Hot Rolled Aluminum Coils for Oil Tanker

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Specification of Hot Rolled Aluminum Coils for Oil Tanker

Alloy: 1050, 1060, 1100, 3003, 3004, 3005, 3105, 5005, 5052, 5083, 5754

2) Temper: Various status

3) Thickness: 0.3-150mm

4) Width: 300-1950mm

5) Length: Under9500mm/ Coil

6) Weight: 2.5-5.0 tons per coil

7) Dimensions and weight can be produced according to clients' specifications.

8) Inner Diameter: 505mm, 605mm

9) Packing: Export standard, wooden pallet.

10) Delivery time: 20 days

11) Minimum order quantity: 5 tons per size.

12) The term of payment: T/T, irrevocable L/C at sight.

13) Surface: Bright

14)Origin: China

2. Application of Hot Rolled Aluminum Coils for Oil Tanker

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Hot Rolled Aluminum Coils for Oil Tanker

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

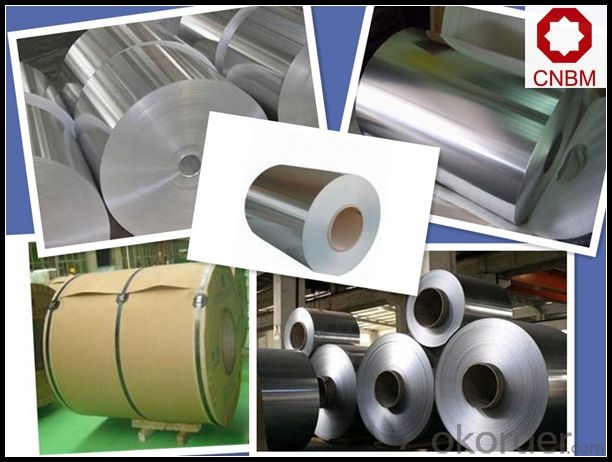

5. Image of Hot Rolled Aluminum Coils for Oil Tanker

6. Package and shipping of Hot Rolled Aluminum Coils for Oil Tanker

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q:I'm having trouble with another chem problemAluminum sulfide reacts w/water to form aluminum hydroxide and hydrogen sulfide. Write the balanced chemical equation for this reaction and find how many grams of aluminum hydroxide are obtained from 14.2 g of aluminum sulfide.I already found the balanced equation but I need help on finding how many grams of aluminum hydroxide are obtained from 14.2 g of aluminum sulfide. Can someone please explain how it's done?

- You use the given grams of Aluminum Sulfide, and use stoichiometry. First convert the Aluminum Sulfide from grams to moles [14.2g (1 mole of Aluminum Sulfide/total mass of Aluminum sulfide)]. Then, set up a mole ratio of Aluminum Sulfide to Aluminum Hydroxide (you do this by creating a ratio of the coefficients of both Aluminum Sulfide and Aluminum Hydroxide from your balanced equation; moles of Aluminum Hydroxide/miles of Aluminum Sulfide). And then finally convert back to grams (total mass of Aluminum Hydroxide/ 1 mole of Aluminum Hydroxide). In total, it should look like this: [14.2(1 mol Al Sulfide/mass of Al Sulfide)(mols of Al Hydroxide/mols of Al Sulfide)(mass of Al Hydroxide/1 mol of Al Hydroxide)]

- Q:Are aluminum coils suitable for food and beverage packaging?

- Yes, aluminum coils are suitable for food and beverage packaging. Aluminum is a versatile material that offers various advantages for packaging applications. It is lightweight, making it easy to transport and handle. Aluminum is also highly resistant to corrosion, which ensures that the packaging remains intact and protects the contents from external factors. Additionally, aluminum has excellent thermal conductivity, allowing for efficient heat transfer, which is beneficial for food and beverage products that require temperature control. It is also impermeable to light, moisture, and oxygen, providing an excellent barrier to maintain the quality and freshness of the packaged items. Furthermore, aluminum is recyclable and can be reused, making it an environmentally friendly choice for packaging. Overall, aluminum coils are a reliable and suitable option for food and beverage packaging due to their durability, protective properties, and sustainability.

- Q:How are aluminum coils coated or treated for specific applications?

- Aluminum coils are coated or treated for specific applications through various processes such as painting, anodizing, and thermal spraying. These treatments enhance the coil's durability, corrosion resistance, and aesthetic appeal. For example, painting involves applying a protective coating of paint to the aluminum surface, while anodizing involves creating a layer of oxide on the surface to improve resistance to wear and corrosion. Thermal spraying is another method where a coating material is sprayed onto the surface using heat, providing additional protection and specific functional properties.

- Q:What are the different coil coating options available for aluminum coils?

- There are several different coil coating options available for aluminum coils, each offering unique benefits and properties. 1. Polyester: Polyester coil coating is a popular choice due to its durability and cost-effectiveness. It provides good resistance to weathering, UV rays, and chemical exposure. Polyester coatings are available in a wide range of colors and finishes, making them suitable for various aesthetic applications. 2. Polyvinylidene Fluoride (PVDF): PVDF coatings offer superior durability and resistance to UV rays, weathering, and chemicals. They have excellent color retention and can withstand harsh environmental conditions. PVDF coatings are commonly used in architectural applications where long-term durability and aesthetics are critical. 3. Polyurethane: Polyurethane coil coatings provide excellent adhesion, flexibility, and impact resistance. They are known for their high gloss and vibrant colors. Polyurethane coatings are often used in applications requiring superior resistance to abrasion, such as appliances and automotive components. 4. Epoxy: Epoxy coil coatings offer excellent corrosion resistance and adhesion properties. They are commonly used in industrial applications where protection against chemicals and harsh environments is required. Epoxy coatings can be applied as a primer or a topcoat, depending on the specific requirements. 5. Acrylic: Acrylic coil coatings provide good weather resistance, color retention, and gloss. They are often used in outdoor applications where exposure to UV rays and environmental conditions is a concern. Acrylic coatings can be formulated to achieve different levels of durability and flexibility. 6. Silicone Modified Polyester (SMP): SMP coil coatings combine the benefits of polyester and silicone, offering enhanced weather resistance and durability. They provide excellent color retention, gloss retention, and resistance to chalking. SMP coatings are commonly used in architectural and industrial applications. It is important to consider the specific requirements of the application, including durability, aesthetics, and environmental conditions, when selecting the appropriate coil coating option for aluminum coils. Consulting with a coil coating expert can help determine the best option based on the desired performance and appearance.

- Q:Are aluminum coils recyclable?

- Yes, aluminum coils are recyclable. Aluminum is a highly recyclable material, and it can be melted down and reused to make new products, including coils. Recycling aluminum helps conserve natural resources and reduce energy consumption.

- Q:Can aluminum coils be used in the production of fire-resistant structures?

- Indeed, the utilization of aluminum coils is possible for the fabrication of fire-resistant structures. Being inherently fire-resistant and possessing a remarkably high melting point, aluminum emerges as an excellent substance for structures that necessitate endurance against elevated temperatures. In the realm of construction, aluminum coils are frequently employed to fulfill fire-resistant requirements, including roofs, walls, and insulation. Moreover, the lightweight and durability of aluminum further facilitate the installation and maintenance of fire-resistant structures.

- Q:What are the bending and forming capabilities of aluminum coils?

- Aluminum coils have excellent bending and forming capabilities due to the inherent properties of aluminum as a malleable and ductile material. Aluminum is known for its high strength-to-weight ratio, which allows it to be easily shaped and formed without compromising its structural integrity. When it comes to bending, aluminum coils can be bent into various shapes and angles without fracturing or cracking. The flexibility of aluminum allows it to be formed into tight curves or gentle bends, making it suitable for a wide range of applications. This flexibility is particularly advantageous in industries such as construction, automotive, and aerospace, where curved or complex shapes are often required. In terms of forming, aluminum coils can be easily manipulated into different forms, including flat sheets, tubes, or intricate profiles. This versatility makes aluminum coils highly sought after in industries where customization and design flexibility are important. Furthermore, aluminum coils can undergo various forming processes such as roll forming, stamping, and deep drawing, allowing them to be transformed into different products with precise dimensions and tolerances. These forming capabilities make aluminum coils a preferred choice for manufacturing components, such as automotive body panels, roofing materials, heat exchangers, and structural elements. Overall, the bending and forming capabilities of aluminum coils are exceptional, making them an ideal choice for applications that require flexibility, durability, and design versatility.

- Q:Are aluminum coils suitable for beverage can manufacturing?

- Yes, aluminum coils are suitable for beverage can manufacturing. Aluminum is a preferred material for beverage cans due to its various advantageous properties. Firstly, aluminum is lightweight, which makes it easy to transport and handle. This is particularly important for the beverage industry, where large quantities of cans are produced and distributed. Additionally, aluminum is highly malleable, allowing it to be formed into the desired shape without losing its structural integrity. This makes it ideal for can manufacturing, as it can be easily shaped into a can's cylindrical form and withstand the pressure from carbonated beverages. Moreover, aluminum is a non-toxic material, ensuring that it does not contaminate the beverages stored in the cans. It also provides a barrier against light, oxygen, and moisture, which helps to preserve the taste and quality of the beverages. Furthermore, aluminum is recyclable, making it an environmentally friendly choice for can manufacturing. The recycling process for aluminum requires significantly less energy compared to producing new aluminum, making it a sustainable material option. Overall, the suitability of aluminum coils for beverage can manufacturing is evident due to its lightweight nature, malleability, non-toxicity, preservation properties, and recyclability.

- Q:What are the standard tolerance levels for aluminum coils?

- Depending on the industry and application, the tolerance levels for aluminum coils can differ from the standard. Generally, these tolerance levels are established by industry standards and specifications like ASTM or ISO. For thickness, the tolerance levels for aluminum coils can range from +/- 0.002 inches to +/- 0.020 inches, depending on the aluminum's specific grade and thickness. Similarly, the tolerance levels for width can vary from +/- 0.010 inches to +/- 0.250 inches. Regarding flatness, the standard tolerance levels for aluminum coils specify the maximum deviation from a flat plane. This can range from 0.001 inches to 0.020 inches, depending on the application's specific requirements. Other factors that can affect tolerance levels include the aluminum coils' surface finish, edge condition, and mechanical properties. To determine the appropriate tolerance levels for aluminum coils, it is important to consult relevant industry standards, specifications, and the specific requirements of the application.

- Q:What are the different coil coating technologies used for aluminum coils?

- Aluminum coils can be coated using various technologies, each with its own advantages and suitability for specific applications. The first method involves applying liquid coatings onto the aluminum coils. These coatings can be solvent-based or water-based and are typically applied using roll coating or spray coating techniques. Liquid coatings provide a wide range of color options, excellent chemical resistance, and good adhesion to the substrate. However, they may take longer to dry and result in uneven coating thicknesses. Another method is using powder coatings, which are electrostatically applied as a dry powder onto the aluminum coils. The coated coils are then heated to melt and cure the powder, creating a tough and durable finish. Powder coatings offer excellent corrosion resistance, UV resistance, and impact resistance. They also have a high deposition efficiency, resulting in minimal waste. However, compared to liquid coatings, they may have limited color options. PVDF coatings are a type of liquid coating known for their exceptional weatherability and durability. They are resistant to fading, chalking, and chemical exposure, making them suitable for architectural applications requiring long-term performance and color retention. PVDF coatings can be applied using roll coating or spray coating methods. Polyester coatings are widely used in various industries due to their cost-effectiveness and versatility. They offer good color retention, flexibility, and resistance to abrasion. Available in a wide range of colors and textures, polyester coatings are suitable for decorative applications. They can be applied using both liquid and powder coating methods. Polyurethane coatings provide excellent adhesion, flexibility, and impact resistance. They are commonly used in demanding applications that require durability and resistance to harsh environments. Polyurethane coatings offer good color retention and can be applied using liquid coating techniques. In conclusion, there are several different coil coating technologies available for aluminum coils, including liquid coatings, powder coatings, PVDF coatings, polyester coatings, and polyurethane coatings. The choice of coating technology depends on factors such as desired performance characteristics, application requirements, and cost considerations.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Rolled Aluminum Coils for Oil Tanker

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords