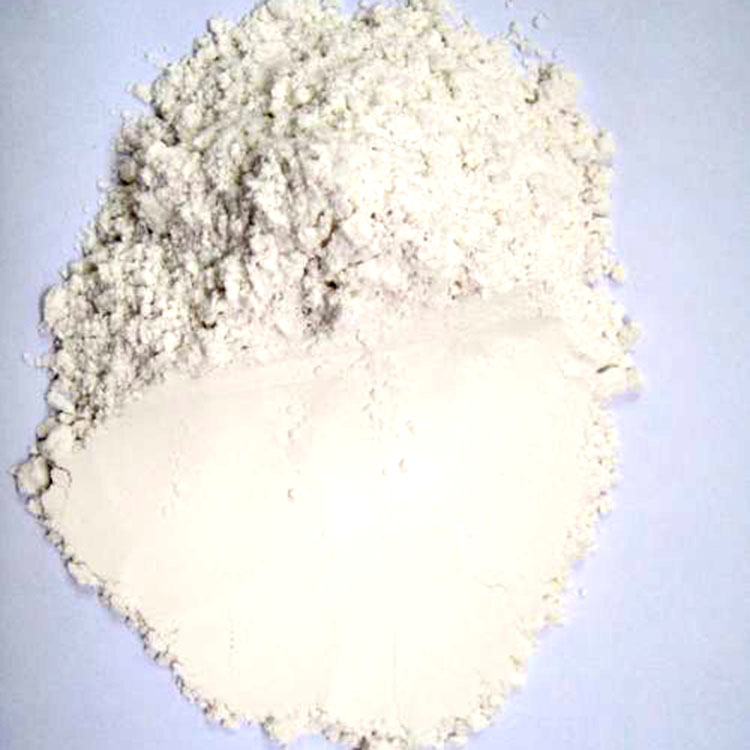

FUSED SILICA FOR REFRACTORY 3-5MM

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PRODUCT INFORMATION | |

Item | Fused Silica Powder |

Size | D50=9~11um |

Application | Epoxy insulation encapsulant material / Epoxy Molding Compound (EMC), Copper Clad Laminate (CCL), Electromagnetism Industry, Electronic Industry, Ceramic Industry, The Aerospace Industry, Glass Industry, Plastics Industry, Grinding Material Industry, Coating Industry, Investment Casting Industry, Thermal Insulation Product of Calcium Silicate, Refractory Material |

Model No. | R610 |

MOQ | 5 ton |

Material | natural silica rock after melting |

H.S. CODE | 25061000 |

PRODUCT CHEMICAL COMPOSITION AND PHYSICAL PROPERTIES | |

SiO2 | >99.99% |

Al2O3 | <0.015% 1000ppm |

Fe2O3 | <0.002% 50ppm |

Density | 2.2 |

Whiteness | >92% |

Moisture content | <0.05% |

Mohs hardness | 6.5 |

Igniting loss | <0.12% |

Appearance | powder |

- Q:what should be paid sttention when buying the refractory?

- solve the resources and the cost as much as possible. Accurate understanding and knowing the material temperature changes of various partsin order to choose the appropriate refractories. 4: 3, work performance, for example, take measures to ensure the overall life, and it is a very good buying principles: melting in high temperature metal erosion. These are the four major problems to consider when using refractory. You can choose low prices and low transportation costs of materials to meet the basic principles under the conditions described above. 2.carefully observe the material to prevent the desturction and reducing the costs. according to the structure of furnace, reasonable coordination of all parts of the material, fully take the advantages of material characteristics and strive to develop the recycle, to avoid the destruction of the materials.1. the working characteristics and the sport condition and analyze the reason of destroying the material, which can not only gurantee the product quality and reduce the expenses, get familiar with the chemical component and physics of the material.

- Q:what grades are fire resistance of fireproofing glass divided into?

- According to the fire resistance levels, it can be divided into three categories: Class A, it's a kind of fireproofing glass that can satisfy the requirements of refractory integrity, refractory and thermal insulation at the same time. This kind of glass has the properities of transmittance,fireproofing(smoke insulation, fire resistance, and keeping out thermal radiation), sound insulation, shock resistance. Class B, it's a kind of fireproofing glass that can satisfy the requirements of refractory integrity, refractory and thermal insulation at the same time. Such kind of fireproofing glasses mostly are composite fireproofing glasses and has characteristics of transmittance,fireproofing and smoke insulation. Class C, it's a kind of fireproofing glass that only satisfies the requirements of refractory integrity. This kind of glass has characteristics of transmittance, fireproofing, smoke insulation and high strength,etc.

- Q:What problems should be paid attention to while using refractory materials under a controlled atmosphere?

- Pay attention to the performance of the materials, and the use of non oxide materials!

- Q:Pals who know something about fire resistant material please tell me how many types of refractory material there are

- Classified into ordinary and special refractories. The ordinary refractory material is calssified into acid, neutral and alkaline according to the chemical property. Special refractory material is calssified into high temperature oxide according to the composition for , infusible compound and high temperature composite in addition, can be divided into ordinary refractory products according to the fire intensity (1580 ~ 1770 DEG C), high-grade refractory products (1770 ~ 2000 DEG C) and special refractory products (2000 DEG C above). According to the products shape can be divided into bulk (standard brick, special-shaped brick block, special shape (crucible, sagger, pipe, etc), fibrous shape (silicates of aluminum and zirconium oxide and boron carbide matter) and irregular shape (fireclay, refractory castables and incompletely material).

- Q:What are the requirements for the performance of refractory materials?

- Refractory materials should have very high refractoriness, high temperature heat load and resistance to softening, melting; with high volume stability, resistance to high temperature and heat load, volume shrinkage and only uniform expansion; high strength at room temperature and high temperature strength, high load softening temperature, under the joint action of heat load and heavy load, no loss of strength, creep collapse; Electric furnace analysis should have good resistance to thermal shock, resistance to rapid temperature changes, no crack, not flaking; with excellent slag resistance.

- Q:Can I use ordinary cement with the addition of sand, clay, and salt as refractory material to paste the stove?

- You can add some hair, sand, yellow mud and some salt, but don’t use cement, it would lead to a thermal explosion.

- Q:How to hang the suspended brick in the refractory masonry?

- First you can weld the metal fastener of the suspended brick and then hang up the brick.

- Q:Who can tell somthing about how to choose fire resistant rating of fire resistance rolling shutter doors?

- There is no necessary connection between them. Different fire resistant ratings of bulidings require different fire endurance of different elemements of buildings. According to the fire endurance, fireproof doors can be divided into A-grade, B-grade and C-grade, whose fire endurance should not be less 1.2h, 0.9h and 0.6h respectively. A-grade fireproof doors can be even applied to the material whose fire resistant rating is at secondary level. "Building Regulations" mention that fire resisting shutter can be used as partition of fire?compartment in those places where setting firewalls is not so easy. When using fire resisting shutter whose fire endurance doesn't include unexposed surface temperature rise, it should install closed independent automatic sprinkler system for protection on both sides, and the sprinkler sholud last at least 3 hours.

- Q:What is the appropiate thickness if fire resistant time for ultra thin steel structure coating is 2.5 hours?

- Hello steel structure can adopt surrounding concrete or brick, fireproof coating, fireproof board coating and composite structure for its fire resisitance. Fire resisitance board can be divided into thick fire protection plate and thin plate, the thickness of the plate thickness of the fire is between 20 ~ 50mm, mainly includes calcium silicate fireproof board and expansion boring stone fire board, the main varieties are KB board, CF; thin fireproof plate is between 6 ~ 15mm thick, the main varieties include enforced short fiber cement plate, ordinary enforced fiber silicate calcium board and glass cloth reinforced inorganic board.

- Q:Who knows about ranking rules of fireproofing thermal insulation materials for exterior wall?

- (1) the height of buildings is greater than or equal to 24 m, the combustion performance of thermal insulation material should be A-level. (2) the height of buildings is less than 24 m, the combustion performance of thermal insulation materials should be A- or B1-level. When using B1-level thermal insulation materials, fire barrier zone should be set in each floor. (3) incombustible materials should be used as the protective layer of thermal insulation materials. Thermal insulation materials should be completely covered by protective coatings. The thickness of protective layer should be no less than 3 mm. (4) The base walls should be set in buildings with nontransparent curtain wall structures of metal, stone,etc. The fire endurance of which should comply with relevant provisions of current fire?safety?rules on fire endurance of external wall. The fire endurance and fire protection construction of pier?between?two?windows, window sill walls, skirt walls of glass?curtain?walls should comply with relevant provisions of current fire?safety?rules on building curtain walls. (5) the internal cavity of base walls, as well as the space between the skirt wall and base walls, pier?between?two?windows, window sill walls should be sealed with fire-proof sealing materials at each floor.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

FUSED SILICA FOR REFRACTORY 3-5MM

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords