High Quality Sandwich panel Roll Forming Machinery -PRL-6-SA

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 500 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Quality Sandwich panel Roll Forming Machinery -PRL-6-SA

General Information:

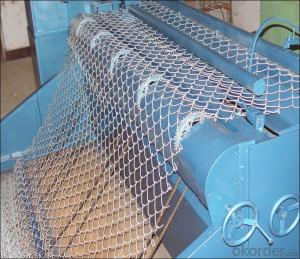

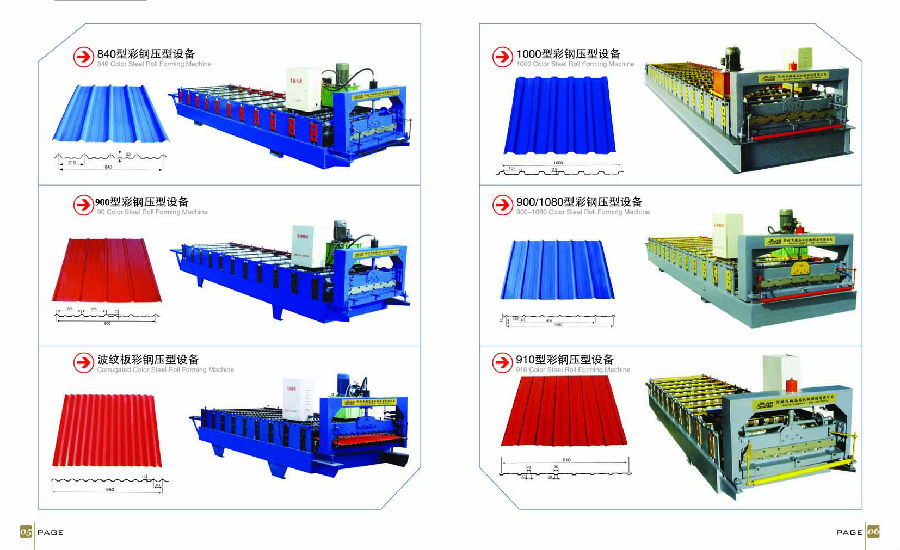

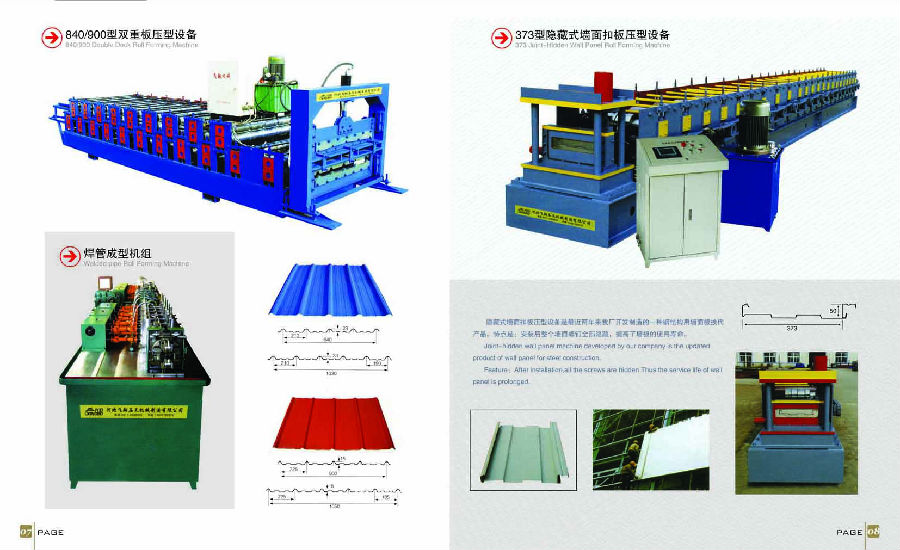

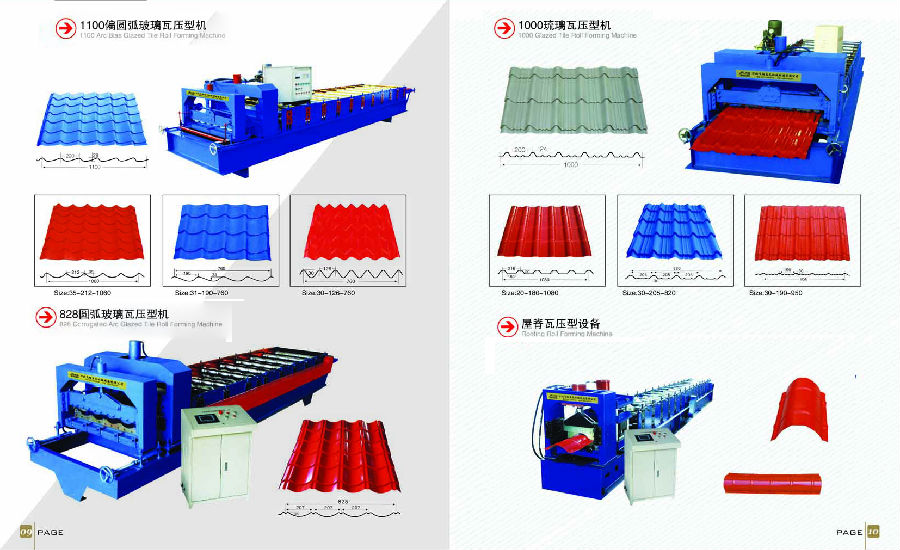

We can design the line to make different kinds of panels in appearance, for wall panel and roofing panel with various joint designs.

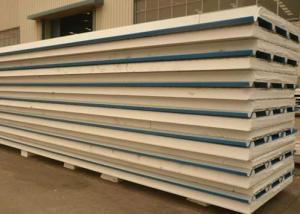

Sandwich panel, as a new building material,shows excellent performance on insulation.

It is taking the place of brick to be a main material for building now.

High speed slitting and cut to length can cut steel with thickness from 1mmto 16mm, if no need slitting thickness up to 30mm.

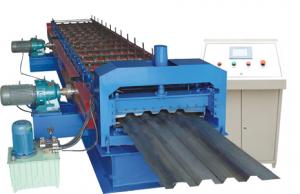

Processing flow is as following:

Carry coil→load coil→de-coiling(pressing guide +opener)→entry、rough level→cutting→transition→guide→slitting (waste winding) →looping storage→pre-separating, damping→recoiling →packing→discharging→guide→leveling→fix size (end plate feeding)→cutting→discharging

Technical Data:

1. The Manufacture Speed Of Sandwich Panel:8.6m/min( frequency conversion to adjust speed)

2. The Thickness Of Sandwich Panel:30-200mm

3. The Thickness Of Steel : 0.4-0.8mm

4. The Length Of The Production Line : about 120 meters

5. The Total Power Of The Production Line : 350 KW

6. The Length Of The Double Belt Conveyer : 24m

- Q:How can the wire laying in the foam sandwich panel workshop meet the fire protection requirements?

- Outside the wire is a pipe, that is, through the pipe laying, if the pipe is galvanized steel pipe, and buried in the wall, floor, floor and so on inside can not see, it is called galvanized steel pipe concealed.

- Q:Characteristics of sandwich panels

- The utility model has the advantages of quick installation, light weight, plug in, installation and free cutting, and the installation of the utility model is simple and convenient, and the benefit and the time limit can be saved.

- Q:What is the color steel sandwich board?

- The intermediate sandwich panel is two color steel with polyurethane foam with a layer of insulating material.

- Q:How is the sandwich plate synthesized?

- The sandwich panel is made up of two layers of metal panels (or other material panels) and a macromolecule heat insulation inner core which is directly foamed and matured in the middle of the panel.

- Q:Rock wool, color steel sandwich plate production line where good?

- Jizhong Machinery Manufacturing Co., Ltd. has won the title of state-level high-tech enterprises, and has been recognized by the Ministry of Commerce as a designated equipment export manufacturer.

- Q:Polyurethane sandwich panel production line?

- Polyurethane sandwich panel production line, namely polyurethane composite insulation board production line, is made up of two layers: cement, aluminum foil and non-woven,In the soft base material such as cloth and paper, special equipment for producing phenolic resin (polyurethane) foam sandwich board, the thickness of sandwich panel is 20-100mm, width 1200mm, length is fixed.

- Q:How to thread the EPS (color steel) sandwich panel?

- Of course, PVC flame retardant tubes, ha ha, I suggest that our company is to do foam sandwich board, the general customers are doing so.

- Q:What's the difference between sandwich board and composite board?

- The metal sandwich panel is made of two layers of metal panels (or other material panels), which are made of heat preservation material and are compounded by adhesive compound or direct foaming.

- Q:What's the difference between a polyurethane sandwich panel and a foam sandwich panel?

- The common point is that the sandwich panels are all made of hard protective coatings, and the difference is that the materials in the center are different.

- Q:What are the causes of uneven surface of polyurethane sandwich panel produced by continuous production line?

- The upper and lower track plates of the fixed polyurethane plate are not smooth, mainly because of the processing problem, the chain drive polygon effect or the equipment level is not adjusted properly;

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Quality Sandwich panel Roll Forming Machinery -PRL-6-SA

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 500 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords