Geotextile Filter Fabric Construction Companies

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

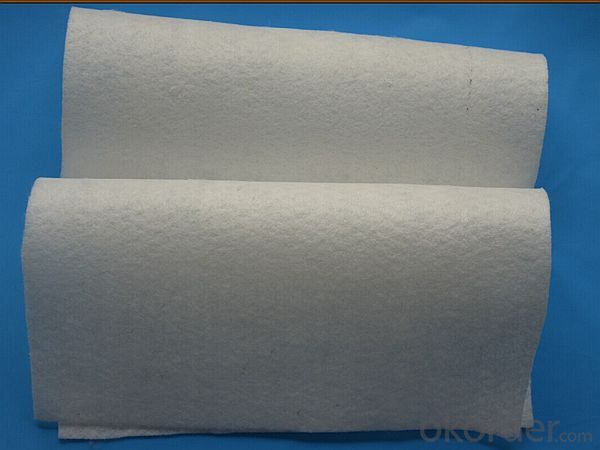

Type:

Geotextiles, Nonwoven Geotextile woven Geotextile

Place of Origin:

Shandong, China (Mainland)

Brand Name:

CMAX

Model Number:

CMAX-S001

Geotextile Type:

Non-Woven Geotextiles Woven Geotextiles

Width:

1m-8m

Length:

Customer Requirment

Weight:

100g/m2-1500g/m2

Geotextile Fabrics - the oldest and most commonly used geosynthetic today - are engineered to provide cost-effective solutions to meet specific design requirements. And although there are at least 80 specific 'applications' for geotextiles that have been developed, a geotextile always performs at least one of five discrete 'functions':

Separation

Reinforcement

Filtration

Drainage

Protection

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

specifications

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q:Geotextile Model PP200-4-750 What does it mean?

- Is the geotextile 200g / ㎡? Geotextile is generally based on the weight per unit area to divide the specifications. Geotextile manufacturers Zhang Ming Chao for you to answer, I hope to help you.

- Q:How to judge the geotextile test results are reliable

- Determine whether the tensile test results of the material are reliable, depending on whether the tensile process of the material to be tested during the test has reached the state required by this detection method. As a tensile test, to test the tensile strength and elongation of the material under specified conditions. Stretching process, the material to be tested to be uniform force, the test machine fixture holding the sample to be solid, the sample does not produce slip nor be caught damage. This is the test process of the requirements of the test machine fixture and the installation of the sample requirements, only to meet this requirement and other requirements, the test results may be accurate. Geotechnical composite materials - Geosynthetics - Staple acupuncture non - woven geotextiles GB / T-1998 Geosynthetics - Filament spunbonded acupuncture non - woven geotextiles GB / T - 1998 Geosynthetics Geosynthetics - Geosynthetics - Geosynthetics - Geosynthetics - Geosynthetics - Geosynthetics - Geosynthetic materials GB / T - 1998 Geosynthetics - Geological synthetic materials Polyvinyl chloride geomembrane GB / T-1999 Geosynthetics Plastic geogrid GB / T-1999 Geosynthetics Plastic flat wire braided geotextiles GB / T-2002 Geosynthetics Plastics 3D geogrids GB / T-2002 geosynthetics / outer composite geotextile

- Q:What are the factors to consider when designing geotextile-reinforced slopes?

- When designing geotextile-reinforced slopes, several factors need to be considered. These factors include the type and strength of the soil, the slope angle, the water conditions, the expected load and stress on the slope, the desired vegetation cover, and the available space for construction. Additionally, the design should account for the potential for erosion and the need for drainage to prevent water buildup. The selection of appropriate geotextile materials and installation techniques is also crucial for ensuring long-term stability and effectiveness of the reinforced slope.

- Q:Welding of impervious geotextile

- 1. Seam processing is the key to the construction process, the general use of heat welding method, PE film surface heat treatment, so that the surface melting, and then through the pressure, so that one fusion. 2. For the laying of a good geomembrane, edge seams require no oil, water, dust and so on. 3. Before welding to adjust the seam at the two sides of the PE single film, so that a certain width of the lap, lap width is generally 6 ~ 8 cm and smooth, no wrinkles. 4. Use special welding machine for welding. Welding construction effect map:

- Q:How do geotextiles help in stabilizing railroad tracks?

- Geotextiles help in stabilizing railroad tracks by providing reinforcement and separation between the track components and the underlying soil. They prevent the mixing of soil particles with the track ballast, which can lead to track settlement and degradation. Geotextiles also distribute the load of passing trains more evenly, reducing the risk of track deformation and improving overall stability.

- Q:How are geotextiles affected by chemical exposure?

- Geotextiles can be affected by chemical exposure depending on the specific chemical involved. While some chemicals may have no significant impact on geotextiles, others can cause deterioration, degradation, or weakening of the material. It is crucial to consider the chemical compatibility of geotextiles when they are exposed to potentially harmful substances to ensure their performance and longevity.

- Q:What are the key considerations for geotextile installation in areas prone to landslides?

- The key considerations for geotextile installation in areas prone to landslides include: 1. Site evaluation: Conduct a thorough assessment of the site to understand the slope stability, soil conditions, and potential triggers for landslides. This will help determine the appropriate type and strength of geotextile needed. 2. Design and engineering: Engage geotechnical engineers to design a tailored solution based on the specific needs of the site. They will consider factors such as slope gradient, soil type, and expected loads to determine the appropriate geotextile specifications. 3. Drainage management: Proper drainage is critical to prevent water accumulation, which can increase the risk of landslides. Geotextiles can be used to enhance drainage by allowing water to pass through while retaining soil particles. 4. Anchoring and securing: Geotextiles should be securely anchored to the slope to ensure stability. This may involve using appropriate anchor systems or integrating the geotextile into the existing slope or retaining structure. 5. Monitoring and maintenance: Regular monitoring is essential to identify any signs of distress or movement in the slope. Timely maintenance and repair of the geotextile system can help prevent potential failures and ensure its long-term effectiveness in landslide-prone areas.

- Q:Sponge city sunken green land in the drilling drainage jacket how to set the amount of geotextile

- Need plastic blind ditch, complete specifications, collar Xiang new materials for your answer

- Q:Can geotextiles be used in waste storage facility applications?

- Yes, geotextiles can be used in waste storage facility applications. Geotextiles can provide several benefits in waste storage facilities, such as erosion control, filtration, and separation of different layers of waste materials. They can also help to improve the stability and performance of waste storage structures by reinforcing the soil and preventing the migration of fine particles.

- Q:Are geotextiles suitable for use in reservoir lining?

- Yes, geotextiles are suitable for use in reservoir lining. They are commonly used to prevent soil erosion and provide stability in various civil engineering applications, including lining reservoirs. Geotextiles can help to separate different soil layers, reinforce the reservoir lining, and enhance its overall integrity and durability. Additionally, they can provide filtration and drainage properties, which can be beneficial in reservoir construction and maintenance.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Geotextile Filter Fabric Construction Companies

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords