Miniature Ball Bearings Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50MT m.t.

- Supply Capability:

- 500000TONS/YEAR m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Miniature Ball Bearings Steel

1. Dimensional sizes: Thickness: 14~100mm.Length:3000~5800mm,Diameter :14-500mm

2.Chemical composition: C=0.96~1.05,Si=0.15~0.35,Mn=0.25~0.45,Cr=1.4~1.65,

P≤0.025,S≤0.025,Ni≤0.22,Cu≤0.20,Mo≤0.08

3. Grade: SAE51200/ GCr15 / 100cr6

4. Heat Treatment:

Soft annealing: heat to 680-720°C, cool slowly.

Hardness after annealing: Max. 241 HB

Hardening: 820 - 850 °C

Normalizing temperature: 840-880°C

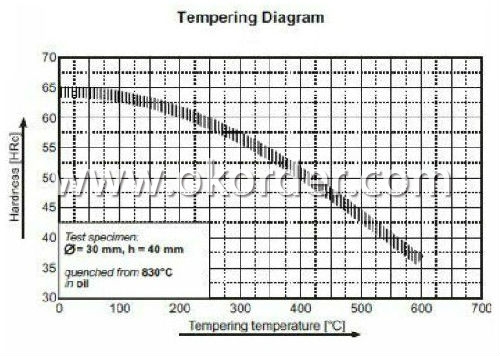

Tempering: 540-680°C

5. Surface requirements: Black, grinding, bright, polish

6. Payment terms: 20% deposit, balance against L/C at sight or T/T.

Usage & Applications of Miniature Ball Bearings Steel

Miniature ball bearings are machinery components, which comprise an outer ring, inner ring, balls, retainers, shields and snap rings. High quality through hardened bearing steel improves reliability. High grade balls have improved roundness and finish to reduce vibration and noise. Super finished raceways to reduce friction, vibration and noise resulting in increased bearing life and reduced maintenance cost. Proven seal solutions effectively retain lubricant and exclude contamination from moisture, dust, and dirt which extends bearing life and reduces maintenance cost. Premium grease reduces noise, vibration and meets high temperature application requirements which extend bearing life. Bearings available 100% noise tested on state-of the art equipment to meet Electric Motor OEM low noise expectations. Product tolerances exceed bearing industry standards to allow for global interchangeability.

Packaging & Delivery of Miniature Ball Bearings Steel

10 pieces in one plastic tube, 10 tubes in one paper box or as customer required

Delivery time: 20 days after order confirmed.

Samples Policy: please arrange the sample cost and freight or freight collected. We will reduce this part expense from the total value of our first order.

Note:

1. According to national standard (GB) for our products, if not, supply according to national standards (GB) or agreement.

2. We can not only provide electric furnace +LF+VD and electro-slag re-melting (ESR)steel forging materials, but also forging products of piece, bar, etc.

3. Our company is equipped with roll equipment and can provide our customers with roll billets or finished.

4. Please send us your detailed specifications when inquire. We will reply to you ASAP.

- Q:What are the safety measures taken during the production of special steel?

- To ensure the safety and wellbeing of workers and reduce potential hazards, various safety measures are taken during the production of special steel. These measures encompass the following: 1. Personal Protective Equipment (PPE): All workers involved in special steel production must wear appropriate PPE, including safety helmets, goggles, gloves, and protective clothing. This safeguards them from injuries, burns, and exposure to hazardous substances. 2. Training and Education: Workers undergo comprehensive training and education on safe work practices and procedures. They gain knowledge about the potential hazards associated with special steel production and receive training on the proper handling of equipment and materials. 3. Risk Assessments: Regular risk assessments are conducted to identify potential hazards and evaluate the level of risk associated with each task. This facilitates the implementation of control measures to mitigate risks and prevent accidents. 4. Machinery and Equipment Safety: All machinery and equipment used in the production process are meticulously maintained and regularly inspected to ensure optimal working conditions. Safety features, such as emergency stop buttons and guards, are installed to prevent accidents and injuries. 5. Ventilation and Exhaust Systems: Given the high temperatures and use of chemicals in special steel production, ventilation and exhaust systems are installed to eliminate harmful fumes and gases from the work environment. This ensures a safe and healthy atmosphere for workers. 6. Fire Prevention: To minimize the risk of fire accidents, fire prevention measures are implemented, including the installation of fire alarms, extinguishers, and sprinkler systems. Workers are also trained on fire safety protocols and evacuation procedures. 7. Emergency Response Plans: Comprehensive emergency response plans are developed and communicated to all workers. These plans outline the steps to be taken in the event of accidents, fires, or other emergencies, ensuring a swift and organized response. 8. Regular Safety Inspections: Safety professionals conduct regular inspections to identify any potential safety hazards or non-compliance with safety protocols. Any issues or deficiencies are promptly addressed to maintain a safe working environment. By implementing these safety measures, special steel production can be carried out in a controlled and safe manner, safeguarding workers and minimizing the risk of accidents or injuries.

- Q:How does special steel behave under different types of loading conditions?

- Special steel, also known as alloy steel, exhibits unique behavior under different types of loading conditions. It is specifically designed to possess exceptional mechanical properties, making it suitable for a wide range of applications where high strength, toughness, and resistance to wear or corrosion are required. Under tension loading, special steel demonstrates excellent tensile strength and ductility, enabling it to withstand pulling forces without easily fracturing. This property makes it ideal for applications where components are subjected to pulling or stretching forces, such as cables, structural elements, or automotive parts. When subjected to compressive loading, special steel showcases its exceptional compressive strength, allowing it to withstand forces that tend to squeeze or press it together. This makes it suitable for applications like hydraulic cylinders, crankshafts, or flanges, where resistance to compression is crucial. In terms of bending or flexural loading, special steel exhibits remarkable flexibility without losing its strength, enabling it to withstand repeated bending without deformation or failure. This property is particularly useful in applications involving springs, suspension systems, or beams subjected to dynamic loads. Special steel also demonstrates excellent fatigue resistance, which means it can withstand cyclic loading or repeated stress without failure. This property is crucial in applications subjected to continuous or repetitive loading, such as turbine blades, gears, or axles. Moreover, special steel can effectively handle impact loading, as it possesses high toughness and impact resistance. This makes it suitable for applications where sudden shocks or impacts are expected, such as hammer heads, drill bits, or armor plating. In terms of temperature loading, special steel retains its mechanical properties even at high temperatures due to its excellent heat resistance. This property makes it suitable for applications exposed to extreme heat or thermal cycling, such as turbine components, exhaust systems, or molds used in metal casting. In summary, special steel behaves differently under various loading conditions, adapting its mechanical properties to meet the specific requirements of each application. Its unique combination of strength, toughness, ductility, and resistance to wear or corrosion make it a versatile material capable of withstanding different types of loading conditions.

- Q:What are the challenges in forging special steel?

- Forging special steel poses several challenges due to its unique composition and properties. Firstly, special steels often have high carbon content, making them harder to forge compared to lower carbon steels. The high carbon content increases the risk of cracking and requires careful temperature control during the forging process to prevent metallurgical issues. Secondly, special steels may contain alloying elements like chromium, molybdenum, or nickel, which enhance their specific properties. However, these alloying elements can also contribute to increased hardness and brittleness, making the forging process more challenging. Special attention must be given to heat treatment procedures to achieve the desired balance of strength and toughness. Furthermore, the complex internal structure of special steels, including the presence of inclusions and segregation, can further complicate the forging process. These internal defects can lead to uneven deformation, inadequate mechanical properties, or even failure during forging, necessitating meticulous quality control measures. Lastly, the cost of special steel materials is generally higher than that of regular steels, making any errors or wasted materials during the forging process more significant. The need for specialized equipment, skilled labor, and stringent quality assurance further adds to the challenges associated with forging special steel. Overall, forging special steel demands expertise, precision, and meticulous control of various parameters to ensure the desired mechanical properties and quality of the final product.

- Q:Can special steel be used in the wind turbine manufacturing industry?

- Yes, special steel can be used in the wind turbine manufacturing industry. Special steel, such as high-strength or corrosion-resistant alloys, is often used in the construction of wind turbine components due to its durability, strength, and resistance to harsh environmental conditions. These specialized steel alloys help ensure the longevity and performance of wind turbines in the renewable energy industry.

- Q:What are the main characteristics of alloy steel?

- Alloy steel is a type of steel that is made by adding certain elements, such as chromium, nickel, or molybdenum, to iron. These additional elements give alloy steel its unique properties and characteristics. Some of the main characteristics of alloy steel include: 1. High strength: Alloy steel is known for its exceptional strength. The addition of alloying elements enhances the steel's ability to withstand high pressures and heavy loads, making it ideal for applications that require a strong and durable material. 2. Hardness: Alloy steel is also known for its hardness. It has a higher level of hardness than regular carbon steel, which makes it resistant to wear, abrasion, and deformation. This characteristic makes alloy steel suitable for applications where resistance to impact or wear is crucial, such as in the manufacturing of cutting tools or machinery parts. 3. Corrosion resistance: Depending on the specific alloying elements added, alloy steel can exhibit excellent resistance to corrosion. Chromium, for example, is commonly added to alloy steel to create stainless steel, which is highly resistant to rust and corrosion. This characteristic makes alloy steel a preferred material in industries where exposure to moisture or corrosive environments is common. 4. Heat resistance: Alloy steel is known for its ability to withstand high temperatures without losing its strength or structural integrity. The addition of elements like nickel, molybdenum, or vanadium enhances the steel's ability to resist thermal expansion, oxidation, and softening at elevated temperatures. This characteristic makes alloy steel suitable for applications in the aerospace, automotive, and power generation industries. 5. Versatility: Alloy steel is a versatile material that can be easily customized to meet specific requirements. By varying the composition and proportions of alloying elements, manufacturers can create alloy steel with a wide range of properties, such as improved ductility, toughness, or electrical conductivity. This versatility allows alloy steel to be used in various industries, including construction, manufacturing, and engineering. Overall, the main characteristics of alloy steel are high strength, hardness, corrosion resistance, heat resistance, and versatility. These properties make alloy steel a preferred choice for a wide range of applications that require a strong, durable, and reliable material.

- Q:What are the specific requirements for special steel used in the marine shafting industry?

- The marine shafting industry has specific requirements for special steel, which are as follows: 1. Corrosion Resistance: The steel used in marine shafting must possess a high resistance to corrosion, as it is exposed to harsh marine conditions. It should be able to withstand saltwater, humidity, and other corrosive elements without deteriorating. 2. Strength and Toughness: Marine shafting steel should have high strength and toughness to withstand the heavy loads and vibrations experienced in marine operations. It should be able to handle continuous stress and dynamic loads without failing or deforming. 3. Fatigue Resistance: The steel used in marine shafting should have excellent fatigue resistance to endure the cyclical loading during operation. It should be able to withstand millions of load cycles without developing cracks or fractures. 4. Dimensional Stability: Special steel used in marine shafting must maintain dimensional stability to ensure accurate alignment and fit within the machinery. It should have minimal dimensional changes under varying temperature and humidity conditions to preserve the integrity of the shaft system. 5. Machinability: The steel used in marine shafting must be easily machinable to create intricate shapes, such as propeller shafts and couplings. This allows for efficient manufacturing and maintenance of the shafting components. 6. Non-Magnetic Properties: Special steel used in marine shafting should have low magnetic permeability to avoid interfering with sensitive navigation and communication equipment. Non-magnetic properties minimize the risk of compass errors and electromagnetic interference. 7. Certification and Compliance: The steel used in marine shafting should meet specific industry standards and certifications, such as those established by classification societies like the American Bureau of Shipping (ABS) or the International Association of Classification Societies (IACS). These certifications ensure the steel's quality, performance, and compliance with safety regulations. By meeting these specific requirements, the special steel used in marine shafting guarantees reliable performance, durability, and safety in marine applications.

- Q:How does special steel perform in corrosion fatigue conditions?

- Special steel performs well in corrosion fatigue conditions due to its high resistance to corrosion and fatigue. It is specifically designed to withstand harsh environments and prolonged exposure to corrosive elements. Special steel undergoes various treatments and alloying processes to enhance its corrosion resistance and mechanical properties. This allows it to maintain its structural integrity and performance even under corrosive and fatigue-inducing conditions.

- Q:How does special steel contribute to the manufacturing of molds and dies?

- Molds and dies are vital tools used across industries such as automotive, aerospace, and electronics to shape materials. They require durability, resistance to wear, and the ability to withstand high temperatures and pressures. Tool steel, also referred to as special steel, possesses distinct qualities that make it ideal for molds and dies. Firstly, its high hardness allows the tools to maintain their shape and surface integrity, even with extensive use and repetitive impacts. This hardness guarantees precision and accuracy in the final product. Furthermore, special steel exhibits excellent wear resistance, crucial as molds and dies come into contact with different materials during manufacturing. This wear resistance prolongs the lifespan of the tools, reducing the need for frequent replacements and minimizing production downtime. Moreover, special steel demonstrates good toughness, enabling it to absorb and endure high impact forces without fracturing or breaking. This is particularly important for molds and dies, which often undergo significant stress during manufacturing, especially when dealing with high-pressure or extreme temperature materials. Special steel also boasts high heat resistance, enabling molds and dies to withstand elevated temperatures used in certain manufacturing processes, such as injection molding or metal forging. This heat resistance prevents warping or loss of shape, ensuring consistent and accurate production. Additionally, special steel is easily machined and shaped, allowing manufacturers to create intricate designs for molds and dies. This versatility is essential as different industries require unique tool designs to meet specific manufacturing needs. In conclusion, special steel is crucial for manufacturing molds and dies due to its high hardness, wear resistance, toughness, heat resistance, and machinability. These unique properties enhance the durability, precision, and efficiency of molds and dies, ultimately improving the quality and productivity of various manufacturing processes.

- Q:How does special steel perform in cutting applications?

- Special steel performs exceptionally well in cutting applications. It has high hardness, excellent wear resistance, and superior toughness, allowing it to effectively cut through various materials with ease. Its exceptional performance ensures precise and clean cuts, making it a preferred choice in industries such as manufacturing, construction, and automotive. Additionally, special steel's ability to retain its cutting edge for prolonged periods minimizes the need for frequent sharpening or replacement, resulting in increased productivity and cost-effectiveness.

- Q:What are the different methods of preventing hydrogen-induced cracking in special steel?

- There are several methods that can be employed to prevent hydrogen-induced cracking in special steel: 1. Preheating: By preheating the steel before welding or any other high-temperature process, the risk of hydrogen-induced cracking can be reduced. Preheating helps in reducing the cooling rate of the steel, allowing hydrogen to diffuse out before it can cause cracking. 2. Heat treatment: Applying specific heat treatment processes like stress relieving or post-weld heat treatment can help alleviate hydrogen-induced cracking. These processes help in reducing residual stresses and promoting hydrogen diffusion, minimizing the risk of cracking. 3. Material selection: Choosing steel alloys with a higher resistance to hydrogen-induced cracking can be an effective preventive measure. Certain steel compositions, such as low carbon or low alloy steels, are less susceptible to cracking in the presence of hydrogen. 4. Hydrogen control during welding: Implementing techniques to minimize the introduction of hydrogen during welding is crucial. This can be achieved through the use of low-hydrogen welding consumables, such as low-hydrogen electrodes, and ensuring proper shielding gas coverage to prevent atmospheric moisture from contaminating the weld. 5. Stress management: Controlling the welding or operational stresses on the steel is important to prevent cracking. This can be achieved by using proper welding techniques, such as avoiding excessive heat input or rapid cooling rates, as well as minimizing the introduction of tensile stresses during welding. 6. Coating or surface protection: Applying protective coatings or surface treatments to the steel can act as a barrier against hydrogen absorption. These coatings can provide an additional layer of protection, reducing the risk of hydrogen-induced cracking. 7. Welding process optimization: Optimizing the welding parameters, such as current, voltage, and travel speed, can help reduce the risk of hydrogen-induced cracking. By adjusting these parameters, the heat input and cooling rate can be controlled, minimizing the potential for hydrogen absorption and subsequent cracking. It is important to note that a combination of these preventive measures is often necessary to effectively mitigate the risk of hydrogen-induced cracking in special steel. Additionally, proper inspection and quality control procedures should be implemented to ensure the integrity of the steel and detect any cracks or defects.

1. Manufacturer Overview |

|

|---|---|

| Location | Jiangsu, China |

| Year Established | 1990 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | Mid East; Eastern Europe; North America |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 20% - 30% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | 1 |

| Contract Manufacturing | OEM Service Offered; |

| Product Price Range | High; Average |

Send your message to us

Miniature Ball Bearings Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50MT m.t.

- Supply Capability:

- 500000TONS/YEAR m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords