Food Grade White/Blue/Green PVC/PU Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

FOOD GRADE WHITE/BLUE/GREEN PVC/PU CONVEYOR BELT

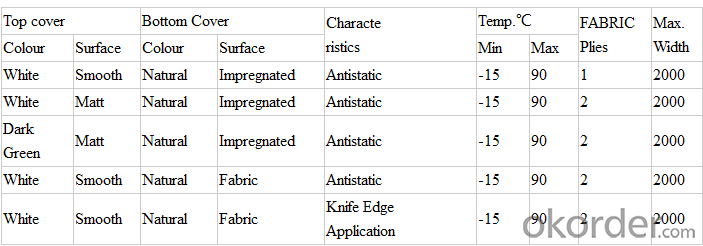

Light Duty Conveyor Belts for food industry are excellent resistant to oil and fat, non-toxic, healthy and easy to clean. The type of belts conforms with FDA, USDA and EU regulations, can be used in many applications in the following industries: bakery, confectionary, meat and poultry, fish, fruit and vegetables, dairy, agriculture etc.

PVC/PU conveyor belt/FDA

1. material: PVC/PU

2. color: white,dark green,sky bule,etc

3. surface: smooth,matt

Description:

Conveyor belt is widely used in conveyor system. Trans mission system processiry systemand Packaging conveyor ect.it has many Variety like mesh conveyor belt .

metal conveyor belt .PVC conveyor belt .Conveyor belt with skirt sidewall.hole belt.

Flat Slat POM belt. Lattice POM belt.Hard conveyor Belt.

Specification:

1.Belt curves are developed by our company has the domestic advanced technology level of quality .

2.products.Whether driven tensioning tapered roller precision machining, or the fan belt anti-deviation

adjustment

3.techniquesare reflected in the technical and process my company on the lead position.

4.Turning belt can be made into 90 °, 180 ° or even user needs at any angle. The turning radius according to the size and weight of the object conveyor may be designed to 300MM/600MM/900MM/1200MM/1500MM/2000MM/3000MM other specifications.

5.Curve conveyor belt with the straight line, to achieve the perfect

angle transporting goods during transport can maintain its relative position

synchronized conveyor. Particularly for use in the delivery of irregular items,

such as bags, bulk, small parts.

Working environment:

1. the working environment, conditions and conditions

2.Need to consider the time of day every day operation, the operating frequency, the service life of the belt conveyor, feeding and unloading methods.

3.Work environment, conditions: ambient temperature, outdoor or indoor, environmental requirements, mobile or fixed, telescopic requirements.

Product Photos

For more informations,please contact us freely,thank you.

- Q:How many kinds of plastic materials are there?

- According to the different uses of plastics is divided into general and engineering plastics in general plastic refers to the yield, low price and wide application range of plastics, mainly including polyolefin, PVC, polystyrene, phenolic and aminoplastic five varieties. Many of the products used in everyday life are made from these general plastics. Engineering plastics are plastics that can be used as engineering structural materials and instead of metals to make machine parts and components. Such as polyamide, polycarbonate, POM, ABS resin, PTFE, polyester, polysulfone, polyimide and so on. Engineering plastics has the characteristics of low density, high chemical stability, good mechanical properties, excellent electrical insulation, easy processing, widely used in automobiles, electrical appliances, chemical industry, machinery, instruments, and other industries, is also used in space navigation, missiles, etc..

- Q:Are olive nets compatible with mechanical olive harvesters?

- Yes, olive nets are compatible with mechanical olive harvesters. These nets are used to collect the olives that are mechanically shaken from the tree branches during the harvesting process. The nets are spread beneath the trees, allowing the olives to fall onto the nets, making it easier to collect and transport them efficiently.

- Q:How can plastic paint be used to prevent paint falling off?

- In addition to electricity and dust: plastic products are insulators, surface resistance is generally around 1013, easy to generate static electricity. After electrification, it is easy to absorb small dust in the air and adhere to the surface. It is very difficult to remove dust by electrostatic adsorption by general blowing method. The effect of using high pressure ionized air flow and removing dust at the same time is better.

- Q:Are there several labels for edible plastics?

- A bottle of mineral water, carbonated beverage bottleThe beverage bottle recycling don't hold waterUse: heat resistance to 65 degrees, cold resistance to -20 degrees, only suitable for warm drinks or frozen drinks, high temperature liquid, or heating, it is easy to deformation, there are harmful substances melting. And, scientists have found that after 1 months of use of plastic, may release a carcinogen, DEHP, which is toxic to the testes.

- Q:How do olive nets prevent soil erosion in the orchard?

- Olive nets prevent soil erosion in the orchard by acting as a physical barrier that traps fallen olives and other debris on the ground, preventing them from being washed away by water or blown away by wind. This helps to maintain the integrity of the topsoil, preventing it from eroding and ensuring that the roots of the olive trees remain anchored securely in the ground.

- Q:How do olive nets affect the quality of the olives?

- Olive nets play a crucial role in maintaining the quality of olives by preventing them from falling to the ground and getting damaged. These nets not only safeguard the olives during harvesting but also protect them from direct contact with soil, which can lead to spoilage and contamination. By ensuring that olives remain intact and undamaged, olive nets contribute to preserving their freshness, flavor, and overall quality throughout the harvesting process.

- Q:POM plastic flower mold how to solve?

- Plastic mold is the plastic processing industry and plastic molding machine matching, giving plastic products to complete configuration and precise size tools. Because of the plastic varieties and processing methods of various plastic molding machine and plastic product structure is simplified, so the plastic mold of the type and structure is various.

- Q:Are there any alternatives to olive nets for harvesting olives?

- Yes, there are alternatives to olive nets for harvesting olives. Some common alternatives include manual handpicking, using long-handled rakes or combs to remove olives from the branches, and mechanical harvesters that shake the trees to dislodge the olives. Each method has its advantages and disadvantages depending on factors such as tree size, terrain, and the desired quality of the harvested olives.

- Q:Are olive nets suitable for both young and mature olive trees?

- Yes, olive nets are suitable for both young and mature olive trees. Olive nets are used to protect the olives from birds and other animals, as well as to collect the olives during harvest. These nets can be easily placed over the tree regardless of its age, making them suitable for both young trees that are still growing and mature trees that are ready for harvest.

- Q:Do olive nets require any special maintenance?

- Yes, olive nets require regular maintenance to ensure their effectiveness. They should be cleaned and inspected regularly to remove debris and prevent damage. Additionally, proper storage and handling is necessary to prolong their lifespan.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Food Grade White/Blue/Green PVC/PU Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords