All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

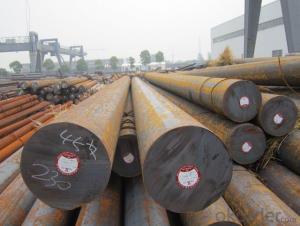

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How does special steel contribute to the production of components for next-generation electric aircraft?

Special steel plays a crucial role in the production of components for next-generation electric aircraft by providing the necessary strength, durability, and weight reduction properties. It enables the manufacturing of lightweight structures, such as airframes, wings, and landing gear, which are essential for achieving higher fuel efficiency and longer flight range. Additionally, special steel alloys offer excellent resistance to corrosion, extreme temperatures, and mechanical stresses, ensuring the aircraft's safety and performance. Ultimately, special steel contributes to the production of components that enhance the overall efficiency, reliability, and sustainability of next-generation electric aircraft.

What are the main alloying elements used in special steel?

The main alloying elements used in special steel vary depending on the specific type of special steel being produced. However, common alloying elements used in special steel include chromium, nickel, molybdenum, vanadium, tungsten, and cobalt. These elements are added to enhance the strength, hardness, corrosion resistance, and other desired properties of the steel.

What are the challenges and innovations in the recycling of high-alloy special steel?

The challenges in recycling high-alloy special steel primarily revolve around the complex composition and properties of the material. Special steels often contain various alloying elements, which can make the recycling process more difficult and costly. These alloys can affect the melting point, mechanical properties, and overall quality of the recycled steel. Additionally, contaminants such as dirt, oil, and coatings need to be removed before recycling, which adds to the complexity.

However, there have been significant innovations in the recycling of high-alloy special steel. Advanced technologies, such as electric arc furnaces and induction furnaces, have improved the efficiency and effectiveness of the recycling process. These furnaces can achieve high temperatures and precisely control the melting process, enabling the separation of different alloys and the removal of impurities.

Furthermore, advancements in sorting and separation techniques, such as magnetic and eddy current separation, have facilitated the separation of different types of steel and alloys during recycling. These innovations help to optimize the reuse of high-alloy special steel, minimizing waste and reducing the need for virgin materials.

Overall, while the challenges in recycling high-alloy special steel are significant, ongoing innovations and advancements in technology continue to improve the efficiency, effectiveness, and sustainability of the recycling process.

What is the role of molybdenum in corrosion-resistant steel alloys?

Molybdenum plays a crucial role in corrosion-resistant steel alloys as it enhances their resistance to corrosion and pitting. It forms a protective oxide layer on the surface of the steel, preventing the penetration of corrosive elements and providing long-term durability. Additionally, molybdenum improves the strength and toughness of the steel, making it suitable for various applications in harsh and corrosive environments.

Wholesale Special Steel from supplier in Brunei

Our team of experts is committed to understanding your specific requirements and providing personalized solutions. We offer a wide range of Special Steel products, including carbon steel, alloy steel, stainless steel, tool steel, and more. Whether you need round bars, flat bars, square bars, or any other form of Special Steel, we have you covered.

In addition to our product offerings, we also provide sales and quotation services. Our dedicated sales team is always ready to assist you in selecting the right Special Steel products for your project. We understand that every project is unique, and we strive to offer competitive prices and timely quotations to meet your budget and deadlines.

Furthermore, our technical support services ensure that you receive the necessary guidance and expertise throughout your project. Our team of engineers and technicians is equipped with in-depth knowledge of Special Steel and its applications. We can provide assistance in material selection, design optimization, and technical specifications to help you achieve the best results.

As a subsidiary of CNBM, we have access to a vast global network and resources. This allows us to ensure a seamless procurement experience for our customers in Brunei. We have established strong partnerships with reputable manufacturers and suppliers worldwide, enabling us to source high-quality Special Steel products at competitive prices.

Our presence and operations in Brunei have given us valuable insights into the local market. We understand the unique requirements and challenges faced by businesses in Brunei, and we are well-positioned to provide tailored solutions. Our knowledge of the local market dynamics allows us to offer informed advice and recommendations, ensuring that you make the right choices for your projects.

Overall, we are dedicated to providing comprehensive Special Steel solutions to our customers in Brunei. With our extensive product range, sales and quotation services, technical support, and market expertise, we are confident in our ability to meet your needs and contribute to the success of your projects. Contact us today to discuss your Special Steel requirements.

In addition to our product offerings, we also provide sales and quotation services. Our dedicated sales team is always ready to assist you in selecting the right Special Steel products for your project. We understand that every project is unique, and we strive to offer competitive prices and timely quotations to meet your budget and deadlines.

Furthermore, our technical support services ensure that you receive the necessary guidance and expertise throughout your project. Our team of engineers and technicians is equipped with in-depth knowledge of Special Steel and its applications. We can provide assistance in material selection, design optimization, and technical specifications to help you achieve the best results.

As a subsidiary of CNBM, we have access to a vast global network and resources. This allows us to ensure a seamless procurement experience for our customers in Brunei. We have established strong partnerships with reputable manufacturers and suppliers worldwide, enabling us to source high-quality Special Steel products at competitive prices.

Our presence and operations in Brunei have given us valuable insights into the local market. We understand the unique requirements and challenges faced by businesses in Brunei, and we are well-positioned to provide tailored solutions. Our knowledge of the local market dynamics allows us to offer informed advice and recommendations, ensuring that you make the right choices for your projects.

Overall, we are dedicated to providing comprehensive Special Steel solutions to our customers in Brunei. With our extensive product range, sales and quotation services, technical support, and market expertise, we are confident in our ability to meet your needs and contribute to the success of your projects. Contact us today to discuss your Special Steel requirements.