High Quality and Good Price Suspension Ceiling Grids From China

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Structure of (Flat Suspension Grids) Description

t grids ceiling system

1 Materiel: Galvanized steel & prepainted

2 Size: H38&H32 H15

3 System: flat & groove

fut ceiling t grid

Materiel: Hot dipped galvanized steel & prepainted

Surface:Baking Finish

System: flat ceil & groove ceiling

2,Main Features of the (Flat Suspension Grids)

Shape:Plane,groove

Groove T bar ceiling grid (FUT) & FUT Ceiling Grid system is made of high quality prepainted galvanized steel,which guarantee the characters of moisture proof,corrosion resistanct and color lasting.The automatic cold roll forming and punching machineries guarantee the high precision.

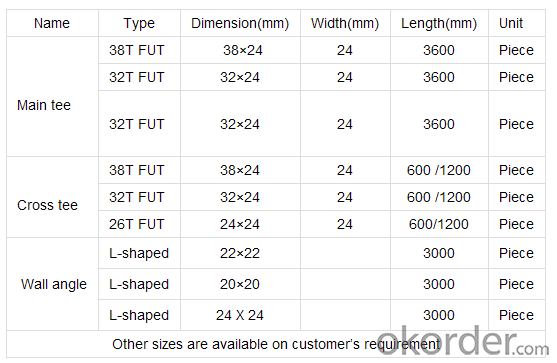

Standard size:

1. Main tee:38x24x3000/3600mm(10'),(12'); 32x24x3000/3600mm(10'),(12')

2. Cross tee:32x24x1200mm (4');26x24x1200mm (4')

3. Cross tee:32x24x600mm (2'); 26x24x600mm (2')

4. Wall angle:24x24x3000mm (10'); 22x22x3000mm (10'); 20x20x3000mm (10')

5. Thickness:0.25mm,0.27mm,0.3mm,0.35mm,0.4mm

6. The length, thickness and color can be provided in accordance with customers'

requirements.

3,(Flat Suspension Grids) Images

4,(Flat Suspension Grids) Specification

5,FAQ of (Flat Suspension Grids)

1. Convenience in installation, it shortens working time and labor fees.

2. Neither air nor environment pollution while installing. With good effect for space dividing and beautifying.

3. Using fire proof material to assure living safety.

4. Can be installed according to practical demands.

5. The physical coefficient of all kinds Suspension

Standard size:

1. Main tee:38x24x3000/3600mm(10'),(12'); 32x24x3000/3600mm(10'),(12')

2. Cross tee:32x24x1200mm (4');26x24x1200mm (4')

3. Cross tee:32x24x600mm (2'); 26x24x600mm (2')

4. Wall angle:24x24x3000mm (10'); 22x22x3000mm (10'); 20x20x3000mm (10')

5. Thickness:0.25mm,0.27mm,0.3mm,0.35mm,0.4mm

6. The length, thickness and color can be provided in accordance with customers'

requirements.

- Q:What are the meanings of the letters in the CB, DB CS, DF DM of the light steel keel? Seeking different people to explain ah

- (50 * 19 * 0.5, 50 * 20 * 0.6, 60 * 27 * 0.6), DB: Ceiling keel is not on the people (including the ceiling bearing keel: 38 * 12 * 1.0 and ceiling cover keel)

- Q:A few months back, a leak in the ceiling allowed water to pool atop a ceiling tile and cause it to collapse in the center. The debri was swept or mopped up, I don't know (but the floor has since been mopped) -- however, the tile, still broken, is just hanging there from the ceiling, and has been for all this time.

- No, it's not. -they didn't start using grid ceilings until the late, late 80's and that isn't even remotely asbestos laced. I thought maybe by your post you were dealing with the perforated stick on tiles that affix to the ceiling.(they are 10 X 10) The tile you have can't be older than '89. Go to Home Depot and pick up a new one, 5 bucks.

- Q:Light steel keel wall need square steel do

- Light steel keel wall materials are 50, 75, 100, 150 and several other. The wall can be filled with insulation materials - sound insulation materials (such as rock wool board, rock wool felt, bubble board), etc., can play a very good sound insulation effect.

- Q:GB keel, ordinary dragon brand gypsum board 9.5mm

- In contrast, the cost of light steel keel is higher. An ordinary gypsum board price is also about 20 dollars - up to no more than 25 dollars, per square meter (single layer) 6 to 8 dollars look. And a vice keel will be more than ten dollars, plus expansion screws, hanging tendons, the main keel, the cost will be gypsum board 2 to 3 times (or more).

- Q:They're usually square-shaped with grid wire.They usually have lights behind them. I'm looking for only one. Any ideas where I could get one?

- All your big box stores such as Home depot or Lowes will carry them. Any electrical supply house will also carry them. They are most of the time a white or clear plastic. Any questions you can e mail me through my avatar. GL

- Q:Light steel keel dry wall nail and ordinary dry wall nail What is the difference?

- Need to drink good water is our family's body rather than our new house, to parents, their own one, the whole family can use. Pro, you do not install and do not install, and TV will be the same as the rapid popular air conditioning, late installed as early as early morning, early morning health.

- Q:Is it nice to use a light steel keel or a wooden keel?

- Of course, is the light steel keel, you can choose DU50 system ceiling keel, carrying keel thickness of not less than 1.0mm (GB 1.2), cladding keel thickness of not less than 0.45mm (GB 0.5)

- Q:Do not know who can tell me ah

- Install the main keel 1) The main keel should hang on the boom. The main keel spacing 900 ~ 1000mm. The main keel is divided into light steel keel and T-shaped dragon bone. Light steel keel can be used UC50 keel and UC38 keel. The main keel should be parallel to the room to the long installation, at the same time should be From arch, arch height for the room span of 1/200 ~ 1/300. The cantilever section of the main keel should not be greater than 300mm, otherwise Should increase the boom. The main keel should be docked, and the butt joints of the adjacent keels should be staggered from each other. The main keel hangs well After the basic leveling. 2) Span greater than 15m above the ceiling, should be in the main keel, every 15m plus a large keel, and vertical main keel Welded firmly. 3) If there is a large modeling ceiling, the shape part of the application of angle or flat steel welded into a frame, and should be connected with the floor firmly. (6) install the keel Times keel clear keel and dark keel two. Dark keel ceiling: that is, when the installation panel cover the keel will be closed in the shed, in the The roof surface can not see the keel. Ming keel ceiling: the installation of the panel when the keel exposed under the cover panel, in the ceiling The surface can see the keel. The keel should be close to the main keel. Times keel spacing 300 ~ 600mm. Times the keel points T-shaped paint keel, T-shaped aluminum alloy keel, and a variety of strip buckle manufacturers with a dedicated keel. T-shaped galvanized When the sub-keel is fixed to the main keel, the ends of the keel shall be seated on the horizontal flange of the L-shaped keel On the bar buckle plate has a dedicated angle to do the keel. (7) cover panel installation Hanging roof cover panels commonly used plate with sound-absorbing mineral wool board, silicon calcium board, plastic plate, grille and a variety of Kouban, etc.

- Q:I have a suspended ceiling that is 2' x 4'- the guy at Lowe's told me I can use the USG Lace 12 x 12 tiles to interlock to have 8 of them fit in a grid...is this actually possible? Everything I have seen online says that those are to staple or glue up- not to be placed in a 2' x 4' grid.

- I wouldn t think you could either. I would think that middle seam would sag after awhile,. Go with your gut and don t ... GL

- Q:4' x 2' acoustical ceiling tiles, separated by 1 1/2 metal strips. Every few feet, a 2' x 4' florescent lighting fixture.I'm an artist and have paintings on every spare inch of wall space..including the back of the door. Out of space to hang canvas and paint.Am considering hanging framed canvas from the metal strips on the ceiling.Does anyone know how much weight the drop, acoustical ceiling dividers can take..without crashing to the floor..taking the florescent lighting fixture(s) with it?..give or take..?

- a few pounds max. this stuff is only made to support the mass of the tiles. it will fold faster than superman on laundry day if you load it up.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Quality and Good Price Suspension Ceiling Grids From China

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords