Green PVC Conveyor Belt with Punching Hole

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

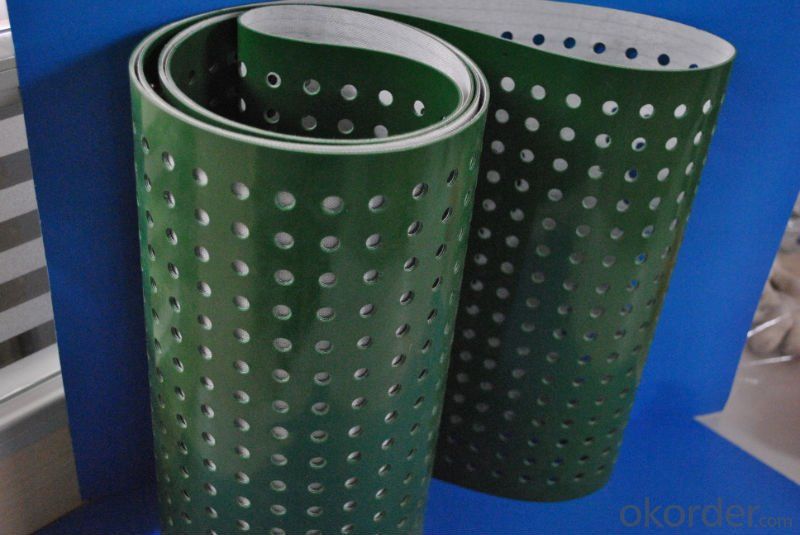

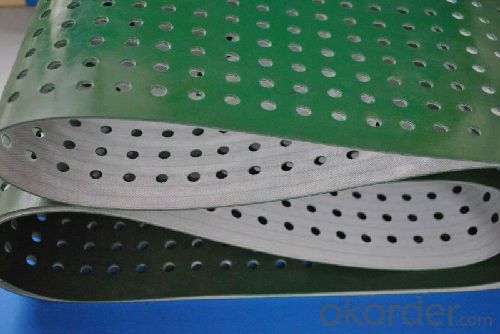

PVC Conveyor Belt with Punching Hole

A layer of cloth and a layer of glue, two layers of cloth and two layers of glue, three layers of cloth and three layers of glue, and so on. It can be customized according to your requirements.

Colors:

Red, yellow, green, blue, gray, white, black, blue, green, transparent (in general we have)

Thickness:

PVC (1~7mm) PU (0.8~4mm)

Appearance:

flat surface, diamond pattern, lawn pattern, golf pattern etc.

Advantages:

PVC: economical and practical, technology is mature. Non-toxic, odorless, environmentally friendly.

PU: abrasion resistant and corrosion.

Application:

PVC: Food, medicine, electronics, tobacco, printing, packaging, textile and other production lines belt.

PU: Most applicable to the food industry and other industries .

Subsequent machining technology:

it can add baffle, skirt, sponge, guide bar and etc.

1.High tensile strength, well circumnutate properties, light, thin, pliable but strong, oil resistant,non-toxicity,hygiene,easy clear.

2. Abrasion resistance,anti physical aging.

3. Acid/alkali resistant,cutting resistant,small turning radius.

4. It can be added V-type conducting bar underside and conducting bar or baffle on the surface.

5. Colors:white and green,etc.

6.Different thickness and width.

7.Appearance:high gross surface,matte,mainly used in food industry.

PVC/PU CONVEYOR BELT APPLICATION AREAS

Office automation equipments

Medical equipment

Packaging machinery

Swimming pool cleaning robots

Plotters

Money changers

Optical instruments

Robotic arms

Electric appliances

Vacuum systems

Vending machines

Food machinery

Textile machinery

DIY equipments

Product Photos

FAQ

Q: Can you do OEM?

A: Yes, we can do OEM products based on your requirements.It's no problem.

Q: How can I get some samples?

A: 1, We are honored to offer you samples. New clients are expected to pay for the courier cost, the samples are free for you, this courier cost charge will be deducted from the payment for formal order.

2, Regarding the courier cost: you can arrange a RPI (remote pick-up) service upon Fedex, UPS, DHL, TNT, etc. to have the samples collected; or inform us your DHL collection account. Then you can pay the freight direct to your local carrier company.

Q: How do you do regarding quality control?

A: Quality is priority? We always attach great importance to quality controlling from the very beginning to the very end:

1)All raw material we used are environmental-friendly;

2)Skilful workers care every details in handling the producing and packing processes;

3)Quality Control Department specially responsible for quality checking in each process.

Q.What are your payment terms?

A: Standard payment terms are 30%T/T,and balance payment before shipment.

L/C at sight is acceptable

Other payment terms can be negotiable.

If you want to find more details about the PVC conveyor belt, you could make an Inquiry in okorder.com. Okorder.com provides you the products with best price and quality!

- Q:How many kinds of plastic materials are there?

- According to the different uses of plastics is divided into general and engineering plastics in general plastic refers to the yield, low price and wide application range of plastics, mainly including polyolefin, PVC, polystyrene, phenolic and aminoplastic five varieties. Many of the products used in everyday life are made from these general plastics. Engineering plastics are plastics that can be used as engineering structural materials and instead of metals to make machine parts and components. Such as polyamide, polycarbonate, POM, ABS resin, PTFE, polyester, polysulfone, polyimide and so on. Engineering plastics has the characteristics of low density, high chemical stability, good mechanical properties, excellent electrical insulation, easy processing, widely used in automobiles, electrical appliances, chemical industry, machinery, instruments, and other industries, is also used in space navigation, missiles, etc..

- Q:How do you prevent olive nets from getting caught on nearby structures or obstacles?

- One effective way to prevent olive nets from getting caught on nearby structures or obstacles is by properly securing and tensioning the nets. Ensuring that the nets are tightly secured and evenly stretched across the olive trees helps minimize the chances of them getting tangled or caught on anything. Additionally, regularly inspecting the area for potential hazards or obstructions, and clearing them beforehand, can further reduce the risk of entanglement.

- Q:Do olive nets require any special installation techniques for densely planted groves?

- Yes, olive nets do require special installation techniques for densely planted groves. In order to effectively protect the olives from birds and other pests, the nets need to be installed tightly and securely to cover the entire grove. This may involve using additional support structures like poles or wires to ensure the nets are properly suspended above the trees. Additionally, it is important to consider the spacing and positioning of the trees to ensure that the nets can be installed and removed easily without causing damage to the plants or the nets themselves.

- Q:How do olive nets prevent damage from herbicide drift?

- Olive nets prevent damage from herbicide drift by acting as a physical barrier between the olive trees and the surrounding environment. These nets are typically installed above the trees, creating a shield that intercepts and blocks the herbicide particles or droplets that could potentially drift from nearby fields or areas where herbicides are being sprayed. This prevents direct contact of the herbicides with the olive trees, reducing the risk of damage or negative effects on their growth and productivity.

- Q:How do olive nets help in reducing the risk of weed competition?

- Olive nets help in reducing the risk of weed competition by acting as a physical barrier that prevents weed seeds from reaching the soil and germinating. This effectively reduces the available space for weeds to grow and compete with the olive trees for nutrients, water, and sunlight. Additionally, olive nets can also shade the soil, limiting the conditions necessary for weed growth.

- Q:How do olive nets affect the overall oil content of the olives?

- Olive nets have a minimal impact on the overall oil content of the olives. These nets are primarily used to prevent the olives from falling to the ground and getting damaged, rather than directly affecting their oil content. The oil content of olives is mainly influenced by factors such as olive variety, ripeness, and growing conditions, rather than the use of nets.

- Q:Do olive nets affect the taste of the olives?

- Yes, olive nets can affect the taste of olives. When olives are left on the tree for a longer period of time to ripen, they tend to have a richer and more flavorful taste. However, using olive nets to harvest olives can speed up the process and result in slightly less ripe olives, which can impact their taste.

- Q:What's the way to clean the greasy food on the plastic?

- Cleaning of heavy greasy plastic products: same method, but the soaking time should be more than 4 hours.

- Q:How can a plastic foam be used?

- The use of foamed plastics to life, plastic products have a very wide range of applications, especially in packaging and new materials, it has a very good use. The utility model can recycle and save energy, and can not cause white pollution to the environment. Can make all kinds of new materials: plastic foam box, gasket sheet, insulation insulation material, plastic foam board, etc., with surface buffering, heat preservation, rust prevention, moisture-proof, waterproof, breathable and so on.

- Q:Do olive nets require any special treatment before installation?

- Yes, olive nets usually require some special treatment before installation. It is important to ensure that the nets are clean and free of debris, as any dirt or leaves can affect their effectiveness. Additionally, the nets should be checked for any damages or tears and repaired if necessary. Proper storage and handling of the nets is also important to prevent any damage or tangling.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Green PVC Conveyor Belt with Punching Hole

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords