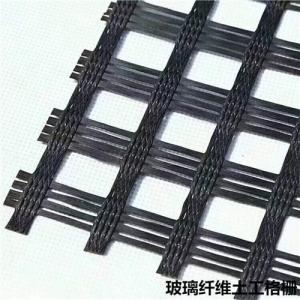

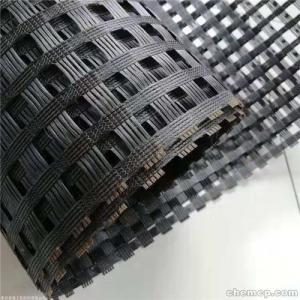

Fiberglass Geogrid with Asphalt Coating for Reinforcement

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Geogrid Description

Fiberglass Geogrid is a kind of new favorable earthwork base material to strengthen the road surface and roadbed. This product is made by weaving and covering fiberglass filament. It is featured by high vertical and horizontal tensile strength, low unit extension, high flexibility, and favorable high and low temperature resistance. The products after surface covering own the favorable property of alkali resistance and aging resistance.

Fiberglass Geogrid Specification

Tensile Strength: 25-25KN, 30-30KN, 50-50KN, 80-80KN, 100-100KN, 120-120KN,

Roll Size: 3.95x100m, as request,

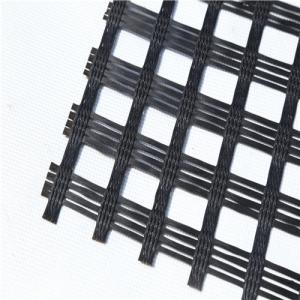

Fiberglass Geogrid Application

1) Roadbed reinforcement, prevent road surface crack.

2) Road reconstruction

3) Soft soil reinforcement, improve road whole bearing capacity and prevent crack.

Packaging & Delivery

Packaging Details: PP bags or PE film. Or Packed as customers' requests;

Delivery Detail: 10-20days after the payment received.

Remarks: we are very large fortune 500 enterprise with more than 20branches in worldwide, and have almost ten years export experience in geosynthetic field. We have kunlun bank account and have many Iran geosynthetics customers.So if any question or support, please just feel free to contact me at any time.

- Q:Are there any design guidelines for using geogrids in reinforcement applications?

- Yes, there are design guidelines available for using geogrids in reinforcement applications. These guidelines provide recommendations and specifications for the selection, placement, and design of geogrids to ensure their effective performance in soil stabilization and reinforcement projects. These guidelines consider factors such as soil type, load requirements, installation techniques, and long-term performance to ensure optimal design and functionality of geogrids in reinforcement applications.

- Q:What is the lowest price of two-way plastic geogrid?

- The cheapest non-standard 15KN the cheapest price of 2.1 this is the factory with the tax price, the general amount of words, you can also be cheaper

- Q:What are the technical parameters and testing standards of the tensile creep testing machine

- 900mm; 5 effective width: 350mm; 6: 0.03mm; precision measurement of displacement measurement error: 7 time less than 1%; 8 may refer to

- Q:Can geogrids be used for reinforcement in embankments and dams?

- Yes, geogrids can be used for reinforcement in embankments and dams. Geogrids are high-strength synthetic materials that are commonly used in civil engineering and construction projects to increase the stability and strength of soil structures. By incorporating geogrids into embankments and dams, they can effectively reinforce the soil, reduce settlement, and improve overall performance and durability of these structures.

- Q:What are the differences between geogrids and geocomposites?

- Geogrids and geocomposites are both used in soil stabilization and reinforcement applications, but they have some key differences. Geogrids are typically made from high-strength polymers or fiberglass, and they have a grid-like structure with open spaces. They are designed to provide tensile strength and distribute loads across a wider area. Geogrids are mainly used for reinforcing soils, retaining walls, and roadways. On the other hand, geocomposites are multi-layered materials that combine different geosynthetic components. They usually consist of a geotextile fabric or membrane bonded to a geogrid or geonet layer. Geocomposites offer a combination of functions such as filtration, drainage, separation, and reinforcement. They are commonly used in applications like erosion control, landfill engineering, and drainage systems. In summary, while geogrids focus on reinforcement and load distribution, geocomposites offer a more versatile solution by combining multiple functions in a single product.

- Q:Do geogrids provide reinforcement to geosynthetic asphalt liners in reservoirs?

- No, geogrids do not provide reinforcement to geosynthetic asphalt liners in reservoirs.

- Q:How do geogrids improve the performance of geosynthetic encased columns?

- Geogrids improve the performance of geosynthetic encased columns by providing additional reinforcement and stability to the column structure. They help distribute the load more evenly, enhance bearing capacity, and prevent excessive settlement or lateral movement. Geogrids also enhance the confinement of the column, reducing the potential for soil erosion and improving the overall durability and longevity of the structure.

- Q:Can geogrids be used in reinforced earth bridge abutments?

- Yes, geogrids can be used in reinforced earth bridge abutments. Geogrids are commonly used in reinforced earth structures as they provide soil reinforcement and improve the stability and strength of the structure. In the case of bridge abutments, geogrids can be used to reinforce the soil backfill behind the abutment walls, enhancing its load-bearing capacity and reducing the potential for settlement or failure.

- Q:What is the geogrid GSJ80/HP

- 4, mixed with asphalt compatible materials - glass fiber geogrid treatment process after coating is designed for asphalt mixture, every fiber is fully coated with high compatibility with asphalt, so as to ensure that the glass fiber geogrid in the asphalt layer and not in isolation of asphalt mixture but, firmly together.5, physical and chemical stability, through special postprocessing agent coating, glass fiber geogrid can resist all kinds of physical and chemical erosion wear, can resist biological erosion and climate change, ensure that its performance is not affected.6, lock and limit the aggregate because of glass fiber geogrid is mesh structure, aggregate in asphalt concrete can be run through them, thus forming a mechanical interlock. This restriction hinders the movement of aggregates, so that the asphalt mixture in the case of load can achieve better compaction state, higher load capacity, better load transfer performance and smaller deformation.

- Q:Geogrid construction must be folded back 2m wrapped in compacted packing on it?

- Edit this section of geogrid construction notesPaved geogrid should be smooth, paving layer after acceptance, to prevent longitudinal askew phenomenon, according to the width of paving layer or draw white thread, you can start paving, and then use the end of the nail fixed grid (nail 8, per meter wide uniform fixed distance) well, after the end of the fixed grid, with the paving machine will grill slowly pulled forward each shop, shop 10 meters long artificial tightening and straightening once, until a volume grating puwan, put the next volume, operation with a roll of puwan with roller 6T-10T from the starting point to begin the direction of rolling over, (steel rolling as road paving in the surface layer and the leveling layer, the machine is appropriate; such as grid laid directly on the concrete pavement, with the roller roller is appropriate) ground shop: Volume long unit as the laying of the long, the grid should be covered the long shop Full, then the overall check a paving quality, and then paving the next section, the next section of paving, grille and grille can be used lap length 10-15CM, and fixed with nails or wedge to shop in second, to the direction followed by analogy with operating requirements.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiberglass Geogrid with Asphalt Coating for Reinforcement

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords