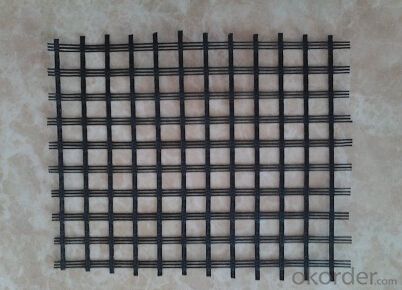

High Tensile Strenth Polyester Geogrid with CE Certifcate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 roll

- Supply Capability:

- 19999999 roll/month

- Option:

- 2x100m

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Description of High Tensile Strength Polyester Geogrid

we have CE , ISO9001 certificate..Polyester Geogrid for Road Railway Highway Tunnel is Made from PET fiber by weaving technology after gummed processing

Specification of High Tensile Strenth Polyester Geogrid with CE Certifcate:

1.Strength: 20x20kn/m--600x600kn/m, such as :60/30, 60/60, 80/30, 120/30, 150/30, 200/30 etc.

2.Polyester Geogrid coated with PVC, Bitumen, SBR

3.Elongation:10% and 13%

4.Width: 1--6m

5.Packing:50m or100m/roll,

PE film outside, plstic tube inside.also can be made according clinet's need.

Application of High Tensile Strenth Polyester Geogrid with CE Certifcate:

(1)Roadbed reinforcement of road and railway, crack prevention, increase of roadbed strength;

(2)Reinforcement and stabilization of riverside, embankment and side slope;

(3)Dyke reinforcement on soft ground for stress evenness, sedimentation adjustment, increase of stability and loading capacity of fundus;

(4)Reinforcement of the surface of road and bridge

Property of Polyester Geogrid for Road Railway Highway Tunnel

I. High tensile strength

2. Low elongation

3. Anti-erosion, anti-aging

4. Good affinity with base material

5. Lig ht weig ht, water d rainage

FAQ

What is your advantages ?

I. Not easy to produce static after friction. In the coal mine, surface static resistance average is

Below lx109Q

2. Good flame retardant performance

3. Strong anti-corrosion and rust resistance

4. High bearing capacity, low elongation

- Q:What is a one-way plastic geogrid

- As the polymer in the manufacture of plastic polymer in the process of heating with the extension of the process of re orientation, strengthen the link between the molecular chain force, to achieve the purpose of improving its strength. Its elongation rate is only 10% ~ ~ of the original plate of 15%. If the carbon black and other anti-aging materials are added in the geogrid, the utility model has the advantages of good acid resistance, alkali resistance, corrosion resistance, aging resistance and the like

- Q:What are the advantages of using geogrids in ground improvement for liquefaction mitigation?

- There are several advantages of using geogrids in ground improvement for liquefaction mitigation. Firstly, geogrids provide increased stability to the soil by reinforcing it. They are placed in the ground to create a strong and stable layer, preventing soil liquefaction during earthquakes or other seismic events. This reinforcement helps to improve the overall strength and load-bearing capacity of the soil, making it less susceptible to liquefaction. Secondly, geogrids can improve the drainage properties of the soil. By creating a network of interconnected voids, they allow water to drain more efficiently, reducing the excess pore water pressure that contributes to liquefaction. This improved drainage helps to maintain the integrity and stability of the soil, even under seismic loading. Additionally, geogrids are cost-effective compared to other ground improvement techniques. They are relatively easy to install and require minimal excavation, reducing construction time and costs. Moreover, their long lifespan and durability make them a sustainable solution for liquefaction mitigation, minimizing the need for frequent maintenance or replacement. Overall, the use of geogrids in ground improvement for liquefaction mitigation offers enhanced stability, improved drainage, and cost-effectiveness, making them a valuable tool in mitigating the risks associated with soil liquefaction.

- Q:The difference between composite geomembrane and bentonite waterproof blanket

- Different waterproof performance. Composite geomembrane: composite geomembrane composite impermeable membrane is divided into one cloth and two membrane. Tensile, tearing resistance, bursting and other physical and mechanical properties of high index, the product has high strength, good elongation, deformation modulus, acid and alkali resistance, corrosion resistance, aging resistance, good performance of seepage control, etc..

- Q:What is the recommended geogrid aperture shape for specific applications?

- The recommended geogrid aperture shape for specific applications varies depending on the specific requirements of the project. However, commonly used shapes include square, rectangular, and hexagonal apertures. These shapes provide different levels of stability, soil confinement, and load distribution, allowing engineers to select the most suitable option based on factors such as soil type, slope angle, and anticipated loads.

- Q:Polypropylene geogrid

- You said the polypropylene geogrid, generally only two-way plastic geogrid and one-way plastic geogrid is polypropylene material

- Q:Can geogrids be used in reinforcement of underground structures?

- Yes, geogrids can be used in the reinforcement of underground structures. Geogrids are highly effective in providing tensile strength and stability to soil, which makes them ideal for reinforcing the ground surrounding underground structures such as tunnels, retaining walls, and underground tanks. They help to distribute loads and prevent soil movement, enhancing the structural integrity and longevity of these underground constructions.

- Q:Are geogrids suitable for use in slope stabilization for mining haul roads?

- Yes, geogrids are suitable for use in slope stabilization for mining haul roads. Geogrids are effective in enhancing the strength and stability of the soil by improving its load-bearing capacity and reducing soil erosion. They provide reinforcement and confinement to the soil, preventing soil movement and instability. Additionally, geogrids are durable, cost-effective, and easy to install, making them a practical choice for slope stabilization in mining haul roads.

- Q:Do geogrids require maintenance?

- Yes, geogrids do require maintenance. Routine inspection is necessary to ensure their proper functioning and longevity. This may involve checking for any signs of damage, such as tears or punctures, and addressing any issues promptly. Additionally, regular cleaning and removal of debris is important to prevent clogging and maintain the effectiveness of geogrids. Overall, proper maintenance helps to extend the lifespan and performance of geogrids in various applications.

- Q:The price of the type of geogrid manufacturers is the best phone

- No long-term creep as reinforcing material, have in long-term load under the condition of deformation resistance that the creep resistance is extremely important, glass fiber does not creep, which ensure product can maintain long-term performance.

- Q:What is high strength geogrid

- High strength geogrid grille is actually refers to the large geogrid,

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Tensile Strenth Polyester Geogrid with CE Certifcate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 roll

- Supply Capability:

- 19999999 roll/month

- Option:

- 2x100m

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords