail master! Thank you!

- Set the mounting platform --- Place the base, install the rails, assemble the horizontal truss parts - connect the beams to the rails with bolts and fasten the main frame to the beams - On the beam - the installation of wall-mounted device, the frame unloading to the guide seat --- with the structure connected to the elevated body, erected scaffolding, laying the middle layer or temporary scaffolding --- and the building structure to do temporary frame Pull the connection, hanging out the top of the safety net --- installed after the third beam, the installation of lifting seat and a layer with a wall guide block --- then the main frame of the main frame, the frame erected to the design height, Laying the top scaffolding plate, foot plate --- laying the bottom of the safety net and scaffolding, the production of flap - the upper frame and the structure of the effective pull-pull (pull-pull spacing of not more than 6m) --- hanging outside the row of dense security To the top of the frame --- the anti-fall boom inserted into the base anti-fall device, install the lifting wire rope --- placed electric control cabinet, distribution cable, install electric hoist, wiring, commissioning electrical system --- preload electric gourd, inspection and acceptance, with removal of the upper frame structure then pull, lift one synchronization --- fully installed, into Upgrade cycle

- Q:Climbing and floor scaffolding advantages and disadvantages

- Climbing frame, also known as lifting frame, according to its power source can be divided into hydraulic, electric, human hand pull and other major categories. It is developed in recent years, a new scaffolding system, mainly used in high-rise shear wall real estate. It can climb up or down along the building. This system makes the scaffolding technology completely changed: one is not to turn the shelf; the second is to remove the scaffolding disassembly process (after assembly has been used to complete the construction), and not subject to height restrictions on the building, a great savings in manpower And material. And in the security point of view for the traditional scaffolding has a greater improvement. In the high-rise buildings with great development advantages.

- Q:The difference between climbing and sliding mode

- The main difference between climbing and sliding mode (simple distinction, see below for details): Slipform: Increases the overall scale of the mold and the concrete in contact with each other. When the sliding mold is raised, the concrete in the upper part of the template is just under water, and the concrete in the lower part is near the initial condensed state, and the strength of the concrete is only 0.2 ~ 0.4Mpa. Climbing mode: the rise, the template has been off the concrete, then the concrete strength is greater than 1.2Mpa, the template is not friction with the concrete. Detailed distinction: Slip mode: cement concrete pouring used in a template, it can be along the horizontal direction, the slope direction or vertical direction gradually sliding, so that the side of the paused, side stripping, is an economical and advanced method, Known as sliding mode construction. The concrete used is hard thick concrete, or when the template slips, the edges of the concrete are prone to collapse. High-rise buildings, if the site stacking conditions are limited, the use of sliding mode is better, and the construction speed, reduce the template loss rate. But for the special wall of the building is not suitable for more. Climbing template: climbing template is attached to the building structure, with the structure of the construction and layer by layer of a template, when the structure of concrete to achieve demoulding strength and stripping, the template does not fall, relying on mechanical equipment and support the template And climbing up the device to climb up a layer, positioning fastening, repeated cycle construction. Climbing is an advanced template construction technology for cast-in-place reinforced concrete structures for high-rise buildings or towering structures.

- Q:What is a climbing frame?

- Climbing frame, also known as attached lift scaffolding, the equipment and equipment is the rapid development of the beginning of this century, a new scaffolding technology, construction technology in China has an important impact. It will be high operations into a low operation, the floating operations into the frame internal operations, with significant low-carbon, high-tech content and more economical, more secure, more convenient and so on.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hydraulic Auto-climbing Formwork from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords