High Quality Forged Steel Full Bore High Pressure Ball Valve

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20 Sets pc

- Supply Capability:

- To Order pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Quality Forged Steel Full Bore High Pressure Ball Valve

Design Features Of High Quality Forged Steel Full Bore High Pressure Ball Valve:

Blow-out proof stem

Key lock

Anti-fire safe design

Anti-static device

Free leakage of body Sealed construction

Double block&bleed (DBB)

Emergency sealing

Automatic body cavity relief

Various driving types

Fire safe design to API 607/ API 6FA

Anti-static to BS 5351

Cavity pressure self relief

Optional locking device

Specifications of High Quality Forged Steel Full Bore High Pressure Ball Valve:

Size: 1/4"-2"

Pressure: Class150LB-900LB

Material: WCB, LCB, CF8, CF8M, CF3, CF3M, A105, LF2, F304, F316, F304L, F316L,ASTM A351

Design & Manufacture Std.: API608, ASME B16.34

Connection Ends: Threaded (Female/Female), NPT, BSP, BSPT, DIN259/2999, Butt welded, Socket welded (BW, SW)

Test Standard: API598

Structure Type: One-piece, Two-piece, Three-piece, Reduced Bore

Operated way: Lever

Suitable medium: Water, oil, steam, nitric acid, acetate acid and so on

Suitable temperature: -40 deg+150deg be able to endure high pressure

Seat: PTFE. Material and good on-off feature.

Working pressure: 1000psi

Thread standard: International BSPT, NPT, DIN, surface is flat, allow overrun

|

Nominal pressure |

PN(mpa) |

2.5 |

4 |

6.4 |

|

|

Shell Test Pressure |

PS(mpa) |

3.75 |

6 |

9.6 |

|

|

Sealing test pressure |

2.75 |

4.4 |

7.04 |

| |

|

TightnessTest Pressure |

0.6 |

0.6 |

0.6 |

| |

|

For media |

SS201 |

SS304 |

SS316 |

| |

|

Water, oil and gas medium |

Nitric acid corrosive media |

Acetic acid corrosive medium |

| ||

|

For temperature |

-40°C——+150°C |

||||

|

Product Standards |

GB/T12237-2007 |

| |||

|

Test |

GB/T13927-1992 JB/T9092-1999 |

||||

Applicable Standard Of High Quality Forged Steel Full Bore High Pressure Ball Valve:

Design Standard: API 6D, ASME B16.34, API 608, BS 5351, MSS SP-72

Face to Face: API 6D, ASME B16.10, EN 558

End Connection: ASME B16.5, ASME B16.25

Inspection and Test: API 6D, API 598

Design Description Of High Quality Forged Steel Full Bore High Pressure Ball Valve:

Double block and bleed design(DBB)

Double stem sealing. The ball can maintain pressure sealing of pipeline when it is closed or fully opened.

Shorter upper sleeve reduces bearing load and operation torue

Limit device ensures the accurate opening and closing position of the valve

The vall and stem are separated so as to reduce stem load. The stem adopts anti-blow-out design.

The sealing surface is inserted into te metal seat by polymer or plastic

The metalbacked self-lubricating PTFE bearing and PTFE thrust washers

Reduce the opening torque and prolong the service life of the valve. Stem leakage can be prevented through the emergency grease fitting.

Nickel and phosphor treatment to the parts can enhance the anticorrosive performance.

The fireproof design of metal wound gasket compassed of stainless steel and graphite can prevent external leakage.

Usage/Applications Of High Quality Forged Steel Full Bore High Pressure Ball Valve:

It can be widely used in Metallurgy, Mine, Petrochemical, Chemical, Oil & Gas transmission pipeline, Power plant, Heating power and Pharmacy, etc.

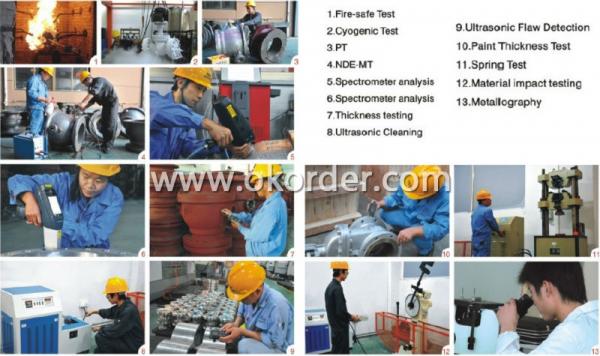

Main Test Of High Quality Forged Steel Full Bore High Pressure Ball Valve:

Packaging & Delivery Of High Quality Forged Steel Full Bore High Pressure Ball Valve:

Packaging: Inner packing: Plastic bags, Outer packing: Cartons and wooden case.

- Q:Pneumatic ball valve q641f-16p what do you mean?

- Q is a ball of the code, 6 representative driving mode is pneumatic, 4 flanged ball valve structure is straight through channel 1 on behalf of the floating ball, f sealing surface is the fluorine plastics, 16 represents the pressure of 16 kg, P represents the body material is stainless steel, Shandong Huadian valve.

- Q:DN80/DN100/DN125 how big is the outer diameter of the ball valve flange?

- The outer diameter of the ball valve depends on what kind of flange you useAt present, the domestic commonly used flanges are marked with JB/T (formerly mechanical industry standard), GB/T (GB), HG (Ministry of chemical industry).

- Q:Is the integral type split ball valve structurally identical?

- Split type ball valve, the valve body by the main body and the cover body is composed of two parts, thread connection between the main body and the cover body is arranged at the connection of the sealing ring, an annular sealing ring and ball valve, valve rod, sealing gasket, valve stem nut, a handle, a fastening nut is arranged on the main body, there is another ring the sealing ring is arranged on the cover body, interface screw holes at both ends of the valve body are respectively processed in the main body and cover body. This structure of the ball valve, the ball cavity depth is relatively shallow, the ball cavity processing is more convenient.

- Q:Stainless steel ball valve, Q11F-10P, 16P, 11F, what does that mean?

- Q11F-10P 16P is the meaning of stainless steel internal thread ball valve. One is 10 kilograms, one is 16 kilogramsQ valve Code: ball valveManual no code representation1 connection: internal thread1 structure form: floating through typeF sealing material: fluoroplastic10 valve pressure: 10 kg 1.0MPa 16=1.6mpaP body material: stainless steel

- Q:What is the difference between gas ball valve RQ11F-25P and ordinary stainless steel spike valve Q11F-25P?

- The models are all the same. What's the difference? Q ball valve, 1 internal thread, 1 floating through type, F PTFE sealing, 25=2.5mpa, P stainless steel.

- Q:1 piece, 2 piece, 3 piece ball valve, which places are used in large quantities?

- Structural features of two piece ball valve:1, opening and closing without friction. This function completely solve the traditional valve because of the friction between the sealing surface and affect the sealing problem.2, top structure. The valve installed on the pipeline can be directly checked and maintained, which can effectively reduce the device parking and reduce the cost.3, single seat design. The utility model eliminates the problem that the medium of the valve in the valve is influenced by the abnormal voltage increase.4 、 low torque design. Special structural design of the valve stem, with only a small hand, the valve can easily open and close.5 wedge sealing structure. Valve is provided by the mechanical force of the valve stem, the ball wedge to the seat and seal, so that the valve sealing is not affected by changes in pipe pressure, in a variety of conditions, sealing performance has a reliable guarantee.6. Self-cleaning structure of sealing surface. When the ball roll off the seat when the fluid in the pipeline along the sealing surface of the sphere into 360 degrees evenly through, not only eliminates the high speed fluid on the seat of local scour, also washed away the sediment on the sealing face, achieve the purpose of cleaning.

- Q:The difference between a cricket valve and a constant pressure valve

- Ball valve for ball ball column shape and called, is mainly to be closed, and often switch when the fluid flow control to throttle function and design, is the main characteristic of effective throttling, to minimize and reduce the phenomenon of drawing valve and valve seat dip (wash) inhibition, but because of the seat is parallel to the line, change the flow of fluid through the valve seat will be in class.

- Q:Ball valve, PTFE pad inappropriate choice, is not easy to bad ah?

- 120 - 150. TemperatureChasing the answerYes, but not in a high temperature for a long time, like more than 180 degrees centigrade. Because the gasket can not be used after deformation, it will cause valve leakage.

- Q:Flange ball valve Q41P3-150C2, DN50, RF, WCB/316 hardening, each letter number represents what?

- P3, C2? Uncultured, I know P and C, P is the sealing surface material boroning steel is above C, WCB or A105But you Tidianyijian pressure 15MPa, RF surface is not well, the best is to use RJ flange

- Q:Replacement method of PPR hot melt ball valve

- 1, need to replace the valve, if the valve is flange or wire connection type, directly open flange or loosen the screw, the ball valve can replace a broken;

1. Manufacturer Overview |

|

|---|---|

| Location | Zhejiang, China |

| Year Established | 2004 |

| Annual Output Value | Below US$1 Million |

| Main Markets | North America; South America; MidEast; Africa; Oceania; East Asia; Europe; Japan; Southeast Asia |

| Company Certifications | ISO 9001:2008; CE; API-6D |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Wenzhou |

| Export Percentage | 1% - 10% |

| No.of Employees in Trade Department | 101-200 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | 8000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

High Quality Forged Steel Full Bore High Pressure Ball Valve

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20 Sets pc

- Supply Capability:

- To Order pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords