Galvanized Steel Coil with Best Quality Good Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof Walls

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

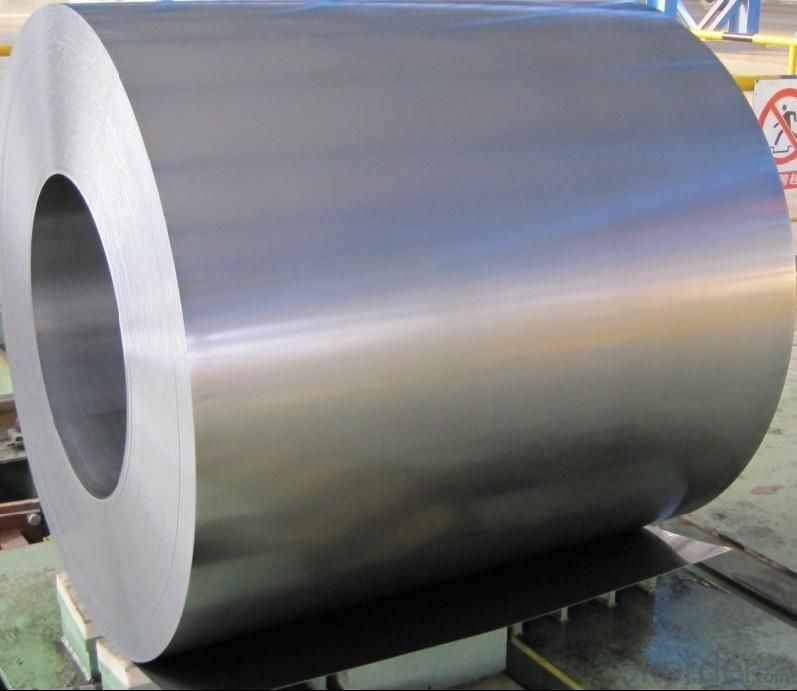

3.Hot-Dip Galvanized Steel Sheet Images:

4.Hot-Dip Galvanized Steel Sheet Specification:

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

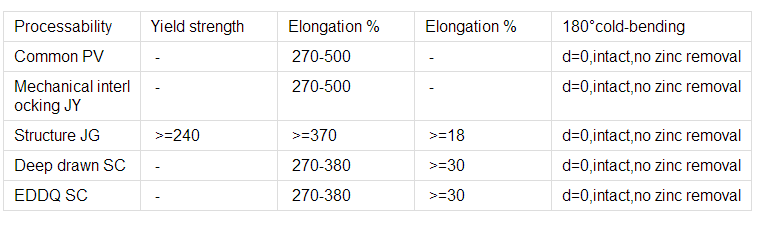

Technology test results:

5.FAQ of Hot-Dip Galvanized Steel Sheet:

We have organized several common questions for our clients,may help you sincerely:

1.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q:What are the different methods of forming steel coils?

- Steel coils can be formed using several methods, depending on their specific requirements and applications. These methods comprise hot rolling, cold rolling, and continuous casting. The most commonly used method for forming steel coils is hot rolling. This involves heating the steel billet or ingot to high temperatures and passing it between a series of rollers to reduce its thickness and shape it into a coil. Typically, this process is carried out above the recrystallization temperature of the steel, which allows for better shaping and improved mechanical properties. On the other hand, cold rolling is performed at or near room temperature. It entails passing the steel through a series of rollers to reduce its thickness and shape it into a coil. Cold rolling is often utilized to produce steel coils with precise dimensions and excellent surface finish. Additionally, it can enhance the strength and hardness of the steel. Another method for forming steel coils is continuous casting. This involves pouring molten steel into a continuous casting machine, where it solidifies into a strand. The strand is then continuously fed into a series of rollers, which shape it into a coil. Continuous casting offers several advantages, including improved efficiency, reduced energy consumption, and better control over the steel's composition and quality. In addition to these primary methods, there are various secondary processes involved in forming steel coils. These processes encompass pickling, annealing, and coating. Pickling is used to remove any rust or scale from the surface of the steel, ensuring a clean and smooth finish. Annealing involves heating the steel to a specific temperature and then slowly cooling it, which improves its ductility and reduces internal stresses. Coating is often applied to steel coils to provide corrosion resistance or enhance its aesthetic appeal. To summarize, steel coils can be formed using different methods such as hot rolling, cold rolling, and continuous casting. Each method offers distinct advantages and is chosen based on the specific requirements of the steel product. Additionally, secondary processes like pickling, annealing, and coating are employed to further enhance the quality and performance of the steel coils.

- Q:Can steel coils be coated with anti-slip materials?

- Yes, steel coils can be coated with anti-slip materials.

- Q:basically a builder told us steel is good but when we got MFI, BQ they only have acrylic

- Steel is expensive and heavy - the porcelain finish can be chipped and scratched. Yes it is colder - like your cook pots. Acrylic is cheaper, lighter and easier to handle for the installer. It can get scratched. There are companies that can refinish an old tub by putting an acrylic liner over it instead of removing and replacing the old steel ones. Acrylic has come a long way. But I still prefer steel.

- Q:Are steel coils used in the oil and gas industry?

- Yes, steel coils are commonly used in the oil and gas industry for various applications such as pipeline construction, storage tanks, and drilling equipment. The strength, durability, and corrosion resistance of steel make it an ideal material for handling the demanding conditions in this industry.

- Q:can anyone tell me the way to bring back the shine to the stainless steel kitchen sink . It has become dull.

- A stainless steel kitchen sink is durable, easy to keep clean and disinfect, and will only grow more beautiful with age - if you take proper care of it. Clean the sink with soapy water, or a stainless steel cleaner (Spray N Sheen Stainless Steel Cleaner/Polish/Protectant) once or twice a week. Once or twice a month, fill the sink half full with a 50/50 solution of bleach and water or a special stainless steel cleaner (Stainless Steel Cleaner). Let it soak for about 15 minutes, then wash the sides and bottom and let it drain. Remember to wipe dry when done.

- Q:I want to make a lap steel guitar in my wood tech class. can anyone give me a link to a video or site that has steps on how to build one.

- Steel guitars have cables attached to foot pedals to change the sound. I don't know how this would work with the top resting on your lap.

- Q:What are the main characteristics of galvanized steel coils?

- The main characteristics of galvanized steel coils include high corrosion resistance, durability, and a shiny, metallic appearance. Galvanized steel coils are coated with a layer of zinc, which acts as a protective barrier against rust and other environmental factors. This coating also enhances the strength and longevity of the steel, making it suitable for various construction and manufacturing applications. Additionally, galvanized steel coils have excellent formability, allowing them to be easily shaped and fabricated into different products.

- Q:basically all the info you can find about s1 tool steel i found a bunch about annealing, and hardening, tinsel strength and stuff like that but i need MORE!!!!!

- s1 tool steels (also calles high-speed steels) are used in the manufacture of cutting tools such as drills, reamers, taps, milling cutters, and lathe cutting tools. They are made from different types of steels. They are generally used in machine shops for making holes. .

- Q:What is the difference between carbon steel and spring steel?? And which is the better one to make swords with??

- High Carbon Spring Steel

- Q:How are steel coils used in the manufacturing of automotive accessories?

- Steel coils are used in the manufacturing of automotive accessories as they are processed and shaped into various components such as brackets, frames, and supports. These coils are typically cut, molded, and stamped into specific shapes before being assembled into the final product, adding strength and durability to the accessories.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Galvanized Steel Coil with Best Quality Good Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords