High Purity Calcined Bauxite Powder with Good Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Quick Details

| Place of Origin: | Henan, China (Mainland) | Shape: | Powder | Material: | Castable |

| SiO2 Content (%): | 0.5-15 | Al2O3 Content (%): | 55-95 | MgO Content (%): | 0.3 |

| CaO Content (%): | 0.3 | Refractoriness (Degree): | 1770°< Refractoriness< 2000° | CrO Content (%): | 0.1~0.3% |

| SiC Content (%): | 0.1~1.4% | Model Number: | Customer's Requirement | Brand Name: | cnbm |

Packaging & Delivery

| 1. 25KG or 50KG bag inside, jumbo bag outside or pallet 2. Wooden pallet and then polyethylene film is placed over it, finally the package is tied up with strips. | |

| Delivery Detail: | Within 20 days |

bauxite refractory powder

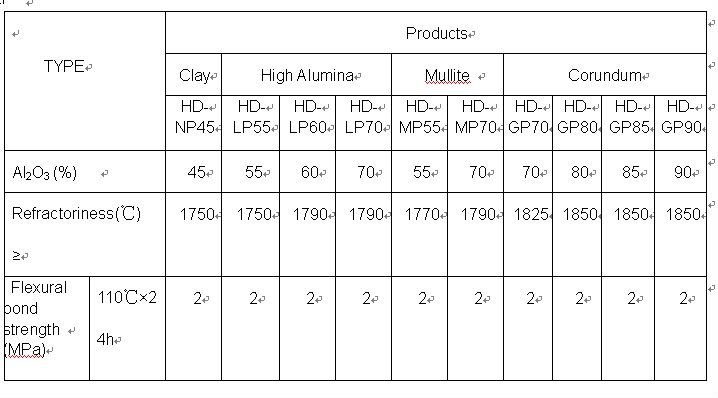

To meet the big size rotary kiln requirements, after long time research on rotary kiln refractory wearing and damage mechanism, Hongda company developed HD series rotary kiln refractory products, with advantages of good thermal stability, excellent resistance to abrasion and erosion, as well as long work life, insure the long time stable production of rotary kiln, create remarkable social and economic effects.

Our Service:

1. Your inquiry related to our products or prices will be replied in 24hours.

2. Manufacturer with large capacity, ensure the fast production cycle after confirmed the order.

3. Our professional technicians will answer your entire enquiry in patient.

4. To meet the refractory solutions, we can serve as your instructions.

5. Protection of sales area and private information for our entire customer.

If you’ve kind enquiries, please don’t hesitate to let us know. ^_^

- Q:Does anyone knows which company produces the better refractory materials?

- 1, Xinjiang Seekon new material limited liability company: Xishan Street No. 382,Saybagh District 2, Refractory Material Co., Ltd. In Xuyan, Benxi: Near the Sihu Road, Benxi City 3,Benxi Beitai new refractory material factory sales office address: Benxi city Sihu District Liu Toro No. 16

- Q:What material is refractory material?

- alumina refractory concrete, silica brick clay brick, metal ceramic, high temperature machine coating fiber reinforced ceramics, diatomite product, asbestos products, insulation board refractory. The definition of refractory can be searched in the website.

- Q:What are the requirements of refractory temperature of refractory brick?

- Refractory bricks furnace pipe material is generally divided into two types, namely, shapeless refractory material and shaped refractory. Shapeless refractory material, also known as castable refractory, is hybrid powder material made up of many kinds of aggregate or aggregate and a kind of or many kinds of binders. It must cooperate and evenly stir with a kind or many kinds of liquids during use and has strong mobility. Shaped refractory material usually refers to refractory brick whose shape has standard rules. It can also be processed temporarily during cutting according to requirement. Refractory brick, called refractory brick for short, is refractory material made by firing refractory clay or other refractory raw materials. Faint yellow or brownish, it is mainly used in building smelting furnace. It can resist 1,580 ℃-1,770 ℃ high temperature.

- Q:Who knows about the differences between 3M fireproofing materials and ShiLiDe materials?

- ShiLiDe materials are relatively poor, and have nothing to do with 3M at all. 3M is a brand! 3M company is famous for innovation around the world. It has developed a variety of products in a hundred years, involving in automotive, chemicals, telecommunications, construction and other fields. 3M automotive aftermarket has more than 3,000 products (more than 20% of which are high-tech patented products). The world's first explosionproof and heat insulating film, and the first waterproof abrasive paper were born in 3M Company. The abraser, polishing materials, mirror finish of paintwork, the internal and external auto beauty of 3M Company rank the first place in the world. 3M films are divided into conventional films and crystalline auto films. The conventional films of 3M generally have five-layer structure, the base of films is a polyester film which is s plastic film of tearing and puncture resistance. The film is coated with thermal insulation layer, ultraviolet isolation?layer, adhesive layer, wear-resistant layer, and protective layer which finally becomes thermal insulation and explosion-proof film with metal sputtering method. Optical micro-attach technology is used in the polyester?film which is the base of 3M crystalline auto film. It is coated with more than 240 layers of optical coatings in order to achieve better thermal insulation performance, and be the top anti-explosion and heat-insulating film with clear sight. I hope my answer can help you. Thank you.

- Q:The classification of fire-resistant material

- There are various refractory materials classified according to the chemical properties of material: Min< manufacturing technique: neutral refractory materials, pipes, etc. Standard model: baidu.hiphotos;8 simatic carbon composite refractory material zirconia based refractory material special fire-proof material 6; or a acute angle of 50~70° and material forms. 3.

- Q:Which schools are the best schools in the world for learning knowledge about refractories?

- Wish it helps you out.

- Q:I would like to ask a friend that how much is the fire endurance of level A fireproofing glass?

- the fire endurance of fire window is: class A window is not less than 1.2 hours, class B window is not less than 0.9 hours, Class C window is not less than 0.6 hour. technical requirements: 1, materials and accessories (1) the window frame is made by a certain strength of steel frame or wooden frame which is sufficient to safeguard the integrity and stability. (2) steel frame and mound layer can select galvanized?steel?sheet or stainless steel plate. Its selection standards should be in line with the provisions of Article 5.1. in GB12955 "Steel Fireproof Door General Technical Condition" (3) the selection standards of wood frame and mound layer should be consistent with the provisions of Article 5.1.1. in GB14101 "General Technical Conditions of Wooden Fireproof Door" (4 ) the inner filling material of steel and wood frame should be non-combustible material. (5) fireproofing glass can choose the qualified products in fire resistance test and not affecting the fire windows. light transmittance of glass is not less than 75% of identical layers of ordinary plate glass. ( 6) a sealing material between the frame and the fireproofing glass should use the nonflammable material, it can play the role of fireproofing and smoke insulation in the fire disaster. I hope I can help you

- Q:I would like to know if there is any requirement for refractories in the crucible type high-frequency smelting furnace Worry! I hope you can help me! This time!

- High enough for high temperature resistance. Refractory materials for crucibles shall be subjected to a high temperature greater than 1700 DEG C and the softening temperature shall be greater than 1650 DEG c;

- Q:What's the fire endurance of hollow brick?

- This question is really very simple. It is better no to exceed 1050℃, or it will be easily burnt. I think 980 ℃ is ok in reality. It depends on how thick your wall is because fire endurance of hollow brick is related to wall thickness. 24 wall can generally endure for 3 hours or more.

- Q:what's the classification of fireproof and thermal inuslation matertial?

- Inorganic thermal insulation material can do it, such as glass wool,rock wool,foam glass,etc. phenolic foam materials in organic foam material is special. phenolic foam not only has good thermal insulation properties but also can be composited with steel plate and other materials, A class thermal insulation materials that reach A class combustion performance include: rock (mine) wool, foam glass, EVB, etc. thermal insulation materials with A class combustion performance mainly include: phenolic aldehyde,gelatine powder polyphenyl granule, etc. thermal insulation material of fire barrier zone can use rock (mine) wool, foam glass, EVB and other materials with A class combustion performance.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Purity Calcined Bauxite Powder with Good Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords