Hot Rolled Mild Steel Plate JIS SS400 Carbon Steel Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Steel sheet, steel plate, mild steel sheet, carbon steel sheet

Size | Thickness:2.0-200mm |

Application | Steel plates are widly used as boiler plate, container plate, flange plate and ship plate, and also widly used in building construction. The size of steel plate can be made according to clients requirements. |

Packing | In bulk or as required |

| Delivery time | Within 10-25 days after order confirmed and L/C received |

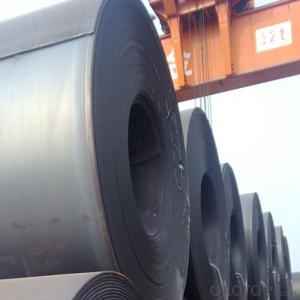

Workshop Show

Shipping

1. FedEx/DHL/UPS/TNT for samples, Door-to-Door;

2. By Air or by Sea for batch goods, for FCL; Airport/ Port receiving;

3. Customers specifying freight forwarders or negotiable shipping methods!

Delivery Time: 3-7 days for samples; 5-25 days for batch goods.

Package Informations

1) EXPORT, In 20 feet (GW 25 ton) or 40 feet Container (GW 25 ton)

2)as customer's requirement

Why choose us?

(1) The leading exporter in China special steel industry.

(2) Large stocks for various sizes, fast delivery date.

(3) Good business relationship with China famous factories.

(4) More than 7 years steel exporting experience.

(5) Good after-sales service guarantee.

- Q:What are the different surface finishing techniques used for special steel?

- There are several surface finishing techniques used for special steel, including electroplating, passivation, pickling, and powder coating. Electroplating involves depositing a thin layer of metal onto the steel surface to enhance its appearance and provide corrosion resistance. Passivation is a chemical process that removes surface contaminants and forms a protective oxide layer on the steel, preventing corrosion. Pickling involves using acid solutions to remove surface impurities and oxide layers, resulting in a clean and smooth surface. Powder coating is a technique where a dry powder is applied electrostatically to the steel surface and then cured under heat, creating a durable and decorative coating.

- Q:How does special steel contribute to reducing product rejection rates?

- Special steel contributes to reducing product rejection rates by offering superior strength, durability, and corrosion resistance. It enables manufacturers to produce high-quality products that meet stringent specifications and standards. Special steel's precise composition and unique properties enhance the performance and reliability of the end products, reducing the chances of defects, failures, and rejections.

- Q:How does special steel contribute to reducing product weight?

- Special steel contributes to reducing product weight through its unique properties such as high strength, durability, and lightweight composition. By using special steel in the manufacturing process, designers can optimize the strength-to-weight ratio of the product, allowing for thinner and lighter components without compromising on performance or safety. This reduction in weight not only enhances the efficiency and performance of the product but also reduces material and transportation costs, making it a valuable solution in various industries.

- Q:What are the different heat treatment processes for special steel?

- Some of the different heat treatment processes for special steel include annealing, quenching and tempering, hardening, case hardening, and precipitation hardening.

- Q:How does special steel contribute to the manufacturing of precision instruments?

- Special steel plays a crucial role in the manufacturing of precision instruments. Its unique characteristics and properties make it an ideal material choice for these applications. Firstly, special steel offers exceptional strength and durability, allowing precision instruments to withstand extreme conditions, heavy loads, and repetitive use. This ensures the longevity and reliability of these instruments, which is vital in critical industries such as aerospace, automotive, and medical. Moreover, special steel has excellent corrosion resistance, preventing the instruments from deteriorating over time. This is especially important for precision instruments that are exposed to various elements, chemicals, or moisture during their operation or storage. Special steel also provides high thermal stability, enabling precision instruments to maintain their accuracy in different temperature environments. This is vital for instruments that are used in industries where temperature fluctuations can affect their performance, such as laboratories or manufacturing plants. Additionally, special steel can be customized and tailored to meet specific design requirements. It can be easily machined, formed, or welded into intricate shapes and parts, allowing manufacturers to create precision instruments with complex geometries and tight tolerances. This level of precision is crucial for instruments used in fields like metrology, microscopy, or nanotechnology. Furthermore, special steel offers excellent magnetic properties, which can be advantageous for precision instruments that rely on magnetic fields for their operation. This includes instruments like magnetic resonance imaging (MRI) machines, compasses, or magnetometers. In conclusion, special steel contributes significantly to the manufacturing of precision instruments by providing strength, durability, corrosion resistance, thermal stability, customization options, and magnetic properties. These characteristics ensure the performance, accuracy, and longevity of precision instruments, making them indispensable in various industries.

- Q:What are the applications of tool steel?

- Tool steel is widely used in various applications due to its exceptional hardness, wear resistance, and ability to retain sharp edges. It is commonly utilized in the manufacturing of cutting tools such as drills, saw blades, and milling cutters. Additionally, tool steel finds applications in the production of molds for plastic injection or die casting, as well as in the manufacturing of punches, dies, and shears used in metalworking processes. Its high strength and heat resistance also make it suitable for applications in the aerospace and automotive industries, where it is utilized in components like engine valves, gears, and shafts.

- Q:Can special steel be used for making electronics components?

- Indeed, electronics components can be manufactured using special steel. This term refers to a particular type of steel that has been meticulously designed and fabricated to possess distinct properties and characteristics that render it suitable for a wide range of applications, including electronics. Within the realm of electronics manufacturing, special steel finds utility in the creation of various components such as connectors, springs, contacts, and other parts that necessitate exceptional strength, durability, and resistance to corrosion and wear. These attributes are vital in ensuring the dependable performance and long lifespan of electronic devices. Furthermore, special steel also offers remarkable thermal conductivity, electromagnetic shielding, and magnetic properties, which are critical in specific electronic applications. For instance, in the production of transformers, special steel laminations are employed to minimize energy loss and enhance efficiency. Moreover, special steel can be customized to meet the specific requirements of different electronic components. For example, certain grades of stainless steel can be utilized to fabricate components that must endure harsh environmental conditions or come into contact with corrosive substances. Overall, the utilization of special steel in electronics manufacturing presents a viable solution for producing components that can meet the exacting performance standards of contemporary electronic devices.

- Q:How does special steel contribute to the strength of structures?

- Special steel contributes to the strength of structures by providing enhanced properties such as high tensile strength, durability, and resistance to corrosion. This type of steel is specifically engineered to withstand heavy loads, extreme conditions, and harsh environments. Its superior strength allows for the construction of structures that can support more weight, withstand greater pressures, and resist deformation. Whether used in buildings, bridges, or machinery, special steel plays a vital role in ensuring the structural integrity and longevity of various constructions.

- Q:How does special steel contribute to reducing product downtime due to repairs?

- Special steel contributes to reducing product downtime due to repairs by offering increased strength, durability, and resistance to wear and tear. With its unique properties, special steel can withstand harsh conditions and heavy usage, resulting in longer-lasting and more reliable products. This reduces the frequency and duration of repairs, minimizing the downtime experienced by the product and ultimately leading to increased productivity and efficiency.

- Q:How does special steel comply with international standards?

- Special steel, specifically designed and manufactured to possess exceptional properties and performance, undergoes a rigorous process to ensure its quality and conformity to established norms. To begin with, adherence to international standards in the production of special steel is achieved through the meticulous selection of raw materials. The composition and quality of these materials are carefully controlled and tested to meet the specifications outlined by international standards organizations. This guarantees that the resulting special steel is of the desired quality and possesses the necessary mechanical properties. In addition, standardized production processes are followed by special steel manufacturers. These processes are designed in accordance with international guidelines and standards to ensure consistency and traceability. Through the use of advanced technologies and quality control measures, manufacturers can monitor and control every stage of production, from melting and casting to rolling and heat treatment. This guarantees that the final product meets the required standards in terms of chemical composition, mechanical properties, and dimensional tolerances. Moreover, stringent testing and inspection procedures are conducted to validate the compliance of special steel with international standards. Certified laboratories and independent third-party agencies perform various destructive and non-destructive testing methods, such as ultrasonic testing, hardness testing, and microstructure analysis. These tests ensure unbiased and accurate results. Furthermore, special steel manufacturers often have their production processes and quality management systems audited and certified by recognized bodies, like ISO, to demonstrate their commitment to compliance with international standards. It is also important to note that special steel manufacturers actively participate in international standardization committees, such as ASTM International and ISO. By engaging in these committees, they contribute to the development and revision of international standards, ensuring that their products remain up to date and aligned with the latest industry requirements. In conclusion, special steel complies with international standards through careful raw material selection, adherence to standardized production processes, rigorous testing and inspection, and active participation in international standardization committees. By following these measures, special steel manufacturers demonstrate their dedication to producing high-quality products that meet the strict requirements of international standards.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Rolled Mild Steel Plate JIS SS400 Carbon Steel Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords