High Quality Oil Free Scroll Vacuum Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100000000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Oil Free Scroll Vacuum Pumps

1.Structure of Oil Free Scroll Vacuum Pump

single stage rotary vane vacuum pumps combining with many years of experience in vacuum engineering and the latest international vacuum technology developed to meet requirements of both the industry and the environment.They are being used in all areas of vacuum engineering. They are equally suited for both industrial production and research applications. They may be used to generate a rough and medium vacuum or as backing pumps in pump combinations with Roots pumps or high vacuum pumps. The comprehensive range (pumping speeds ranging from 10 to 630 m 3 / h) allows every customer to select the right pump for his particular needs.

2.Main features of Oil Free Scroll Vacuum Pump

• Long life design

• The comprehensive range from 10 to 630 m 3 / h

• Vacuum pump entirely replace the pumps like U3/U4,R5,VC,EU and etc.

• High pumping speed also at low pressures

• Optimum price-to-performance ratio

• Low noise level

• Low vibrations

• Integrated exhaust filter, up to 99.9% efficient

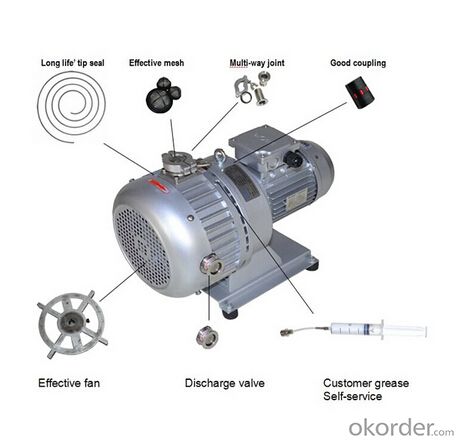

3.Oil Free Scroll Pump Images

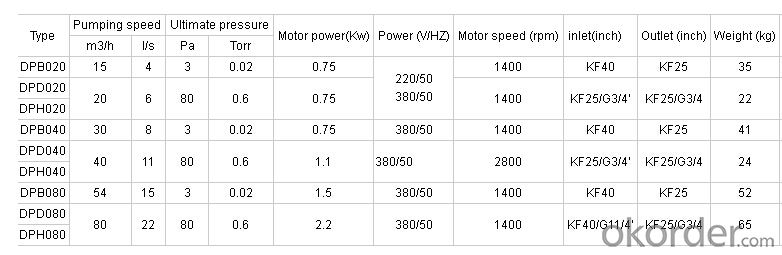

4.Oil Free Scroll Vacuum Pump Specification

5.FAQ

①Application

Food industry , Vacuum packaging, Material drying, Car industry , Furnaces and plants , chemical, Laser technology , Medicinal technology , Metallurgy , Power engineering , Space simulation , Vacuum coating , vacuum loading, electronics, semiconductor, scientific research

- Q:Rules for operation of centrifugal pumps

- Working principle and process flowWorking principle: when the drive motor with high-speed rotating impeller, full of fluid in the pump body under the action of centrifugal force, was thrown from the impeller center to the outer edge of the impeller, in this process, the fluid energy, improve the pressure can, at the same time also increases the energy flow rate increase. The liquid from entering the pump impeller shell, the liquid flow gradually widened, the liquid velocity decreased gradually, which will be part of the kinetic energy into pressure energy, which further improves the static pressure of liquid, and liquid with high pressure in pressure pipeline. When the liquid from the leaves out when the impeller center creates pressure and low pressure than the out plane is big, under pressure drive, liquid is continuously from the center of the impeller suction, with the pressure of continuous discharge.

- Q:What are the constant pressure pumps?

- Chlorine booster pumpThe pressure range of chlorine booster pump is large, and different pump can be used to obtain different pressure area. The input air pressure is adjusted and the output pressure is adjusted accordingly. High pressure can be reached, gas 90Mpa. Wide range of flow, for all types of pumps only 0.1Kg pressure can work smoothly, at this time to obtain the minimum flow, adjust the intake volume can be obtained after a different flow. Easy to control, from simple manual control to fully automatic control, can meet the requirements. Automatic restart, regardless of what causes the pressure drop in the pressure loop, will automatically restart to supplement leakage pressure and maintain constant loop pressure. Safe operation, gas driven, no arc and spark can be used in dangerous situations.

- Q:What is the relationship between the minimum suction vacuum of a pump and the required cavitation?

- Suction is allowed to pump the vacuum from the distance from the inlet, which is part of the field installation.The manufacturer of cavitation allowance is closely related to the design and process of pump. Estimation formula: cavitation allowance =10.33 meters - allow suction of -0.5 meters (safety).

- Q:What's the meaning of the pump head in the water pump, please advise, thank you

- In general, the pump removes the motor, and all the fittings are part of the pump head.A pump is a machine that transports liquids or pumps liquids.

- Q:Pneumatic diaphragm pump compressed air pressure is 4 kg, the discharge pressure is how big?

- Have to know the ratio, pneumatic pump, if high pressure, you can have 2:1,3:1

- Q:The difference between submersible pumps and centrifugal pumpsWhat's the difference between the two? What is applicable and what?

- High speed rotating impeller blade drives the liquid to rotate, and the liquid is thrown out so as to achieve the purpose of conveying. There are many medium for transportation, such as oil, water, chemicals and so on. The pump shaft and the motor shaft are of the same shaft, the pump and the motor are made into an integral body and immersed in water. The medium of transportation is water.

- Q:Types and differences of pumps

- (I) volumetric typeClassification reciprocating rotary typeThe basic principle of reciprocating action by the piston in the cylinder in the cylinder volume changes again, with the suction and discharge of fluid in the shell or the rotor rotating member rotates, the volume of work between rotor and casing changes to the suction and discharge fluid, such as piston pump gear pump, screw pump(two) blade type;The main structure of vane pumps and fans is rotary, bladed impellers and stationary housings that rotate fluid through the impeller to do work, thereby enabling fluids to obtain energy

- Q:Roots pump and dry pumpRecently involved in the work of the vacuum pump, don't understand this, is a ads602 vacuum pump, composed of roots pump and dry pump, is pre pumped to the 500mtorr equipment, the main pumping vacuum continues to 10mtorr, where the roots pump and dry pumps must be used? What role they play respectively. The so-called dry pump? Is refers to one kind of the pump, the pump is many dry pump? Also do not understand how the work of automatic switching system for pre pumping, the main pump, pump work alone did not connect system ah (of course there are even a butterfly) teach?

- Different working conditions, our company does dry claw pump alone can also achieve the vacuum of 133 PA.

- Q:What's the difference between a concrete pump and a concrete pump truck?

- Concrete pump and concrete pump truck are concrete conveying machinery, use the same, but the former need to transport and car towing need additional support pipeline, the locomotive body and arm extends freely, without pipeline, hundreds of thousands of millions of the former, the latter

- Q:Pump unloading in hydraulic transmission,

- Unloading is pumping oil directly back to the tank, the pressure is very low, energy saving

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Quality Oil Free Scroll Vacuum Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100000000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords