EPS Sandwich Panel Production Line

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 set set

- Supply Capability:

- 100 set per month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of EPS Sandwich Panel Production Line

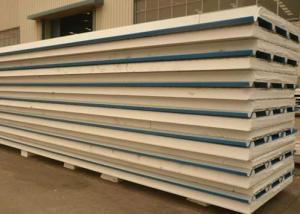

We can design the line to make different kinds of panel in appearance, for wall panels and roofing panels with various joint design. Sandwich panel, as a new building material show excellent performance on insulation. It is taking the place of brick to be a main material for building now.

Specifications of EPS and Rockwool Sandwich Panel Line

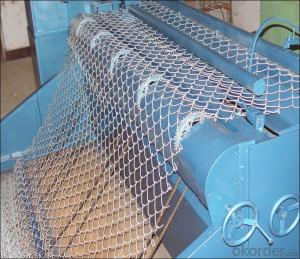

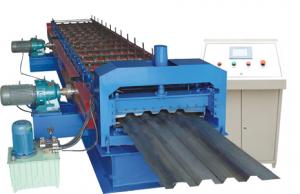

The whole line consists of uncoil device, forming system, cutting device, compounding system(beading, pasting, heating ,compounding, flanging, slotting, edging, pneumatic and auto-cutting).

Features of Sandwich composite panel line:

1. Adopting advanced technology, it combines air, electricity and machine system.

2. Adopting computer control stepless speed regulation, it is smooth in running and easy in operation.

3. According to customers' requirement, the length is controlled by the computer, with an accurate orientation.

4. Time is showed on the touch screen, counting and revising automatically.

5. The outline of the panel can be designed and revised on customers' requests.

Applications of EPS Sandwich Panel Production Line

This metal forming machine is indispensable equipment for producing the wall panel and roof panel for industrial workshops, warehouses etc.

Technical data of EPS Sandwich Panel Production Line

Sandwich panel Spec. | ||

Panel thickness | EPS Core | 40-300mm |

Rockwool | 40-150mm | |

Steel Sheet Spec | ||

Thickness | 0.4-0.8mm | |

Max. Width | 1250mm (we can design according to buyer`s requirement) | |

Max. coil weight | About 5 tons | |

Whole Line Spec. | ||

Whole line dimension | about 45000mm × 3000mm × 2800mm | |

Total weight | About 20t | |

Working speed | About 0-5m/min (adjustable) | |

The output | 1500m2-2000m2/8hour | |

Control mode | PLC and converter | |

Total power | About 32 kw (as per final designing) | |

Power required | 380V/3phase/50Hz or as per customer's requirement. | |

Suitable working temperature | About 25 degree | |

Packaging & Delivery of EPS Sandwich Panel Production Line

1. Main machine is covered by plastic film.

2. PLC computer control box, spare parts and other small parts are packed by wooden carton box.

3. Delivery:80 days

- Q:What do you want to consider if you want to buy a sandwich panel production line?

- Now there is the middle lane is a honeycomb galvanized plate board online, I know this is the direction of future development is the absolute fire, there is air, that summer is not too hot, winter is not too cold.

- Q:What does color steel sandwich board mean?

- The color steel sandwich panel product is composed of two layers of formed metal panels (or other material panels) and a macromolecule heat insulation inner core which is directly foamed and matured in the middle of the panel.

- Q:Characteristics of sandwich panels

- The utility model has the advantages of quick installation, light weight, plug in, installation and free cutting, and the installation of the utility model is simple and convenient, and the benefit and the time limit can be saved.

- Q:How to install the pre embedded pipe in the clean room sandwich panel?

- Engineering sandwich plate decoration, wall structure in construction completed, outside the installation of doors and windows, clean air conditioning indoor ceiling above the air supply pipe, various pipes, cable and wiring pipe, pipe insulation after the completion of a special decoration engineering.

- Q:Can the oil on the sandwich board be painted?

- Sandwich panels of better quality can be painted, but a decorative panel is recommended.

- Q:Polyurethane sandwich panel production line?

- Products are mainly used for exterior wall insulation and central air conditioning, air supply pipe. The working principle of polyurethane perfusion machine by measuring liquid pump in a certain proportion into the mixing head after mixing evenly pouring in sandwich bottom material, and the upper surface of a layer in the layer of transport to the press, press under the chain plates foam curing; sandwich plate after curing in the production line both sides trimmed, automatic track cutting machine cut to length of the products.

- Q:Can the sandwich board adhere to the plaster line?

- First brush on white latex (polyvinyl acetate emulsion), and then self tapping nails will be fixed on the wood board gypsum board, silk nail head must be slightly concave into the gypsum board, so as not to destroy the plaster board surface of the layer of paper for the most appropriate

- Q:Color tile and color steel sandwich plate what is the difference, the use of what is the difference?

- Also known as color: color steel tile is used in color coated steel sheet, roll cold forming pressure plate and various wave types, it is suitable for industrial and civil buildings, warehouses, special buildings, large-span steel structure house roof, walls and wall decoration etc.

- Q:What's the difference between a polyurethane sandwich panel and a foam sandwich panel?

- The production of polyurethane sandwich panel requires advanced sandwich panel continuous production line. The process is made of internal and external zinc plating (aluminized zinc), colored steel plate cold bending forming, and middle coating polyurethane rigid foam.

- Q:What are the causes of uneven surface of polyurethane sandwich panel produced by continuous production line?

- Uneven heating of sheet material leads to uneven solidification of Pu material.

1. Manufacturer Overview |

|

|---|---|

| Location | Hebei, China |

| Year Established | 2008 |

| Annual Output Value | Below US$1 Million |

| Main Markets | Eastern Europe North America Southeast Asia Africa South America North America |

| Company Certifications | ISO9001 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjin Port |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 8-10people |

| Language Spoken: | Chinese, English |

| b)Factory Information | |

| Factory Size: | 10,000square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

EPS Sandwich Panel Production Line

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 set set

- Supply Capability:

- 100 set per month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords