Electroytic Tinplate Coil SPTE ETP for Packaging Consumer Industrial Packaging

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Electroytic Tinplate Coil SPTE ETP

Tinplate has a beautiful metallic luster as well as excellent properties in corrosion resistance and paint-ability.

Available Specifications and Sizes

| Steel Type | MR, SPCC |

| Temper (BA&CA) | T1~T5, DR8~DR10 |

| Coating | 1.1~11.2g/㎡ |

| Thickness & Tolerance | 0.15~0.5mm (Tolerance: ±0.01mm) |

| Width & Tolerance | 600~1010mm (Tolerance: +2/-0mm) |

| I.D | 508 mm |

| Coil Weight | 3~10 MT |

| Passivation | 311 |

| Oiling | DOS |

| Surface Finish | Bright, Stone, Silver, Matte, (B, R, R2, S, S1, S2, M) |

| Quantity for 20 Feet FCL | 20~25 Tons |

| Package | Seaworthy Export Standard Wooden Pallet |

Special specifications are available on customers' requirements

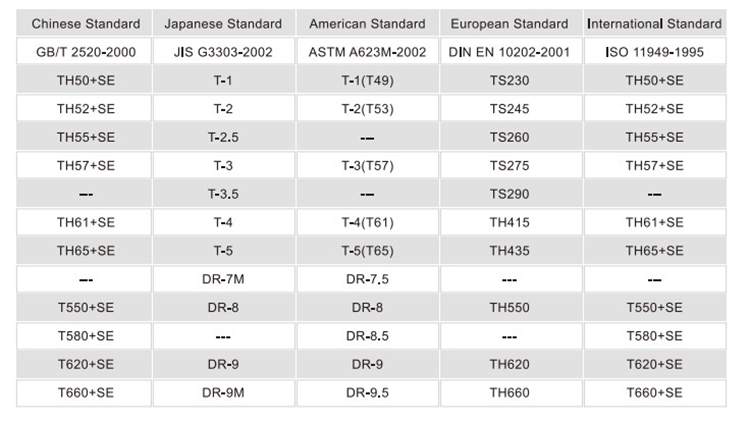

Standard Comparison for Temper

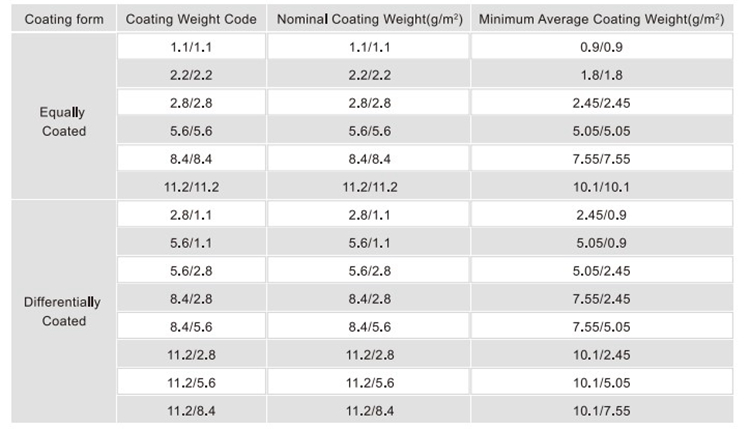

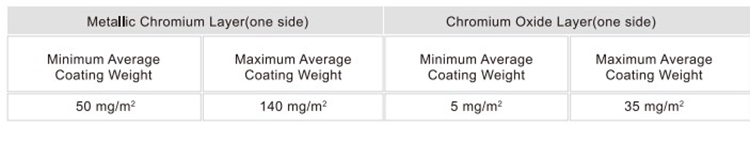

Tin coating weight

1.ETP

2.TFS

Applications of Tinplate and TFS: Consumer Packaging and Industrial Packaging

| TINPLATE | ETP is primarily used for packaging foodstuffs and beverages, but it is also used in containers for oils, grease, paints, polishes, chemicals and many other products. Aerosol containers,caps and closures are also made from ETP. |

| TFS | TFS are most frequently used for can tops, screws and lug caps, snap and press-on closures and shallow-drawn food cans. |

Miscellaneous

| in Electronics | Electrodes, Cable tape, Magnetic screen covers, etc. |

| in Engineering | Automotive oil filters. Automotive air filters, Gaskets, etc. |

| in Construction | Gas meter internal components, Heat exchangers, cookware, shelving, etc. |

Package

- Q:Can tinplate be used for packaging heavy products?

- Yes, tinplate can be used for packaging heavy products. Tinplate is a strong and durable material that can withstand the weight and pressure of heavy items, making it suitable for packaging purposes.

- Q:What is the global demand for tinplate?

- The global demand for tinplate is significant and continuously growing. Tinplate is widely used in various industries such as packaging, electronics, automotive, and construction. Its corrosion resistance, durability, and versatility make it a preferred choice for packaging materials, especially in the food and beverage sector. With the increasing population and urbanization, the demand for tinplate is expected to further rise in the coming years, driven by factors like increasing consumer goods consumption and technological advancements.

- Q:How does tinplate packaging contribute to product tamper resistance?

- Tinplate packaging contributes to product tamper resistance by providing a strong and durable barrier that is difficult to manipulate or breach without leaving visible signs of tampering. Its sturdy construction and sealed nature make it harder for unauthorized individuals to access the product, ensuring its integrity and safety.

- Q:How to test the tightness of tin metal cans?

- Pressure leakage test with a rubber plug when empty hole plugged, start the air compressor, slowly open the valve, the pressure in the tank is increased gradually, while the empty tank is immersed in the water tank, careful observation with outer bottom cover curling and welding seam has no air bubbles, until the pressure rose to 0.7jg/cm and 2min. All the same parts of continuous bubbles, should be judged as leakage, leakage of the recording time and pressure, and mark in the leak site on.

- Q:Can tinplate be used for art and sculptures?

- Yes, tinplate can be used for art and sculptures. Its malleability and durability make it a suitable material for creating various artistic forms and sculptures. Additionally, tinplate can be easily manipulated, painted, and decorated, allowing artists to explore their creativity and produce unique artworks.

- Q:What are the common widths of tinplate?

- The common widths of tinplate typically range from 600mm to 1200mm.

- Q:What are the latest innovations in tinplate technology?

- Some of the latest innovations in tinplate technology include the development of lightweight tinplate materials that offer the same level of protection and strength as traditional tinplate, but with reduced material usage. Additionally, advancements in coating technologies have allowed for the development of tinplate with enhanced corrosion resistance, ensuring longer shelf life for packaged products. Furthermore, the introduction of digital printing techniques has revolutionized the design capabilities for tinplate packaging, allowing for more intricate and customizable designs. Overall, these innovations aim to improve sustainability, product preservation, and visual appeal in the tinplate industry.

- Q:Can tinplate be shielded?

- For tinplate shielding, it is a kind of shielding material, at present 3 applications more cheap, processing is good, but the finished long-term placement of rust on the fracture surface, thus affecting the weldability, which is its only drawback. If it is placed in a short time, it will not affect weldability. Electroplating is not the best way to solve the problem. My supplier is coated with an anti rust paint on the fracture surface, and then ultrasonic cleaning is done before going on line. But I mostly use "ocean shield frame copper to make," a little expensive, but the performance is very good ^_^

- Q:What are the different types of tinplate edge finishes?

- There are three main types of tinplate edge finishes: single edge, double edge, and scroll edge.

- Q:Can tinplate be embossed or engraved?

- Yes, tinplate can be embossed or engraved.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Electroytic Tinplate Coil SPTE ETP for Packaging Consumer Industrial Packaging

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords